Hatch, is that premixed or metered through a pump ?... If your metering through a pump im curious to know how much oil your going through each ride ? 16 OZ, 24 OZ , 32 OZ ?

OT

OT

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

JSCC

I think you kind of answered your own questions. One of the reason I think a injected sled smokes way more then a non injected sled (oil). Is that a oil injected sled is just pucking oil out the side of the case right after the reeds. It leaving the fuel to pick it up and mix with it for maybe an inch before it goes into the crank. A non oil injected sled already has it mix 100% with the gas and it goes right into the motor. I think this make sense.

I'm proplay going to get flamed by the twisted crue on here for this but anyways.

First I would like to say IF I was buying a kit it would by a Twisted kit. Shain seems like a stand up guy and from the couple of dealing I had with other turbo vendors they were doing there best to screw me. Also I like supporting smaller company and not the big guys.

One thing that I dislike about the twisted kits is its charge tube mostly the airbox. I have made a couple different style airbox and I have found on the dyno (hp) and time before it makes boost. That twisted desgin all though its simple and clean takes the most pounds of boost to make the same horsepower and had a longer spool time. Remember boost in it self is a measure of restriction. Also from what I have found you are better off feeding air straight in the throttle bodys instead of on the side creates alot less turblance in the system and takes less pressure to do so.

Thats my 2 cents.

Mike

JSCC

I think you kind of answered your own questions. One of the reason I think a injected sled smokes way more then a non injected sled (oil). Is that a oil injected sled is just pucking oil out the side of the case right after the reeds. It leaving the fuel to pick it up and mix with it for maybe an inch before it goes into the crank. A non oil injected sled already has it mix 100% with the gas and it goes right into the motor. I think this make sense.

I'm proplay going to get flamed by the twisted crue on here for this but anyways.

First I would like to say IF I was buying a kit it would by a Twisted kit. Shain seems like a stand up guy and from the couple of dealing I had with other turbo vendors they were doing there best to screw me. Also I like supporting smaller company and not the big guys.

One thing that I dislike about the twisted kits is its charge tube mostly the airbox. I have made a couple different style airbox and I have found on the dyno (hp) and time before it makes boost. That twisted desgin all though its simple and clean takes the most pounds of boost to make the same horsepower and had a longer spool time. Remember boost in it self is a measure of restriction. Also from what I have found you are better off feeding air straight in the throttle bodys instead of on the side creates alot less turblance in the system and takes less pressure to do so.

Thats my 2 cents.

Mike

mike did you also test going in the top like ovs and bd ?I would think it would be the same as the side right as for the flow coming straight in ya, but on the m the charge tube is way long if ya go that way and has to bends ,A two stroke turbo good once3 told me every time you make a 90 bend its like 3 feet of straight pipe so I would have to say on a two stroke m sled the shortest charge tube would be better no matter where it comes in . I have had sleds with that style of in take and with intercoolers I use the one that works best for me on the snow and not what worked best on the dyno...

Maybe snow star will post a pic of our new shorter straighter charge tube.

I think I might be missing something, on my M8 the oil seems to be injected in the rubber boots between the throttle bodies and reeds. There is on oil line going to the fuel pump. When I pull the fuel rail off the injectors there is just raw gas in the rail and that fuel isn't mixed until after it passes through the throttle bodies. Is this wrong? I had it all apart last week and this is how it seemed to work.

Correct, if you look a few posts back (at my last post), you can see that I got my head out of its daze and corrected my statements on the oil injection..

Having only a few hours sleep, apparently effects the ole' brain function. LOL

But as far as oil ratio... less oil is NEVER a good thing IMO..

Kelsey

One thing that I dislike about the twisted kits is its charge tube mostly the airbox. I have made a couple different style airbox and I have found on the dyno (hp) and time before it makes boost. That twisted desgin all though its simple and clean takes the most pounds of boost to make the same horsepower and had a longer spool time. Remember boost in it self is a measure of restriction. Also from what I have found you are better off feeding air straight in the throttle bodys instead of on the side creates alot less turblance in the system and takes less pressure to do so.

back to the topic,

how did the water to air heat exchanger work on the OVS kit?....has anyone else tried this?...what about running the comple turbo just outside the hood and piping everything back inside?...bet that would keep the compressor cooler, but what effectr would this have on the turbine wheeel? would a colder turbine wheel effect the pipe temps?

Snow & Ice would have a huge effect on the compressor outside hatch

back to the topic,

how did the water to air heat exchanger work on the OVS kit?....has anyone else tried this?...what about running the comple turbo just outside the hood and piping everything back inside?...bet that would keep the compressor cooler, but what effectr would this have on the turbine wheeel? would a colder turbine wheel effect the pipe temps?

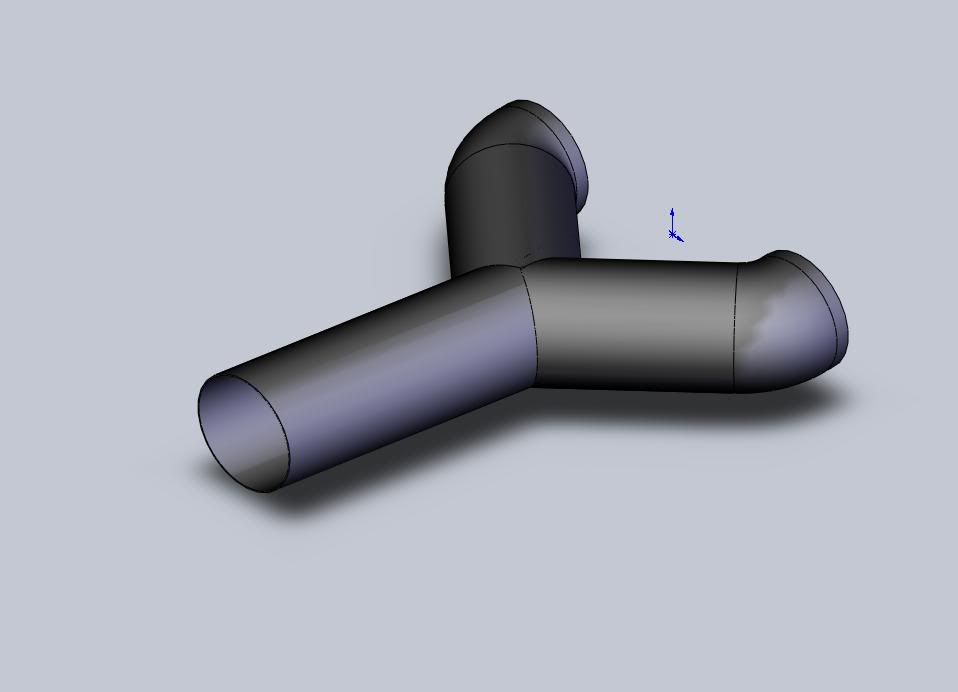

It's too bad someone dont build a charge tube the splits directly to both Throttle bodies, and rid the air box all together.....?

As far as bends, I know in the HVAC world they calculate that into footage gain as well. So I agree with Shain the amount of bends will effect performance.

It's too bad someone dont build a charge tube the splits directly to both Throttle bodies, and rid the air box all together.....?

I do and it works very well. After all my testing and 6 different manifold later that is what I came up with.