The bottom/lower half of the cylinder/engine is where these failures are occuring... The lower half of the engine runs MUCH, MUCH cooler than the upper half and is also not subjected to any combustion process (read...MUCH less stress on itself)

Most of the heat and fatigue occurs inthe upper half of the cylinder not the lower.. The failures are in the lower half...

What the lower half, as well as the upper half, share is a piston STOP and direction change.. When this occurs with the upper half (TDC) it is under VERY high pressure, when it accurs at the lower half (BDC) , it is under MUCH lower pressure.. MUCH.. Again, these failures occur on the lower half not the upper..

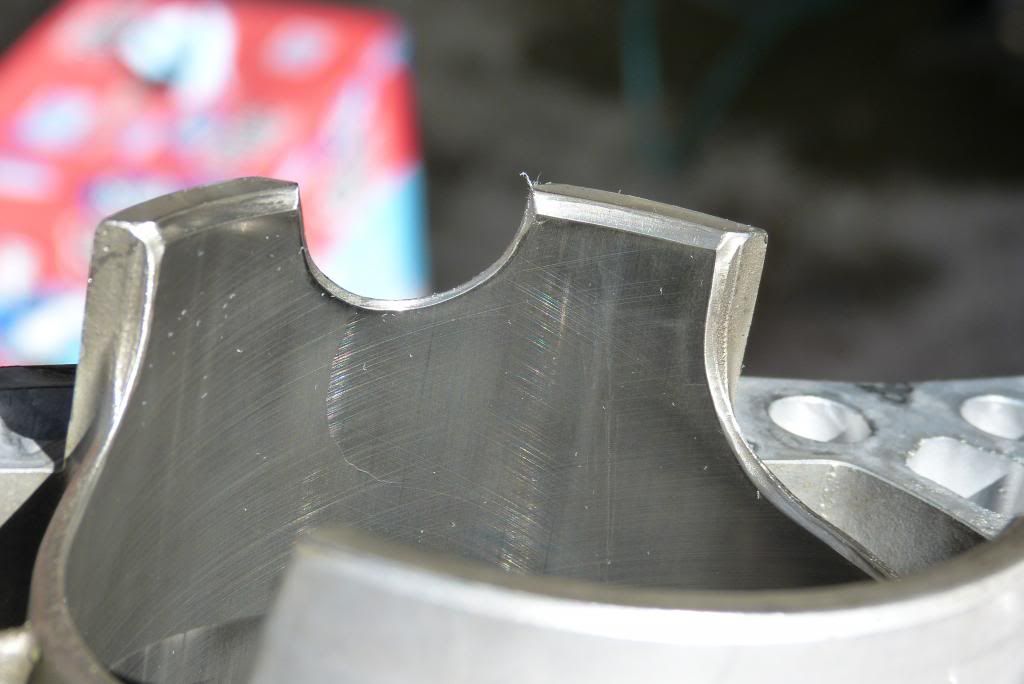

So, while the cooling design of the cylinders is not ideal, the cylinder cracking is not from this. It is from a piston (unsupported) changing directions and "smacking" the lower skirt.. If you smooth this "smack" you will fix the issue..

Polaris uses a loose piston because it has to conform to a "standard" of prolonged testing without failure in order to meet regulations.

With a normal fitting piston, this test fails.. with a loose piston , it passes..And, this is related to the cooling design.. but the failure is NOT skirt crack, but a piston seizure.. remember the early Dragons? They would seize up for no apparent reason... Then Polaris "UPDATED" your Dragon.. and the seziure lessened right along with your power!

Fix the piston and the skirt failures will diminsh.. The question is.. Is your skirt already fatigued??