Chassis Preparation and Turbocharger Installation

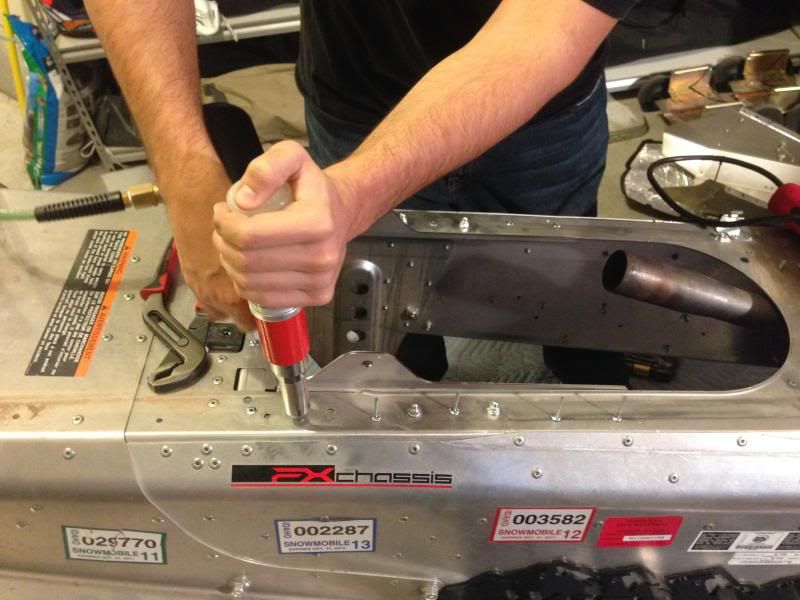

Step 40

Mount the turbo onto the OE exhaust pipe.

Now its gonna tell you to find the special non-nylock clamp. I looked everywhere for this thing!! Turned out it was actually already on the turbo further up the pipe. So dont look through everything trying to find it. Just check on the turbo and make sure its there before the turbo is slid onto the exhaust pipe.

Once you actually get the turbo on, undo the 2 M10 bolts and then mount the turbo to the U shaped bracket that was just riveted down.

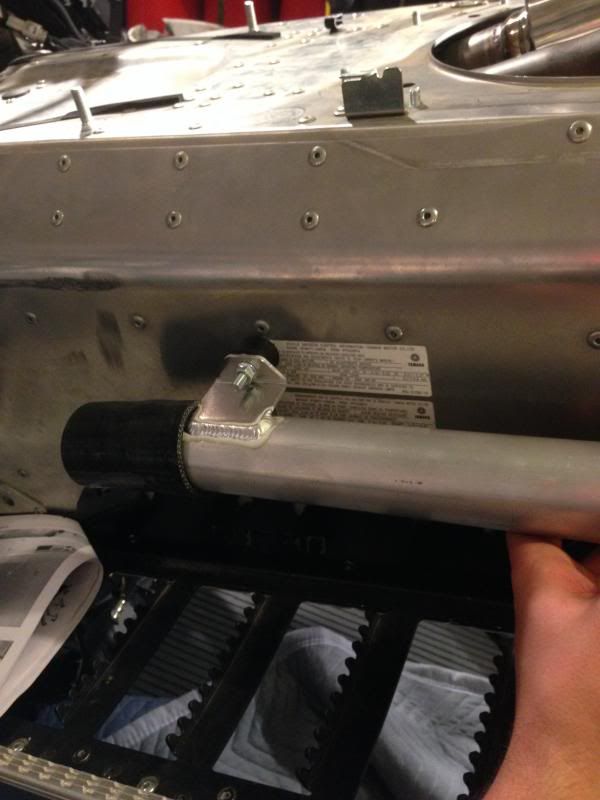

Once both sides are tightened down and set, I headed back to that T clamp and cinched that down. Make sure that it is over the cuts in the turbo inlet pipe so that when it is tightened down it pulls the cuts together and seals the two pipes together.

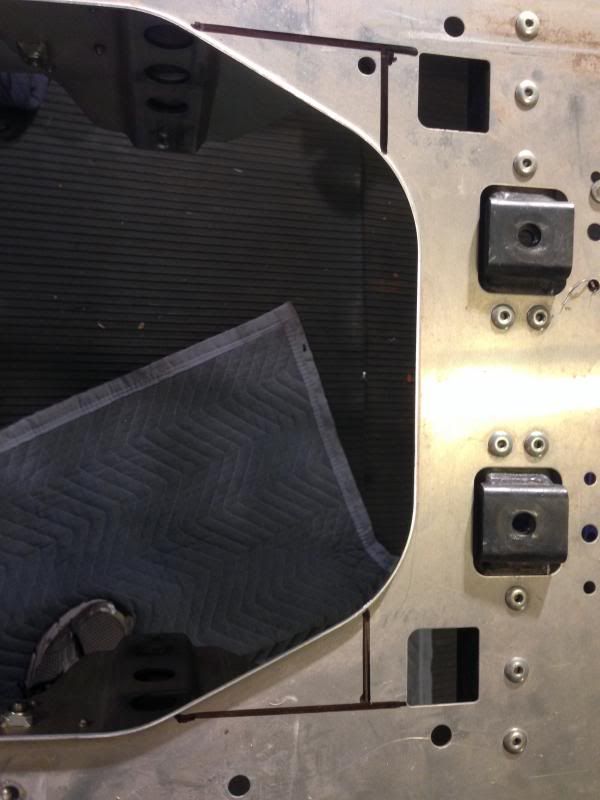

You can see the cuts here.

Insure that it is positioned like this so as to not interfere with any tubing or the track.

Lastly head back to the top of the tunnel and re-tighten the two bolts we loosened that hold the exhaust manifold along with reinstalling their rubber plugs.

With that this section is over!