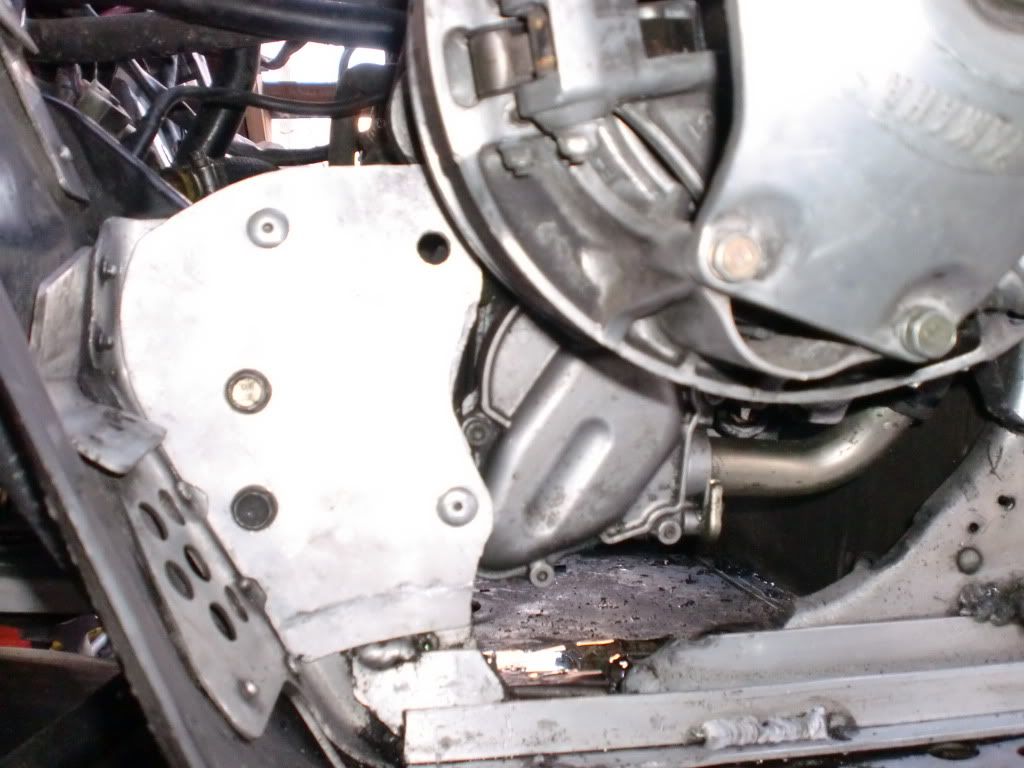

you basically summer up my issue, and im dealing with it accordingly, the issue is that if the bolt only has support on one side, it can twist the rubber mount like you said, I just need to have tabs on either side that dont allow it to do that, and I layed my rear mount on the kitchen counter(nice and level) it rocks kinda funny, the thing has a nice tweak in it by the right clutch side mount, would explain my shortened center to center issue. i am working on rebuilding the motor mounts bigger and stronger, and still somewhat light. I can also move the motor around a hair due to the fact that I no longer have a giant carb rack that is trying to clear the steering post, so that allows me to make the mounts not all tiny and twisted..

also, the ups man came today... GOT PROPANE!??? The system is stupid simple, and this is the fuel defivery system minus the tanks.

Line in from the tank throught a lockoff valve that is activated when the sled is cranking/on, this makes sure that high pressure propane isnt pushing on stuff when the sled is off. then to the regulator, it runs coolant throught it to make sure the engine is only seeing vapor propane. then I will connect a line that runs the propane vapor into the propane mixer(carb) I need to fabricate a adapter to go from the square bolt pattern to 2.5" pipe to connect to my throttle body, other then that, its pretty freakin simple, as far as boost referencing, there is a labeled balance port on the mixer and the regulator, you just hook a line between them and bam, its ready for boost. the nice thing about the propane carbs is that there are 2 knobs to adjust tuning, the idle one and the WOT one, which just dials from R<->L that being rich to lean, its stupid simeple, so should be damn easy to tune. I got most mounting locations already figured out, this weekend I will most likely get the regulter mounted and the lines for it plumed in. enough blabbing, heres a picture of the parts laying on the floor.

also, the ups man came today... GOT PROPANE!??? The system is stupid simple, and this is the fuel defivery system minus the tanks.

Line in from the tank throught a lockoff valve that is activated when the sled is cranking/on, this makes sure that high pressure propane isnt pushing on stuff when the sled is off. then to the regulator, it runs coolant throught it to make sure the engine is only seeing vapor propane. then I will connect a line that runs the propane vapor into the propane mixer(carb) I need to fabricate a adapter to go from the square bolt pattern to 2.5" pipe to connect to my throttle body, other then that, its pretty freakin simple, as far as boost referencing, there is a labeled balance port on the mixer and the regulator, you just hook a line between them and bam, its ready for boost. the nice thing about the propane carbs is that there are 2 knobs to adjust tuning, the idle one and the WOT one, which just dials from R<->L that being rich to lean, its stupid simeple, so should be damn easy to tune. I got most mounting locations already figured out, this weekend I will most likely get the regulter mounted and the lines for it plumed in. enough blabbing, heres a picture of the parts laying on the floor.