I think the well went dry over on the vipec site, but this question is more appropriate for this site

pro wire harness question

I have some kind of short

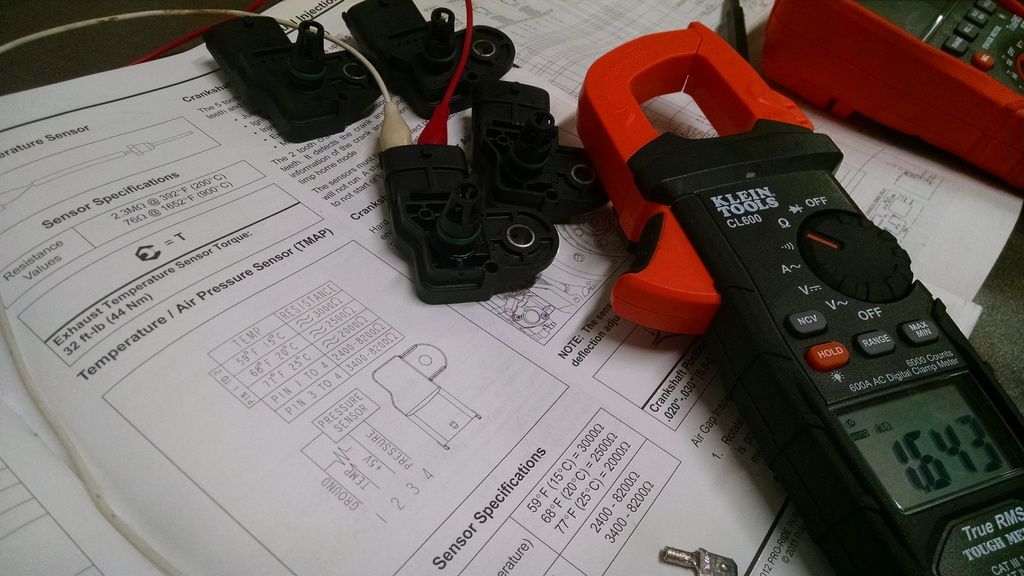

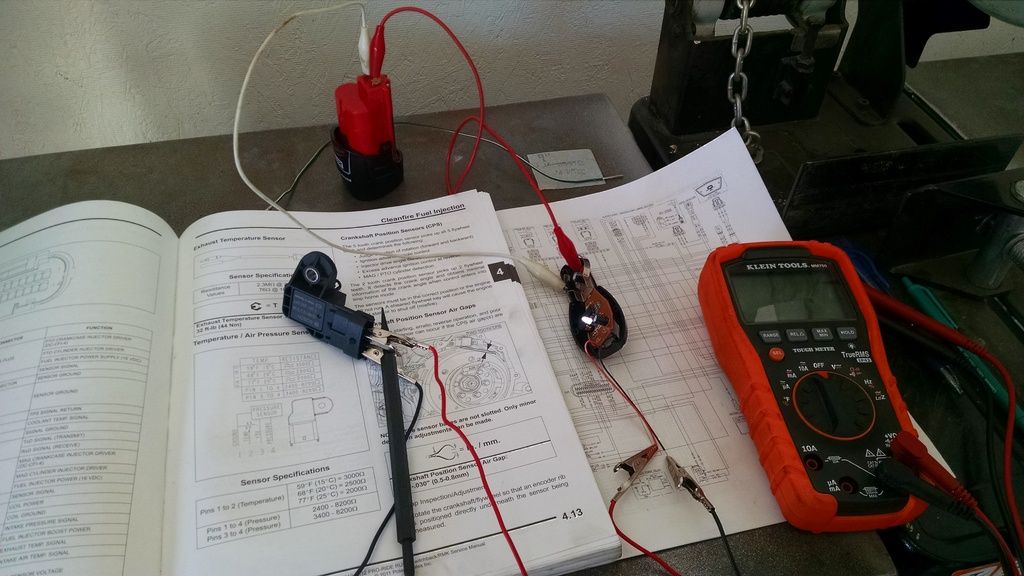

with a multi meter on the red/white and black/blue of the communication port, which is hooked directly to the 5v sensor red/white and the black/blue sensor ground, I read 2.3 millivolts. I can put pressure on the ecu connector and the sensors all start to work semi correctly and the meter will read 4.99v. without pressure on the connector I can then take the red test lead off the red/white and touch any other metal and read 4.30v. with pressure on the ecu plug I get 1.3millivolts everywhere.

I tried some di-electric grease with no change in connection

it dosnt look like I can crimp the terminals to make a tighter connection

I have the entire harness out and felt every wire for nicks in the jacket that might be shorting

I guess my question is what do those two pins in the communication port read on a stock machine with just the ecu powered by 12 volts

did an ohm check with the 12v hooked up and if I use my black test lead on the com port red/white or black/blue it beeps OL, but when I switch the test leads around I don't get any reading nor between the communication wires. without power I don't get a reading

pro wire harness question

I have some kind of short

with a multi meter on the red/white and black/blue of the communication port, which is hooked directly to the 5v sensor red/white and the black/blue sensor ground, I read 2.3 millivolts. I can put pressure on the ecu connector and the sensors all start to work semi correctly and the meter will read 4.99v. without pressure on the connector I can then take the red test lead off the red/white and touch any other metal and read 4.30v. with pressure on the ecu plug I get 1.3millivolts everywhere.

I tried some di-electric grease with no change in connection

it dosnt look like I can crimp the terminals to make a tighter connection

I have the entire harness out and felt every wire for nicks in the jacket that might be shorting

I guess my question is what do those two pins in the communication port read on a stock machine with just the ecu powered by 12 volts

did an ohm check with the 12v hooked up and if I use my black test lead on the com port red/white or black/blue it beeps OL, but when I switch the test leads around I don't get any reading nor between the communication wires. without power I don't get a reading

Last edited: