Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TPS Checker and Setting tool

- Thread starter 05900

- Start date

- Thread Rating

- 5.00 star(s)

Try this

http://web.archive.org/web/20030808092726/www.hardcoresledder.com/homemade_tps_tester.htm

Do you have the procedure for the 08 700's?

http://web.archive.org/web/20030808092726/www.hardcoresledder.com/homemade_tps_tester.htm

Have the procedure but no harness

Do you have the procedure for the 08 700's?

S

snoboy

Active member

I had trouble finding one and finally paid about $50 to the Pol dealer.

Me too.

The "plug" for the TPS is not available individually... The Polaris harness is the way to go, Unless you can find a junker with the plug/wires you can cut out.

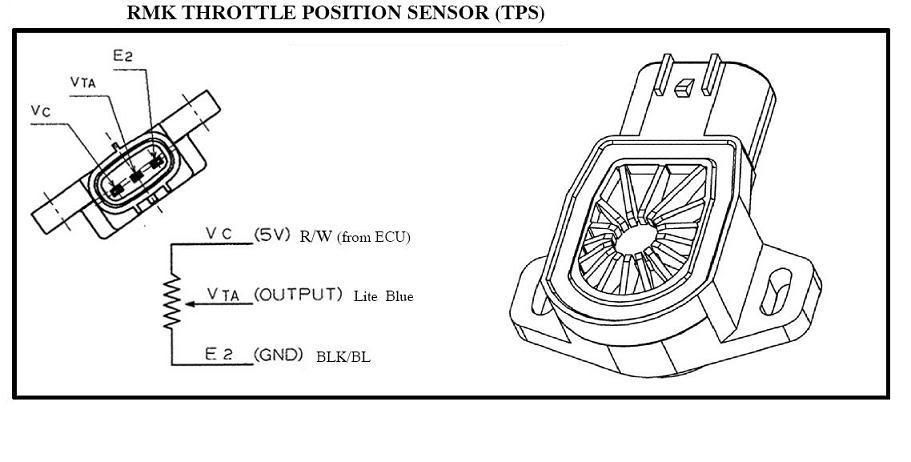

+5V to "Vc"

-5V to "E2" and to the (-) into your digital voltmeter

"Vta" is the output to the (+) on your voltmeter

Also, Remember this is not a TESTER....it is a tool for setting the TPS... you could have a "Bad spot" in the TPS and not have it show up on the meter..

To "TEST" the TPS, you need a good old fashioned analog volt/ohm meter, the kind with a needle and scale.

You hook the probes up to the Vc and Vta terminals and slowly squeeze the throttle lever... look for smooth movement of the needle on the meter without any jumping or dropping off the scale.

I had one TPS that "set well" but it had a dead-spot in it.

Also, The 5 volt regulators from Radioshack come as bad as well... Test for 4.99 to 5.01 volts, with a fresh 9 volt battery before you solder it together... I had 3 out of 5 test low for voltage from the ones I bought at radio shack.

TPS TESTER

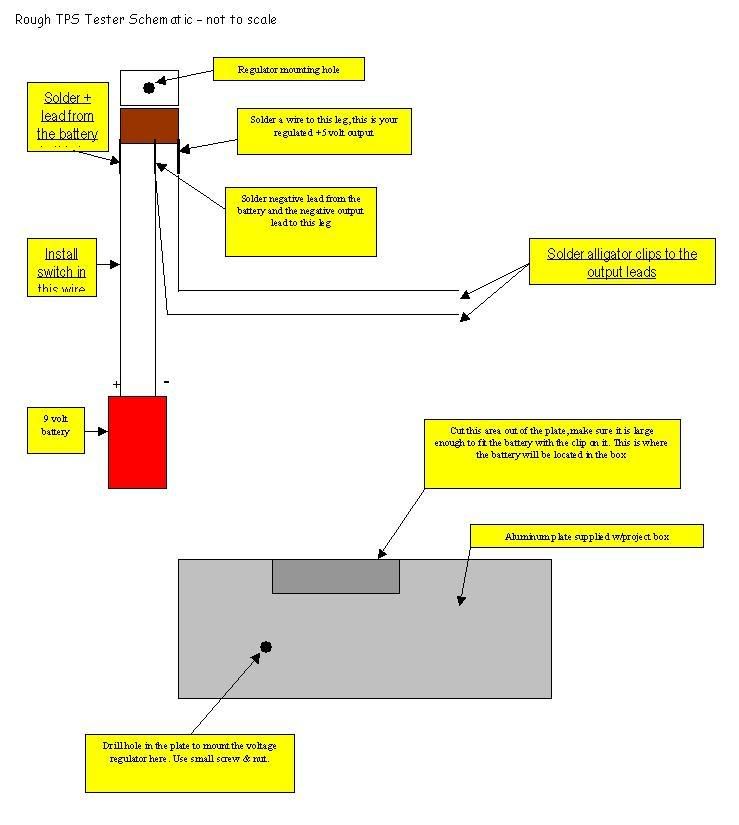

These are Radio Shack Parts numbers to assemble a homebuilt Polaris TPS tester.

2761770 - $1.49 +5VDC voltage regulator 1amp

2700324 - $1.99 9 volt battery connectors (they only come in a pkg. of 5)

2701545 - $2.99 Insulated Alligator Clips(come in a pkg. of 6 pairs)

2701802 - $2.29 Project Box

2300875 - $2.69 9 volt Battery

Total price for regulator, 1 battery connector, 1 pair alligator clips,

project box and battery was $7.36.

--------------------------------------------------------------------------------

On the CFI's you dont set it at WOT.... you set it at Idle...

The terminal is Vta, the center one.

The terminal is Vta, the center one.

TPS BASELINE RE--SETTING PROCEDURE

The TPS comes set from the factory and should not need any adjustments. If replacing a TPS or resetting the TPS, Polaris has

developed a TPS test kit for aid in setting the Throttle Position Sensor to specification.

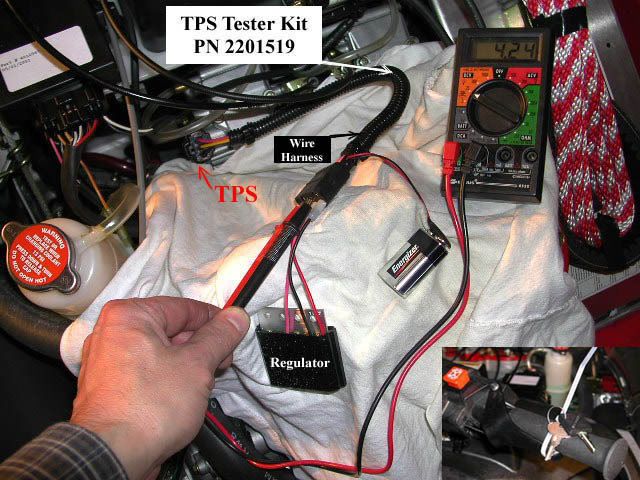

1. Assemble your TPS sensor tool (PN 2201519) as per the instructions that came with the tool.

2. Make sure your 9 volt battery is in good condition by inserting the black voltmeter probe from your Fluketmeter in the black

terminal and the red probe into the pink terminal. Voltage should read 4.99 to 5.01 volts. If not, try a new 9 volt battery.

3. Insert the red voltmeter lead into the terminal above the pink wire, and the black meter lead to the terminal above the black

wire. Slowly open throttle and check for smooth voltage change.

NOTE: The Fluke meter will change scales and show O.L. momentarily when throttle is opening.

4. Remove the throttle cable in order to take the slack out of the cable.

5. Back off the idle lock nut counterclockwise and then back out the idle adjuster (A) counterclockwise until the screw tip (B)

separates from the adjusted lever tab.

6. Turn the synchronization screw (C) counterclockwise until the synchronization lever is touching the synchronization screw

hole (D) tab.

7. Remove the connector from the TPS on the throttle body and install TPS sensor tool on to the TPS.

8. Place a shop towel under the throttle body incase you loose grip on the spring or thread a small wire around it if it should fall.

9. Remove the synchronization lever tab spring (E) and gently open and then close the throttle plateswith the throttle, allowing

the plate to close gently. Note the voltage at this point.

10. Insert the synchronization lever tab spring and screw.

11. Turn the synchronization screw clockwise until the volt meter reads the voltage level that you noted in step #8.

12. Loosen screws on the TPS sensor (F).

13. Adjust the TPS sensor until the voltage on the volt meter reads .705 -- .715 volts.

14. Tighten the TPS retaining screws, making sure that the voltage continues to read .705 -- .715 volts.

15. Turn the idle set screw clockwise until the voltage reads .930 volts.

16. Voltage at the yellow terminal should be .920 -- .940 volts at idle. Once the TPS voltage is verified and set, remove the sensor

tool and re--install the TPS harness

All you really need is a meter to set TPS......Do a search for my old posts for info.....

mhorse...

I made two tps tools this weekend. One was made from parts at radio shack. I had everything hooked up properly, checked the voltage from the 9V battery first to make sure it had good output but when i checked output of the tool it was only 4.96v rather than 4.99-5.01. I did read that some regulators are not up to spec as well as some batteries. I checked a few batteries with the same result. I also checked the output right from the regulator to see if the wires or aligator clips were causing power loss.

I then took an old cell phone charger that was 5v and attached alligator clips to the cut ends. When i checked the voltage it would only read 4.90.

My last thought is that my meter is not very accurate since it was kind of cheap.

Any thoughts? Should i try another regulator and a different meter?

I made two tps tools this weekend. One was made from parts at radio shack. I had everything hooked up properly, checked the voltage from the 9V battery first to make sure it had good output but when i checked output of the tool it was only 4.96v rather than 4.99-5.01. I did read that some regulators are not up to spec as well as some batteries. I checked a few batteries with the same result. I also checked the output right from the regulator to see if the wires or aligator clips were causing power loss.

I then took an old cell phone charger that was 5v and attached alligator clips to the cut ends. When i checked the voltage it would only read 4.90.

My last thought is that my meter is not very accurate since it was kind of cheap.

Any thoughts? Should i try another regulator and a different meter?

Battery supply voltage

I wouldn't be too concerned about being 30 millivolts on the low side if your using a lower quality meter/leads

I wouldn't be too concerned about being 30 millivolts on the low side if your using a lower quality meter/leads

R

Ron

ACCOUNT CLOSED

Carl's states that the only accurate way to set TPS is with the throttle plates closed, not at idle. Polaris gives a setting for idle but that is just an estimate since idle position of the throttle will vary.

This is one setting I would have done by the dealer. It's critical to sled performance and close isn't good enough.

This is one setting I would have done by the dealer. It's critical to sled performance and close isn't good enough.

Last edited:

Good info!! Thanks guys.

Baseline setting is what Carls is referring to (above in the description)

The baseline calibration IS with the throttle plates closed. This is an independent adjustment of both TB's.

THEN you adjust the TPS to the closed throttle plates at :

900/755 CFi .705 - .715 volts (I shoot for the middle at .710)

600/700/800 CFi 0.70 +/- 0.01 Vdc.

After the baseline is done... THEN you open the throttle plates with the Idle screw to:

2005 900 & 2006 900/755 CFi .930 volts

600/700 CFi .950 volts

2008/09/10 800 CFi .930 volts

All +/- .01 volts

... lock it down (I like to use low strength wick-n-lock locktite on this screw after it is locked down.

I just did one on last night with my home-made TPS tester... it took me about 10 minutes once I got to the TB's.

I've done this on many sleds... a lot of them new.... that were off by a long shot. Helped to clean up the throttle response on those that were off.

If you have a little patience, the factory tester (or the homade one) and a multimeter, this is one of the least inimidating processes on the sled... Just follow the video that I posted up.

ALSO as a side note... I had to go thru a couple of regulators at radio shack until I found a good 5.00 vdc regualtor... most were out of spec.

I made another tester for a friend and found that my local computer parts house had better quality reguators that were spot on.

I helped a guy locally last year that was having a real hard time with his new Dragon 700... The TPS sensor had some internal problems that would not show up in the baseline calibration it was more mid range... I put an old school analog meter on the output and found it had a dead spot internally that was causing the problem...this is hard to spot with a digital meter. I first do an idle to WOT (slowly) with an analog meter to verify that the TPS itself is good and shows a smooth voltage increase.. then I do the full baseline calibration... I had a spare TPS with me and got him up and running in the parking lot.

The TPS setting method for the CFi's is NOT the same as the carbed sleds and should not be used with the CFi motors.

Baseline setting is what Carls is referring to (above in the description)

The baseline calibration IS with the throttle plates closed. This is an independent adjustment of both TB's.

THEN you adjust the TPS to the closed throttle plates at :

900/755 CFi .705 - .715 volts (I shoot for the middle at .710)

600/700/800 CFi 0.70 +/- 0.01 Vdc.

After the baseline is done... THEN you open the throttle plates with the Idle screw to:

2005 900 & 2006 900/755 CFi .930 volts

600/700 CFi .950 volts

2008/09/10 800 CFi .930 volts

All +/- .01 volts

... lock it down (I like to use low strength wick-n-lock locktite on this screw after it is locked down.

I just did one on last night with my home-made TPS tester... it took me about 10 minutes once I got to the TB's.

I've done this on many sleds... a lot of them new.... that were off by a long shot. Helped to clean up the throttle response on those that were off.

If you have a little patience, the factory tester (or the homade one) and a multimeter, this is one of the least inimidating processes on the sled... Just follow the video that I posted up.

ALSO as a side note... I had to go thru a couple of regulators at radio shack until I found a good 5.00 vdc regualtor... most were out of spec.

I made another tester for a friend and found that my local computer parts house had better quality reguators that were spot on.

I helped a guy locally last year that was having a real hard time with his new Dragon 700... The TPS sensor had some internal problems that would not show up in the baseline calibration it was more mid range... I put an old school analog meter on the output and found it had a dead spot internally that was causing the problem...this is hard to spot with a digital meter. I first do an idle to WOT (slowly) with an analog meter to verify that the TPS itself is good and shows a smooth voltage increase.. then I do the full baseline calibration... I had a spare TPS with me and got him up and running in the parking lot.

The TPS setting method for the CFi's is NOT the same as the carbed sleds and should not be used with the CFi motors.

Baseline setting is what Carls is referring to (above in the description)

Last edited:

Just for info.....what are some signs that a TPS is not properly set or bad ??

The manual says 0.700 +- 0.01 volt.

0.94 at idle +- 0.01 volt

i set mine at carls spec also...They seem to know alot.

The new -09 are all over the scale...unfortunatly...

At our testing we have also found alot of improvments ....

Think of it this way if you apply throttle of 55% and the ecu

thinks youre at 63% throttle- wrong timing and wrong a/f ratio..

And one symptom of wrong tps is low idle and the engine stops

when going into reverse.....And the infamous booooooooogggg

ED

Last edited:

R

Ron

ACCOUNT CLOSED

MH,

There must be some changes from the 900's. The 09 Service Manual gives baseline settings that are also different for CFI 6/7's (.95 +/-1)& 8's (.93 +/-1). My manual says to reset the baseline and idle if you move or change the TPS. Same numbers as posted by IQ in above post for BL & Idle.

If the TPS is correct is there any reason to complete the other two steps?

There must be some changes from the 900's. The 09 Service Manual gives baseline settings that are also different for CFI 6/7's (.95 +/-1)& 8's (.93 +/-1). My manual says to reset the baseline and idle if you move or change the TPS. Same numbers as posted by IQ in above post for BL & Idle.

If the TPS is correct is there any reason to complete the other two steps?

Last edited:

Similar threads

C

- Replies

- 1

- Views

- 198

E

- Replies

- 0

- Views

- 789

- Featured

- Replies

- 29

- Views

- 2K