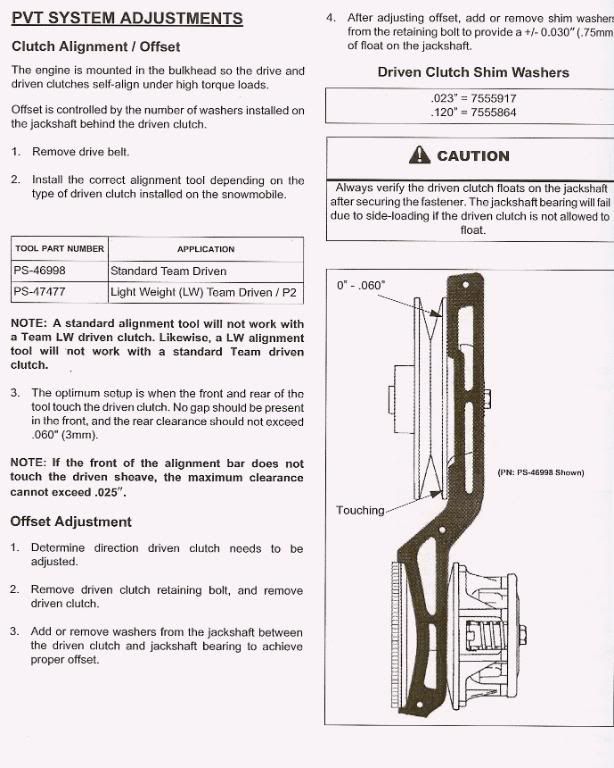

OK try to figure this out.....I bought a team aftermarket tool from fastrax part #930716 which is for the newer team secondary and is suppose to work on my 08 RMK 600 that calls for the same belt 115. Destuctions say hold the bar on the outer (fixed) portion of the secondary with the secondary pushed in tight against shims and the JOG (Offset of the bar) should either JUST contact the inner part of the primary fixed clutch face or have no more than .030 clearance. Great; Then to check Parallelism there is a x on the back side of the jog and a Y on the forward part of the jog that you should measure to the same point of the primary inner outer edge(widest part of fixed primary sheave) and compare these figures. They should be equal or y must not exceed x by more than .060. This is to compensate for engine torque.

Well I then went to work (BIG MISTAKE) trying to check this tool and figured if you take the thickness of the outer edge of the sheave the bar sits on to the belt, Plus the width of the belt, Minus the taper of the belt (1/2), it SHOULD add up to the offset of the tool right???

NOPE--- so someone please help me make sence of this

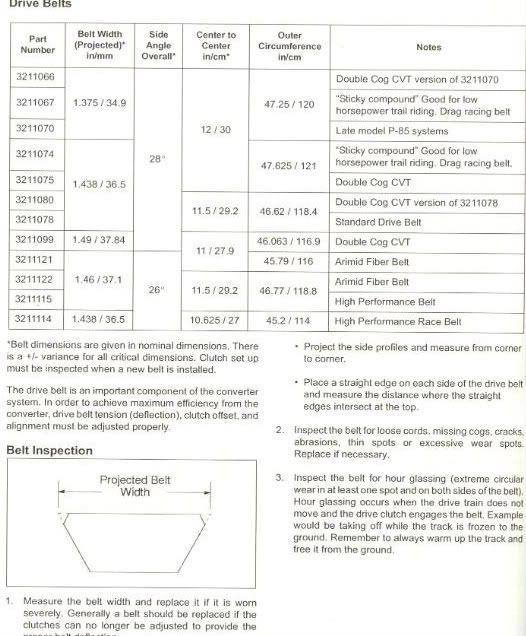

Here's my figures ;Thickness of secondary sheave to belt-.190 ,PLUS thickness of belt Mine are 1.44-1.45, Book says 1.46 so we will use that, MINUS thickness of taper on half the belt to get to where offset tool is measuring to, I came up with .155 (outside width - inner taper width devided by 2, plus .010 for half of the .020 belt clearance i have set into the primary,EQUALS---1.505 Well my Tool measures 1.340 offset (as always my tool is tooo short) Soo what am I missing other than snow????

A spokane dealership was kind enough to measure there tool offset and and there's came up to 1.7?? so don't know if they were measuring the same spot or not so was going to order another one and asked what they came up with and it was the pn I have....Go Figure

ALSO to throw another wrench in the mix Western power sports show a differant tool for electic start but nothing should change from where I am measuring from on either model so HELP