pull back up the old thread if you want to keep going with it, back to topic

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I'm not a push turbo guy- but very cool

- Thread starter av8er

- Start date

K

knifedge

Well-known member

http://www.pushturbo.com/PRO-800.html

Yes, the Push setup is available with or without a Tial setup. Plenty of good selection of turbo kits with or without Tial exhaust.

Yes, the Push setup is available with or without a Tial setup. Plenty of good selection of turbo kits with or without Tial exhaust.

S

sweperformance

Member

Some throttle body before turbo references!

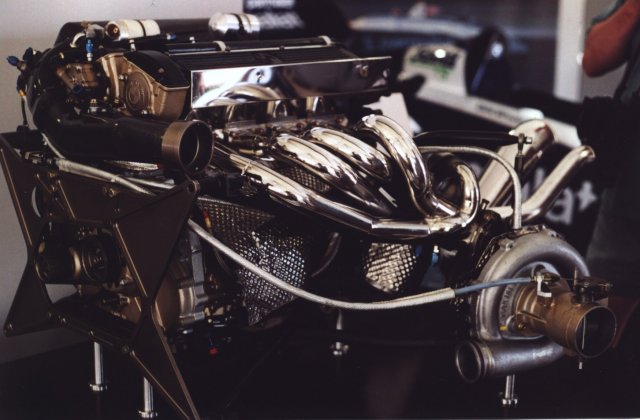

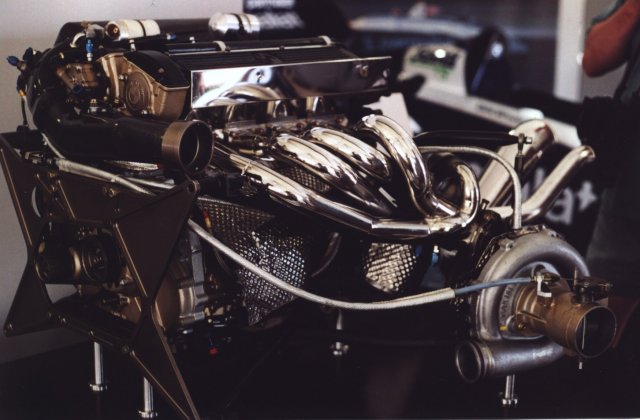

Renault 1.5 V6T, F1.

BMW F1 Turbo engine.

So I hope that no further doubt for this system exists .

.

Renault 1.5 V6T, F1.

BMW F1 Turbo engine.

So I hope that no further doubt for this system exists

S

sunbather1969

Well-known member

So you have nothing

And decided to bring everyone else down !

www.pushturbo.net new web page- very cool information on new turbo kits

the future is looking bright, assuming boondocker, twisted, and cutler can develop stand alone kits also no more damn fuel boxes to monkey with.

And decided to bring everyone else down !

M

mynewuseddoo

Well-known member

Swe, good find. I went to the same websites that you pulled those pics from. A lot of discussion about this system. Many of the TBBT setups are actually running two sets of throttle bodies, 1 before turbo and one at the intake manifold. They had problems with the suction created by the engine that was causing the compressor seal to leak oil. They needed special oil seals to eliminate this or run two sets of throttle bodies. I'm wondering if this will be the case with push's single TBBT setup. Is there enough suction created by the 800cc 2 stroke engine to cause failure of the compressor oil seal prematurely? Having that TBBT slam shut at 8000 rpm has got to be pulling pretty good while the engine winds down. Time will tell I guess.

S

sweperformance

Member

Is this problem specific to the oil bearing turbos maybe? Should not be a problem on ball bearing turbos?

Swe, good find. I went to the same websites that you pulled those pics from. A lot of discussion about this system. Many of the TBBT setups are actually running two sets of throttle bodies, 1 before turbo and one at the intake manifold. They had problems with the suction created by the engine that was causing the compressor seal to leak oil. They needed special oil seals to eliminate this or run two sets of throttle bodies. I'm wondering if this will be the case with push's single TBBT setup. Is there enough suction created by the 800cc 2 stroke engine to cause failure of the compressor oil seal prematurely? Having that TBBT slam shut at 8000 rpm has got to be pulling pretty good while the engine winds down. Time will tell I guess.

This is what I was wondering about 2 pages ago, The only thing is that if you are running 8lbs of boost and slam shut the TBBT there is still 8lbs in the intake and would take a few sec to burn off, or something like that, lots of intake pressure and boost pressure going both ways, it may not be enough to matter. There will be some trial and error with this system, can't wait to see how it turns out, it could be the next real deal. But until proven its just another prototype and I don't want to be the one that finds out if it doesn't.

G

Going West

Well-known member

I emailed ken at push and was told that the Race gas kits will come with a 28-71 with a hta billet wheel. Supposed to flow more then the the 28-76 and spool way faster.

Also stated that the race gas customers will have full accesss to the ecu. Race gas setup is only $150 upgrade.

Ken also said that they have field tested the TBBT last season, Its just the electronics that have not been tested with his turbo setup, they have been run on different setups in europe. They are beging dyno testing next week and field tests as soon as snow is availble.

Also stated that the race gas customers will have full accesss to the ecu. Race gas setup is only $150 upgrade.

Ken also said that they have field tested the TBBT last season, Its just the electronics that have not been tested with his turbo setup, they have been run on different setups in europe. They are beging dyno testing next week and field tests as soon as snow is availble.

V

Vi-PEC Powersports

Well-known member

éééI emailed ken at push and was told that the Race gas kits will come with a 28-71 with a hta billet wheel. Supposed to flow more then the the 28-76 and spool way faster.

Also stated that the race gas customers will have full accesss to the ecu. Race gas setup is only $150 upgrade.

Ken also said that they have field tested the TBBT last season, Its just the electronics that have not been tested with his turbo setup,

they have been run on different setups in europe.

That is absolutely not true......no need to lie to sell those standalone ecu for ken.....i'm probably the guy that have spoke to Brani the most in last 6 months( almost every day) and i know for a fact that his ecus are totaly new to the market and have not been tested other than idleing sleds.This being said, we are going to tryout and be a dealer in eastern part of Canada for Branix (for AC sleds) if the prototype ecus are what they are suppose to be and will soon find out.Brani is for sure knowledgable and very serious about business......time will tell if his ecus are all that....just my .02

They are beging dyno testing next week and field tests as soon as snow is availble.

Last edited:

Did Branix have an ecu out last year for the Ski Doo? How did it work? I haven't heard anything on it since last season.

G

Going West

Well-known member

I dont know who you think is lieing, maybe you.

I couldnt find the post I wanted where sleds were the topic but this is a quote from brandix about AC quads and his ECU, Its the same basic unit as for the sleds.

"I am the designer of the ECU for Arctic cat 951cc engine

Personally i own a 2011 mud pro, and i run it actually for 7000 miles with our own ecu. the ECU exist for 2,5 years now and i think we have now over 100 customers using them on 2009 and 2011 951cc Cat.

the 2011 ecu is now only working on my private mud pro. "

Maybe use some though before you start calling people out

I couldnt find the post I wanted where sleds were the topic but this is a quote from brandix about AC quads and his ECU, Its the same basic unit as for the sleds.

"I am the designer of the ECU for Arctic cat 951cc engine

Personally i own a 2011 mud pro, and i run it actually for 7000 miles with our own ecu. the ECU exist for 2,5 years now and i think we have now over 100 customers using them on 2009 and 2011 951cc Cat.

the 2011 ecu is now only working on my private mud pro. "

Maybe use some though before you start calling people out

I dont know who you think is lieing, maybe you.

Who are you talking about?

G

Going West

Well-known member

I dont know who you think is lieing, maybe you.

Who are you talking about?

Two posts up where Precision E.F.I calls me a liar for simply passing on some info that I had received.

Sorry for the confusion.

V

Vi-PEC Powersports

Well-known member

Two posts up where Precision E.F.I calls me a liar for simply passing on some info that I had received.

Sorry for the confusion.

Sorry for the confusion on my side also.....i am not calling you a liar, i am simply telling the retailer does not need to lie on the ecu to sell it. It is nothing about you going West . Like i said earlier, the ecu is totaly new to the market and the design of the actual pcb board with all chips is completely new......a lot of people have already installed on their sled standalone ecu in NA and Europe and everywhere!!!Branix design is based on some ecus that were already running BUT his powersport ecus are totaly new design.Of course Branix is throwing out an excellent product i am sure(even me i have not seen anything yet) because his company is focusing on the powersports market and i am sure he doesn't want to go bankrupt!!!

again sorry for the confusion

P

polemite.productions

Well-known member

i can't read any of the conversation beyond the halfway point on page 2, but in any case- going back to my skepticism about the turbo staying spooled when choking off the inlet (pg 1), i got to thinking about how i could test the theory while at work today. i remembered that we have a welding exhaust fan over one of the benches in the shop, and it is just a centrifugal blower driven by a 600v motor with a long tube attached to the inlet that you can pull around with you wherever you are working.

the motor turns at 1800 rpm. that is a constant, or close enough to one, regardless of how loaded or unloaded the blower is. so the test was to choke off the inlet and measure current (load) with my amp meter to find out if the motor had to work more or less as the inlet was restricted.

i tried unrestricted, 1/3 blocked, 1/2 blocked, and fully blocked. there is no doubt, the more that the inlet was blocked off, the less current the motor pulled. there was still the load of the resistance of the bearings, and the weight of the impeller, but the lack of air resulted in a fan that turned more easily. i'm not skeptical about that part at all now.

the motor turns at 1800 rpm. that is a constant, or close enough to one, regardless of how loaded or unloaded the blower is. so the test was to choke off the inlet and measure current (load) with my amp meter to find out if the motor had to work more or less as the inlet was restricted.

i tried unrestricted, 1/3 blocked, 1/2 blocked, and fully blocked. there is no doubt, the more that the inlet was blocked off, the less current the motor pulled. there was still the load of the resistance of the bearings, and the weight of the impeller, but the lack of air resulted in a fan that turned more easily. i'm not skeptical about that part at all now.

No different than when a boat has cavitation the rpm go up, but its that initial shut off that pulls against everything once shut it creates a void and doesn't really pull on anything, but usually it increases heat.

S

sweperformance

Member

Same thing with the vakuum cleaner at home. When you block the hose, the rpm in the motor goes up/current goes down.

S

sweperformance

Member

That about the IC injection system? Is it alcohol injection or just adding fuel/air for cooling?

That about the IC injection system? Is it alcohol injection or just adding fuel/air for cooling?

Its just a second set of injectors injecting fuel into the charge pipe.

Similar threads

- Replies

- 0

- Views

- 725

H

- Replies

- 22

- Views

- 4K