Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Watercraft thread

- Thread starter 4Z

- Start date

- Thread Rating

- 5.00 star(s)

The new metal gasketts are not ribbed but flat,they are using them on the910 as well.

Brad did i understand that yoiu are putting new hubs in the fly wheels instead of retapering?

I just wanna know if the metal gaskets will seal the thin spot on the cases or get the paper ones? Brad said that he has never had a problem using the 1211 sealant but im assuming this was with the paper gaskets?

As for the hubs, yes it is a new billet piece re-riveted into the flywheel, totally bolt up and go! You get alot more contact with the keyway so it wont sheer off like some did in the past.

Ya the new hub is pretty slick. I updated mine and the fit and finish is perfect. Brad also has the new mag housing that bolts directly to the case, no mag end machining on the case anymore, I think it uses 7 bolts and a dowl vs 4 on the old one, much stronger.

Are you running the new mag housing or just do the new hub? I put one on my motor and it fits like a glove! No more machining the case end flat, totally bolt on deal plus the extra mouning bolts should keep it in place and not rattle loose like the old setups!

The metal ones are much less likely to leak or "blow out". I'm using them on the 770 I built (800 cylinders on a 700 twin case) and haven't had any issues around the water passage in the front of the cylinder. I do use a layer of 3-Bond around the water passages though.

polaris can keep those metal gaskets, I think they are junk. if you dont have the full width gasket area, the metal ones are going to leak, its just a matter of time. and if you think you dont have to weld and redeck for the 1200, it will cost you a crank at the least when it does finally go, and it will. Just ask anyone that owns a struthers 910, same problem, and he denies it too. but I've seen 2 do in my area. its not worth the troubles. have it welded before you have it fly cut, then deck it.

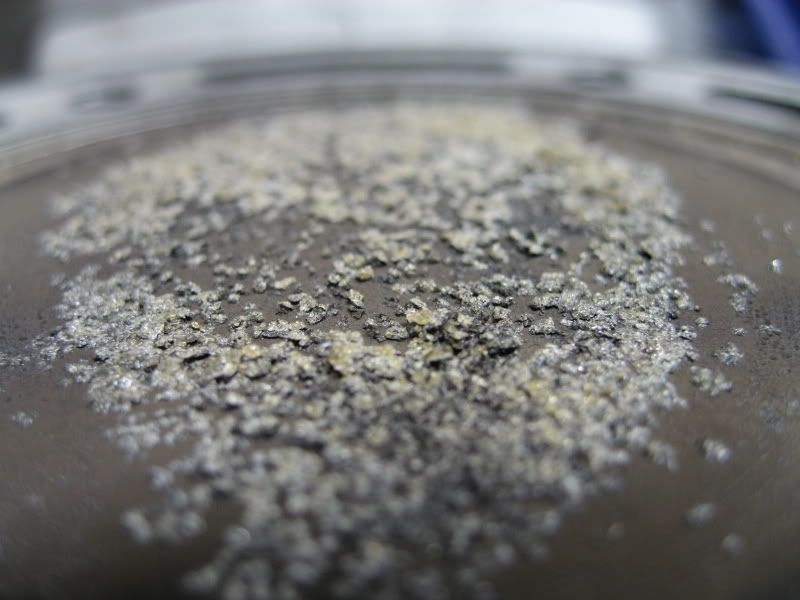

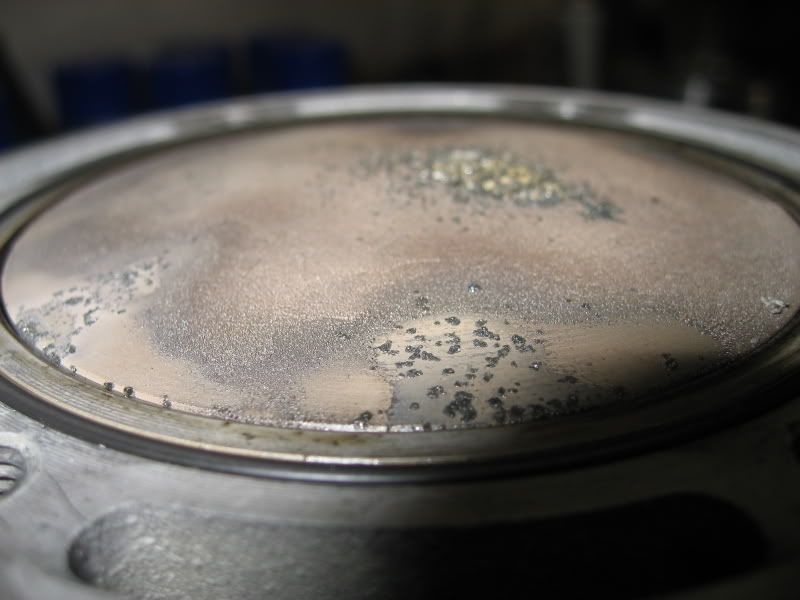

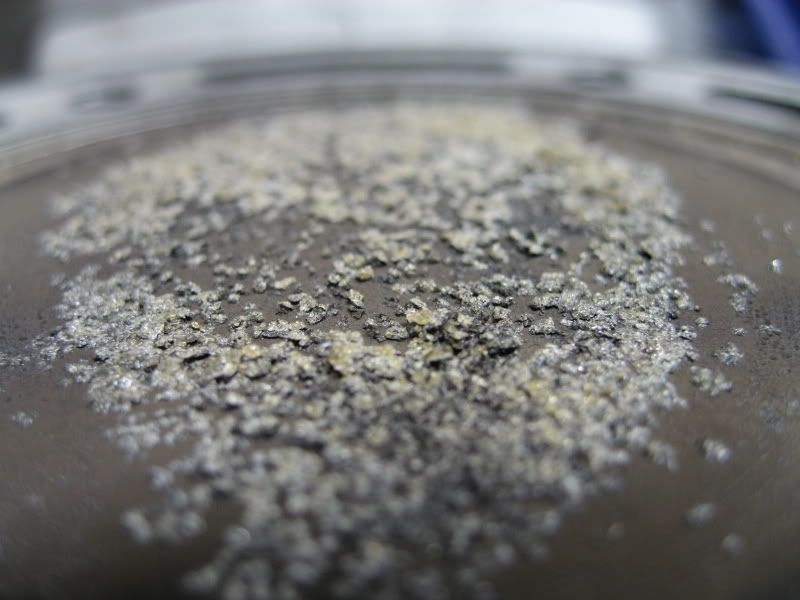

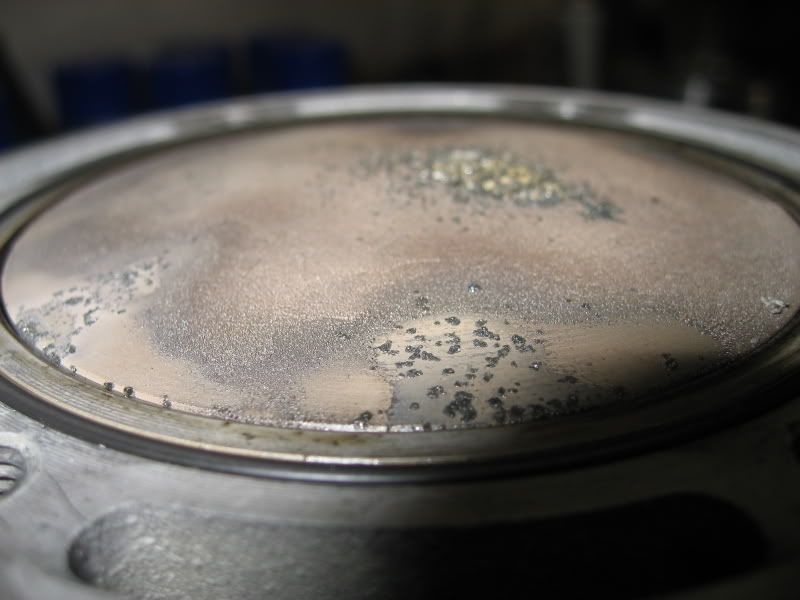

this is what it will look like

this is what it will look like

Last edited:

jim are you sure thats from antifreeze it looks more like crystal meth . LOL

Brad

i agree paper and 1211 is the only way never a problem.

Brad, explain to me how you know what crystal meth looks like........

On a fly cut cyl that has not had the welding done, I have had metal gaskets leak internaly unless I put a generous amount of Right Stuff by Permatex on it. That stuff is better for coolant than 1211. Otherwise 1211 work excellent for fuel contact areas.

Regarding the flywheel hubs. I recomend anyone with a lathe tapered flywheel to send it to Brad for the billet hub. This is well worth the money. I have already started converting motors. I would still like to kick Brad in the thin skin someday for not building the housing and hubs sooner............

Last edited:

crystal something. that was r8n's motor after a few rides.. I also wonder how much extra clearance is needed for the cylinderskirt + spacing?

Brad, didnt you say that you dont build up the waterjacket area and have had excellent luck with the 1211?

Didnt UBR build a small spacer plate for their larger cyls on the WC bottom end? If so you still need to flycut the cases and you have one side of the plate in contact of the CC and waterjacket having this same issue? I know they would weld it up though.

Didnt UBR build a small spacer plate for their larger cyls on the WC bottom end? If so you still need to flycut the cases and you have one side of the plate in contact of the CC and waterjacket having this same issue? I know they would weld it up though.

S

schu

New member

I have archived the old thread at http://sledresource.com so it won't be lost. I also archived some other interesting threads. If anyone as any other technical threads they wished saved please contact me soon.

schu

schu

I know lynn ran a fairly big hit of no2, are you running a homebuilt kit using NOS parts? I was thinking about setting up a small hit of it on mine when I get it done.

Could all you WC guys list your setups and elevation so Ill have a better start of a baseline setting for clutching and jetting?

1200 VES, CS pipes, 13.5:1, VF reeds, 38 mill rackslides (t-cat), 144x1.5" cutdown, holz prox chassis, P85 primary, cat secondary.

Could all you WC guys list your setups and elevation so Ill have a better start of a baseline setting for clutching and jetting?

1200 VES, CS pipes, 13.5:1, VF reeds, 38 mill rackslides (t-cat), 144x1.5" cutdown, holz prox chassis, P85 primary, cat secondary.

S

Snowstar

Well-known member

Yep just a NOS wet kit pieced together, this thing just rips, scary fast I would list my setup but im still working on a good combination. So far its 68 gram weights, 140-340 primary and 59-52 helix with some unknown red/white spring on a cat button driven clutch. Riding at 8-10k ft. turns about 83-8400 rpms.

I would list my setup but im still working on a good combination. So far its 68 gram weights, 140-340 primary and 59-52 helix with some unknown red/white spring on a cat button driven clutch. Riding at 8-10k ft. turns about 83-8400 rpms.

Similar threads

- Replies

- 29

- Views

- 3K

- Replies

- 0

- Views

- 1K

- Replies

- 11

- Views

- 2K

- Replies

- 0

- Views

- 2K