Av is fine to store... Metal cans are the best... The only issue I had was it would kill the afr sensor every 40 hours or so

.

Sent from my Pixel 2 XL using Tapatalk

Is that because of the lead in the gas?

afr - you mean the exhaust 02 sensor right?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Av is fine to store... Metal cans are the best... The only issue I had was it would kill the afr sensor every 40 hours or so

.

Sent from my Pixel 2 XL using Tapatalk

.. The only issue I had was it would kill the afr sensor every 40 hours or so

your post says you have a 2012 120 kit, if its stock , the keyway shafts will not take the power of your turbo, very short life for sprockets and shafts. You need to upgrade to splined shafts or later model kit with.

Just take it to an auto parts store it is a common Bosch part..

The jackshaft sprocket and shaft appear to be pretty messed up, along with the bearings. So replacing all that with parts from a local industrial supply shop.

I have the double bearing upgrade, and Im replacing the shaft with a 1'' keyed shaft and proper bearings. The shaft is pretty worn, so cant get an exact measurement, but from what I could figure it appears to have bean a 25mm shaft that timbersled used. Can anyone verify that?

Does anyone have answers to the post above this one?

Are 02 sensors generic and all that matters is the thread size?

Uses stock fuel pump?

Yes the stock fuel pump would work. I would run a twin air fuel tank filter. While you have it apart take the stock injector out of the throttle body and make sure it is clean.

Stock stator will work fine, just put your light on a switch and only use it when needed. The bike will be hard starting if the light is on during start up.

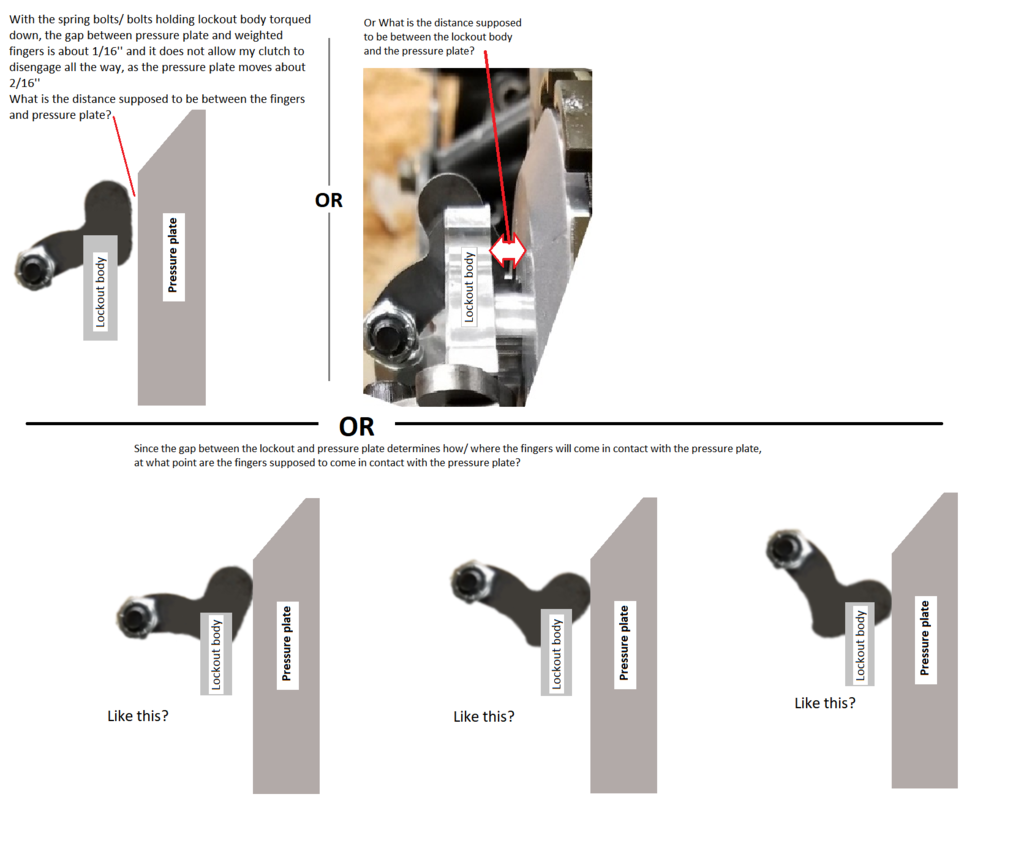

Looks like your lockout is installed correctly, You will just need to set the cable free play. You may need to use the secondary adjustor to get it within range.

In regards to the older shafts and sprockets.

TS kits use a 25 mm shaft just under an 1", so no replacements out there in general machine use, I have machined down 1" shafts and tried to outsource them, all a waste of time.

I wouldn't sweat getting the shafts and sprockets changed out as a first order of business, get your turbo running first. BUT for sure a FYI you need to be aware of.

. Originally TS had a kit and reasonably priced to convert to the newer splined shafts.

The only cost effective conversion now is to simply get with a TS parts person and buy the parts.

If you can only buy the driven shaft and not an assembly, not sure what Polaris is offering there, just buy the shaft and press your old sprockets on.

The brake disc is kind of a miserable situation if you try to replace it all. You really don't need to do that, but you will have to have a machine shop mill the key way for your disc brake ( so little stress on this keyway/key down one of the female spline grooves and with the old key you will never have a problem) . If you get to that situation, just pm me or and we can talk about that. You will have to make several spacers to complete the project, TS doesn't have all the correct parts, but if you are launching into a turbo project, a spacer better be very elementary.

I have converted a half dozen or so kits, from the first year on up, way better, quieter/safer/less maintenance, been a couple of years but about $400.

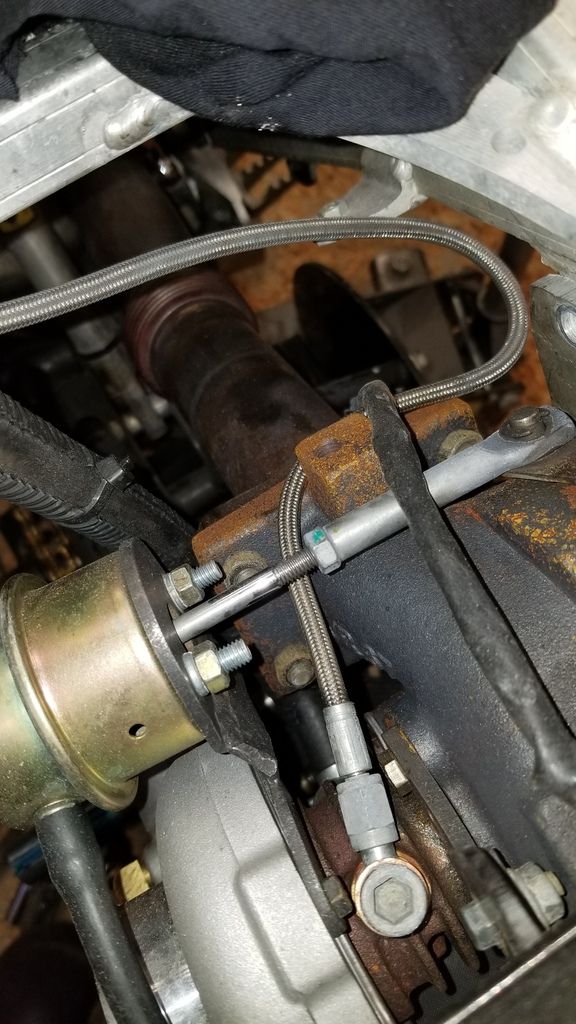

Loosen the jam nut, take off the clip and pop the rod off the post. Shortening the rod will raise boost, lengthening it will lower.