He posted the basic process on page 1 or 2 of this post.

Heres the entire process that I follow on my '12. Not sure if wiring is different on the 13-15, as far as pin location on the ecu plug etc...

1. Unkook throttle cable from thumb lever

2. Fully charged 12v battery

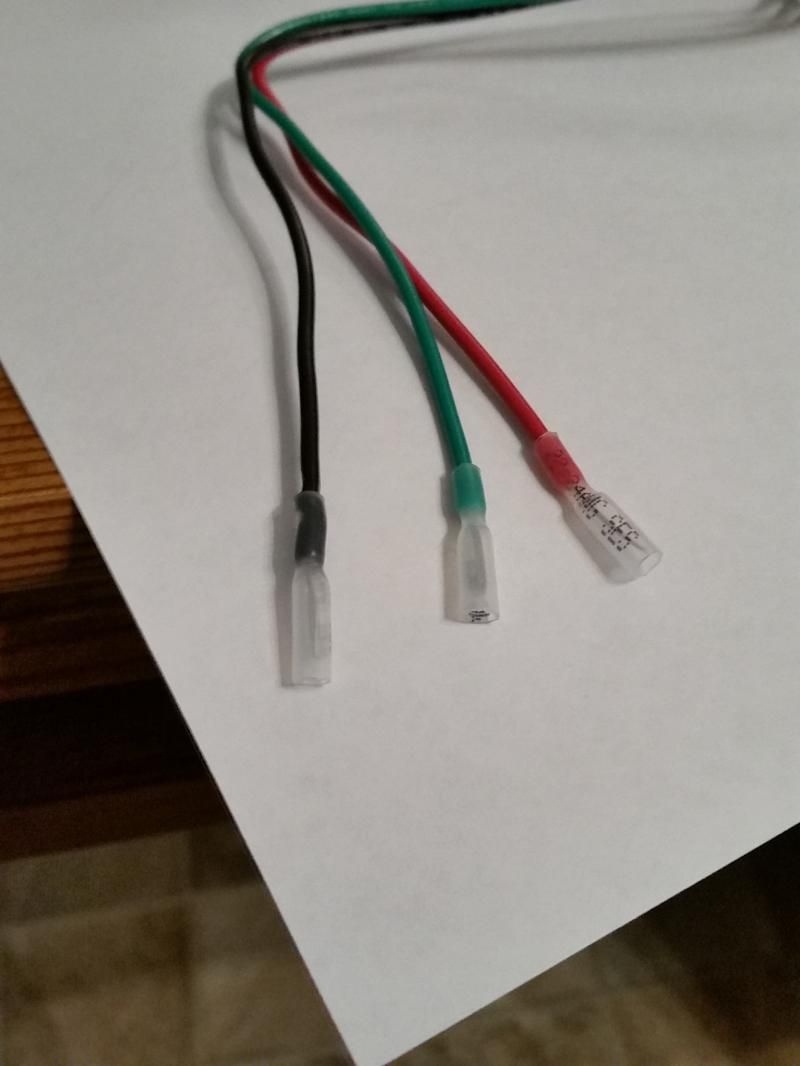

3. + to Orange wire, - to brown wire (on ecu power up plug, located above primary clutch)

4. Test red with white stripe wire for 5.0v reference voltage. I test mine at an 4 pin plug, that us unused, and hangs just above my mag cylinder. Should be dang near 5.0v dead nuts. Mine reads 5.01v

5. Use high quality multi-meter for this! Most of us prefer Fluke. Ive had same results with a Fluke 73, Fluke 88, and an unknown Blue Point i have.

6. Back probe pin #7 on the smaller ecu plug. In a bind i use a paperclip that i hammer and sharpen one end into a sharp fine point. Slide this in carefully, youre looking to make contact with the wire coupler. And youre testing for voltage output from that contact. This voltage should change as you move throttle linkage. Check it, make sure you have a good contact.

7. At this point, you should see voltage around .940v range (ideally). Thats your "idle voltage". .930-.950 is the rec spec i believe.

8. Locate the idle adjustment bolt. It is an internal allen head screw, with a 8mm lock nut. Located on the mag side of throttle bodies. Back this off til its not pushing the throttle linkage at all. Rotate throttle a couple times, and release it, allowing throttle linkage to fully close on its own.

9. Check voltage at pin #7 again. This is your BASE setting, and should be between .690-.710v (i believe thats spec)

10. That base setting is the CRITICAL part!! Adjust actual TPS as needed to achieve that. (Phillips locking screws on TPS, on far pto side of throttle body assemb.).

11. Pull, release throttle linkage again, allow to return, triple check this base setting!

12. Use idle adjust screw to open the throttle linkage until the voltage now reads the .930-.950 idle spec. Lock in place, and double check!

13. Reassemble, check operation, and punish sled on snow!

I think thats it, did i miss anything anyone? I will double check those voltage specs, and edit, or repost.

This, all assuming the TPS itself, is 100% and not screwed up. That requires another test, with a good analog meter for checking potentiometer function. Which should also be done! Tonkas tool works great for both of these, or you can test straight on the TPS, or backprobe the ecu.