P

PalousePoo

Well-known member

Ron, I'm still waiting for you to send me the purchase agreement where I buy your 09 D8, slightly used, in excellent cond, in October 09 for $8000.00. (with all goodies)

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

RON..

great info, thank you for taking the time to do that..much appreciated..

as i just mentioned in my other post, i asked my dealer to balance my wifes 06 700 clutch since i am replacing the spring and he told me there is NO reason to balance the clutch since it was done already by the factory when it was build...????????

i have ALWAYS trusted the main mechanic there at polaris, he is a great guy and knows his stuff, but then he said this and blew my mind..then he also said FNI intakes are garbage..yeh whatever..HA!!

Ron, In reassembling my secondary, There is NO wide spline on the shaft that the roller unit slides onto. In fact, I can slide it on in any position. The roller unit has the wide spline. What do you make of this? A mistake in production? I'll get back to you later on that "sales agreement" on your 09. It looks like my lawyer will be in touch

Great info, Ron.

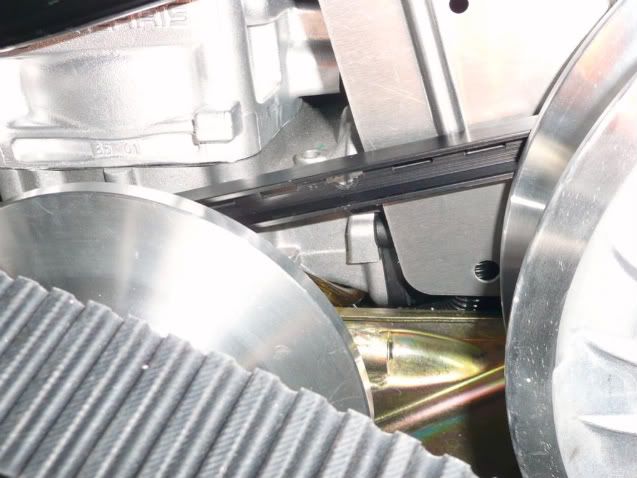

How do you recommend adjusting the motor twist? On my D7 it measures about 1/4" difference from the front of the secondary to the back. I posted a question on this a while back and was told to slot the motor mounts since there is no adjustment with the factory setup. Any particular way to go about this? I'm scaredof screwing things up.

Thanks!

Please explain! Moving the motor won't affect the secondary.

Or are you saying you have 11 3/4" clutch center distance instead of 11.5"? It's easy to be off a little getting that measurement but if you are certain I would take it to the dealer and let them fix it under warranty. Slotting the motor mounts means pulling the engine-to do that there are some technical things involved.

I think Ron he means he has a 1/4 in. twist in the motor that shows on the secondary as the alignment bar up tight on the front of the secondary and a 1/4 in off in the back...

I think Ron he means he has a 1/4 in. twist in the motor that shows on the secondary as the alignment bar up tight on the front of the secondary and a 1/4 in off in the back...

Yeah, that's what I meant. Sorry for not being clear. I've got the SLP alignment tool, and the instructions don't say anything about sucking the engine back against the torque stop. (???) According to SLP-- http://www.startinglineproducts.com/instsheets/20-191.pdf , the distance from the bar to the outboard edge of the secondary should be 0.40" greater at the rear of the secondary than it is at the front. Mine is around 0.250" difference, way too much. I don't know, maybe I should just forget about it and ride, but I would really like to have it right.