thanks ron and dan this i great info one question how would you go about getting the weights the same weight (where do you take the material from) also in your experiance do some of the a/m weights have better true weight #s the polaris weights i got have a few grams between them thanks

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Polaris P85 Drive Clutch Service/Setup/BluePrinting

- Thread starter Ron

- Start date

R

Ron

ACCOUNT CLOSED

thanks ron and dan this i great info one question how would you go about getting the weights the same weight (where do you take the material from) also in your experiance do some of the a/m weights have better true weight #s the polaris weights i got have a few grams between them thanks

There are two ways to do it-add weight or take it off. You can add to the back of the weight with a wire feed.

The 10 series usually run about a gram over, say a 62 is really 63. I normally adjust weight mid to base since that is where most of the mass is located. It's really a judgement call but if you look at the weight & try to add or remove uniformly in relation to the amount of mass seems to work best. If you have a weight out more than a gram it's out of spec. Poo says + or - one gram. If you have a good dealer (& new weights) take your gram scale in & see if they will let you swap some around til you get a set that is close. If your weights are used and out 2 grams you might add to the light one and take some off the heavy one.

The EPI weights I ran last year were "dead on" both to the correct weight & all 3 weighed exactly the same.

Comment on ????'s

I understand Ron.

back when there were not such massive size twins with huge low end torque, great fitting drive clutches and prefect tapers lended themselves

to hold ok even with sum type of lube in thinking it would allow for better removal. And it did becuase the amount of surfaces area that was locked up hard was less due to the oil. the low torque motors did not seem to tear up the tapers to bad they hooked up enough to hold most of the time.

shimming weights is a bit of a feel thing. shim them as tight as you can without causing a binde of any kind. the big concern here of shimming weights to any degree.

keep in mind that if the weight has some room to move it will find its happy float area once the clutch spins.

if you shim a weight to a very control area you are at the mercey of that area of the clutch being at a tru 120 degrees. Remember you are pushing around alot of weight and you can hurt the balance ALOT . Always make sure the weight is tracking as close to dead center in the spider roller as you can get it.

Next post may surprise some of you.

Dan

Thanks for the info Dan, I'm "one of those" that has put a light coat of grease on the crank & wiped it off leaving a film. Will try the dry application, makes sense, if the clutch seats on the crank there is no room for moisture.

I understand Ron.

back when there were not such massive size twins with huge low end torque, great fitting drive clutches and prefect tapers lended themselves

to hold ok even with sum type of lube in thinking it would allow for better removal. And it did becuase the amount of surfaces area that was locked up hard was less due to the oil. the low torque motors did not seem to tear up the tapers to bad they hooked up enough to hold most of the time.

shimming weights is a bit of a feel thing. shim them as tight as you can without causing a binde of any kind. the big concern here of shimming weights to any degree.

keep in mind that if the weight has some room to move it will find its happy float area once the clutch spins.

if you shim a weight to a very control area you are at the mercey of that area of the clutch being at a tru 120 degrees. Remember you are pushing around alot of weight and you can hurt the balance ALOT . Always make sure the weight is tracking as close to dead center in the spider roller as you can get it.

Next post may surprise some of you.

Dan

Crank run-out

With all the crank trouble that has surfaced in the past 8 years with big twins...........

Some people have gotten............ lets just say, alittle over careful with clutch stuff.

Ok, people have heard me say........... Do NOT check crank run-out ( just because you think you should ) why you ask.............

Reason being.............Cranks go in and out of tru once and awhile.

explanation - lets say you hit a big junk and go air born and land with the throttle close to or wide open. ( studded track Or a big mountain track. ) onto to a good traction surface. the huge jerk on the drive clutch will knock the crank out of tru.

Heres where it gets alittle if'y -

#1 - if you have a perfect fit on the crankcase and it has a nice tru bore and the correct crush on the bearings ( Number one the crank will not go out of tru all that much ) because the fit is good. That being said the crank will go right back into tru as you drive. Some people have felt this. ( they feel a vibration and all of a sudden its gone ) You now know what happened.

#2 - If you have a poor fitting crankcase, and you jump your sled and jerk the crank out of tru ( it will out of tru worse then it should, And fail to tru its self like it should. )

#3 - When a Domestic Polaris case starts to warm-up and the crank is frozen the case actually looses its hold on the crank until the crank gets heat soaked and the clutch is now jerking on the rod pin which is located

" X " number of millimeters from the center line of the crank. ( This is where the PTO Lock ring bearing comes into play ) When the case is warming up ( thermostat closed ) the case will actually grow just over .002 thou bigger then the bearing if the motor started out at Zero degrees F. during this time when the crank temp is far behind the case the lock ring bearing feels the jerk instead of the rod pin.

How do I know this you ask...............I have seen many examples ( to keep it short i will tell you one. Two years ago I line bored a case for a customer ( before I was machining in the lock ring groove into the PTO area. ) I had a customer call ( I believe his name was Burkley Johnson from Colorado) and ask me if he could send his crank and case back and get the Torque Master Lock ring machined in and the lock ring bearing installed................He said all has been running good but he said he had pulled the clutch and the crank had about .0035 thou run-out. I said ok.........what ever you wish.

weeks later he called and said.........Dan I pulled the motor and I am sending it in for the lock ring groove update. He then said, Dan you may find this strange......I rechecked the run-out and its now only a 1/2 thou out of tru ( .0005 ) he said I know I'm not crazy - It was Three & 1/2 Thou Out ( .0035 ).

This is why I do not like checking crank run out. There is alot of tramma apply to the crank while removing a drive clutch.

Moral of the story. If you have any feel at all............. Just ride your sled, If you get a bad feeling that something has change and its NOT getting better ( maybe even worse ) thats cause to check things out.

If you ride alot and know your sled well you can feel the difference from .0005 to .0035 vary easily.

Once a crank gets to far out even a great case can't hold it.

Once its bent so far the weight alone of the drive clutch will rip the PTO-end off like many Polaris 900's do.

I hope this helps you see into the clutch thing alittle more.

People that take time to heat soak their motors will see less trouble then those who don't. ( If all things being equal ).

Dan

With all the crank trouble that has surfaced in the past 8 years with big twins...........

Some people have gotten............ lets just say, alittle over careful with clutch stuff.

Ok, people have heard me say........... Do NOT check crank run-out ( just because you think you should ) why you ask.............

Reason being.............Cranks go in and out of tru once and awhile.

explanation - lets say you hit a big junk and go air born and land with the throttle close to or wide open. ( studded track Or a big mountain track. ) onto to a good traction surface. the huge jerk on the drive clutch will knock the crank out of tru.

Heres where it gets alittle if'y -

#1 - if you have a perfect fit on the crankcase and it has a nice tru bore and the correct crush on the bearings ( Number one the crank will not go out of tru all that much ) because the fit is good. That being said the crank will go right back into tru as you drive. Some people have felt this. ( they feel a vibration and all of a sudden its gone ) You now know what happened.

#2 - If you have a poor fitting crankcase, and you jump your sled and jerk the crank out of tru ( it will out of tru worse then it should, And fail to tru its self like it should. )

#3 - When a Domestic Polaris case starts to warm-up and the crank is frozen the case actually looses its hold on the crank until the crank gets heat soaked and the clutch is now jerking on the rod pin which is located

" X " number of millimeters from the center line of the crank. ( This is where the PTO Lock ring bearing comes into play ) When the case is warming up ( thermostat closed ) the case will actually grow just over .002 thou bigger then the bearing if the motor started out at Zero degrees F. during this time when the crank temp is far behind the case the lock ring bearing feels the jerk instead of the rod pin.

How do I know this you ask...............I have seen many examples ( to keep it short i will tell you one. Two years ago I line bored a case for a customer ( before I was machining in the lock ring groove into the PTO area. ) I had a customer call ( I believe his name was Burkley Johnson from Colorado) and ask me if he could send his crank and case back and get the Torque Master Lock ring machined in and the lock ring bearing installed................He said all has been running good but he said he had pulled the clutch and the crank had about .0035 thou run-out. I said ok.........what ever you wish.

weeks later he called and said.........Dan I pulled the motor and I am sending it in for the lock ring groove update. He then said, Dan you may find this strange......I rechecked the run-out and its now only a 1/2 thou out of tru ( .0005 ) he said I know I'm not crazy - It was Three & 1/2 Thou Out ( .0035 ).

This is why I do not like checking crank run out. There is alot of tramma apply to the crank while removing a drive clutch.

Moral of the story. If you have any feel at all............. Just ride your sled, If you get a bad feeling that something has change and its NOT getting better ( maybe even worse ) thats cause to check things out.

If you ride alot and know your sled well you can feel the difference from .0005 to .0035 vary easily.

Once a crank gets to far out even a great case can't hold it.

Once its bent so far the weight alone of the drive clutch will rip the PTO-end off like many Polaris 900's do.

I hope this helps you see into the clutch thing alittle more.

People that take time to heat soak their motors will see less trouble then those who don't. ( If all things being equal ).

Dan

No hammer?

A good clutch puller is available from many sources including Polaris. Remove the clutch bolt and insert the puller-tighten till the clutch comes off. There are various methods of holding the clutch while you tighten the bolt; I like a strap wrench or holding tool. A 2X4 braced against the chassis and the clutch also works on some sleds. I don’t care for removing a spark plug and putting rope in to lock the piston nor do I like placing a bar through the clutch. Avoid anything that may stress your crank. Most dealers use an impact wrench-if you do then hold the clutch with one hand. Use an Impact gun as last resort & never hit the end of the puller with a hammer…Ever wonder why some cranks last longer than others?

I just barely tapped the puller with a hammer and the clutch popped right off. Didn't seem too offending to crank? Otherwise it seemed like I was really going to have to torque on the wrench/spider holder.

A good clutch puller is available from many sources including Polaris. Remove the clutch bolt and insert the puller-tighten till the clutch comes off. There are various methods of holding the clutch while you tighten the bolt; I like a strap wrench or holding tool. A 2X4 braced against the chassis and the clutch also works on some sleds. I don’t care for removing a spark plug and putting rope in to lock the piston nor do I like placing a bar through the clutch. Avoid anything that may stress your crank. Most dealers use an impact wrench-if you do then hold the clutch with one hand. Use an Impact gun as last resort & never hit the end of the puller with a hammer…Ever wonder why some cranks last longer than others?

I just barely tapped the puller with a hammer and the clutch popped right off. Didn't seem too offending to crank? Otherwise it seemed like I was really going to have to torque on the wrench/spider holder.

R

Ron

ACCOUNT CLOSED

A good clutch puller is available from many sources including Polaris. Remove the clutch bolt and insert the puller-tighten till the clutch comes off. There are various methods of holding the clutch while you tighten the bolt; I like a strap wrench or holding tool. A 2X4 braced against the chassis and the clutch also works on some sleds. I don’t care for removing a spark plug and putting rope in to lock the piston nor do I like placing a bar through the clutch. Avoid anything that may stress your crank. Most dealers use an impact wrench-if you do then hold the clutch with one hand. Use an Impact gun as last resort & never hit the end of the puller with a hammer…Ever wonder why some cranks last longer than others?

I just barely tapped the puller with a hammer and the clutch popped right off. Didn't seem too offending to crank? Otherwise it seemed like I was really going to have to torque on the wrench/spider holder.

Just giving my opinion, but I have never had to use a hammer to remove a clutch. It's not likely that there is any factual evidence relating to most crank failure but why do anything to stress the crank that's not necessary. One could argue that a "tap" would not hurt anything but any rap on the puller travels throught the crank components also. Personally I'd prefer the rotational force of an impact gun to a rap on the puller but I have no way of arguing the point.

I have seen people put pressure on the puller bolt then put a little bit of heat at a time to the clutch and it comes right off. Is this ok or does it do something bad?

R

Ron

ACCOUNT CLOSED

I have seen people put pressure on the puller bolt then put a little bit of heat at a time to the clutch and it comes right off. Is this ok or does it do something bad?

"Quote from original instructions"

TIP-A stubborn clutch will usually come free with application of heat to the inner sheave. Try a spot of grease on the tip of the puller and Teflon on the threads for more leverage. Put your heat gun on high and turn the clutch to apply heat evenly. Apply more pressure on the puller and apply more heat.

If this still doesn't get the clutch free, {AS A LAST RESORT} I prefer to use an impact gun while holding the clutch firmly so the engine internals don't rattle.

With all the crank trouble that has surfaced in the past 8 years with big twins...........

Some people have gotten............ lets just say, alittle over careful with clutch stuff.

Ok, people have heard me say........... Do NOT check crank run-out ( just because you think you should ) why you ask.............

Reason being.............Cranks go in and out of tru once and awhile.

explanation - lets say you hit a big junk and go air born and land with the throttle close to or wide open. ( studded track Or a big mountain track. ) onto to a good traction surface. the huge jerk on the drive clutch will knock the crank out of tru.

Heres where it gets alittle if'y -

#1 - if you have a perfect fit on the crankcase and it has a nice tru bore and the correct crush on the bearings ( Number one the crank will not go out of tru all that much ) because the fit is good. That being said the crank will go right back into tru as you drive. Some people have felt this. ( they feel a vibration and all of a sudden its gone ) You now know what happened.

#2 - If you have a poor fitting crankcase, and you jump your sled and jerk the crank out of tru ( it will out of tru worse then it should, And fail to tru its self like it should. )

#3 - When a Domestic Polaris case starts to warm-up and the crank is frozen the case actually looses its hold on the crank until the crank gets heat soaked and the clutch is now jerking on the rod pin which is located

" X " number of millimeters from the center line of the crank. ( This is where the PTO Lock ring bearing comes into play ) When the case is warming up ( thermostat closed ) the case will actually grow just over .002 thou bigger then the bearing if the motor started out at Zero degrees F. during this time when the crank temp is far behind the case the lock ring bearing feels the jerk instead of the rod pin.

How do I know this you ask...............I have seen many examples ( to keep it short i will tell you one. Two years ago I line bored a case for a customer ( before I was machining in the lock ring groove into the PTO area. ) I had a customer call ( I believe his name was Burkley Johnson from Colorado) and ask me if he could send his crank and case back and get the Torque Master Lock ring machined in and the lock ring bearing installed................He said all has been running good but he said he had pulled the clutch and the crank had about .0035 thou run-out. I said ok.........what ever you wish.

weeks later he called and said.........Dan I pulled the motor and I am sending it in for the lock ring groove update. He then said, Dan you may find this strange......I rechecked the run-out and its now only a 1/2 thou out of tru ( .0005 ) he said I know I'm not crazy - It was Three & 1/2 Thou Out ( .0035 ).

This is why I do not like checking crank run out. There is alot of tramma apply to the crank while removing a drive clutch.

Moral of the story. If you have any feel at all............. Just ride your sled, If you get a bad feeling that something has change and its NOT getting better ( maybe even worse ) thats cause to check things out.

If you ride alot and know your sled well you can feel the difference from .0005 to .0035 vary easily.

Once a crank gets to far out even a great case can't hold it.

Once its bent so far the weight alone of the drive clutch will rip the PTO-end off like many Polaris 900's do.

I hope this helps you see into the clutch thing alittle more.

People that take time to heat soak their motors will see less trouble then those who don't. ( If all things being equal ).

Dan

That was a very good explanition and very helpful.

When you mention this "jerk" or load applied to a drive clutch how does this relate to engine mounts. Is it the load itself that pulls the crank out of true and (or) the block being pulled out of position and placing abnormal thrust and side presure on the PTO bearings.

I guess a better way to ask that, do the aftermarket mounts prevent crank distortion under load ?

Thanks this has been a great post all the way around

Better explaination

I was refering to two different types of Jerk on the crank.

#1 - a straight " jerk " back on the drive clutch applied by the driven, When a fast spinning track hooks or grabs something very hard.

#2 - A slide hammer type " jerk " applied by the drive clutch at engagement, when the moveable sheave comes in contact with the belt it is getting is leverage from the stationary sheave wheich is hooked to the crank.

One I did't mention, Blowing a belt at full throttle unloads the motor so fast that the crank actually bows and many times comes in contact with the case ( Few of you may have seen this,) Aluminum strips on the center seal hub that has been shmeared. after a belt has been blowen at high speed most cranks are at that point knocked out of tru to some degree. ( a good tight case will sometimes re-tru it to a point ) normally not as good as it once was.

As for the motor mounts, The more torque stops you add to your motor, the more energy you drive into the crankshaft, and the less energy that goes into the motor mounts.

The is why I hate torque ( arms ) and prefer torque ( stops ) Stops should be installed with clearance .060 to .100 thou and NEVER be up against the motor ( unless ) your a drag racer and winning comes first and the crank caomes second.

Imagin, when there are no torque arms or stops............ all the motor mounts absorb some of this energy, torque stops and arms can really screw things up if not installed with some thought of what you want out of them.

That was a very good explanition and very helpful.

When you mention this "jerk" or load applied to a drive clutch how does this relate to engine mounts. Is it the load itself that pulls the crank out of true and (or) the block being pulled out of position and placing abnormal thrust and side presure on the PTO bearings.

I guess a better way to ask that, do the aftermarket mounts prevent crank distortion under load ?

Thanks this has been a great post all the way around

I was refering to two different types of Jerk on the crank.

#1 - a straight " jerk " back on the drive clutch applied by the driven, When a fast spinning track hooks or grabs something very hard.

#2 - A slide hammer type " jerk " applied by the drive clutch at engagement, when the moveable sheave comes in contact with the belt it is getting is leverage from the stationary sheave wheich is hooked to the crank.

One I did't mention, Blowing a belt at full throttle unloads the motor so fast that the crank actually bows and many times comes in contact with the case ( Few of you may have seen this,) Aluminum strips on the center seal hub that has been shmeared. after a belt has been blowen at high speed most cranks are at that point knocked out of tru to some degree. ( a good tight case will sometimes re-tru it to a point ) normally not as good as it once was.

As for the motor mounts, The more torque stops you add to your motor, the more energy you drive into the crankshaft, and the less energy that goes into the motor mounts.

The is why I hate torque ( arms ) and prefer torque ( stops ) Stops should be installed with clearance .060 to .100 thou and NEVER be up against the motor ( unless ) your a drag racer and winning comes first and the crank caomes second.

Imagin, when there are no torque arms or stops............ all the motor mounts absorb some of this energy, torque stops and arms can really screw things up if not installed with some thought of what you want out of them.

You make a good point allowing the motor mounts to absorb shock. I never really thought locking the motor down real tight was a good plan.

I hope I never need your services but if I do, well I know where to come

Thanks for your posts

I hope I never need your services but if I do, well I know where to come

Thanks for your posts

R

Ron

ACCOUNT CLOSED

Just a couple more thoughts on belts & side clearance measurements.

Your new IQ 7 & 8 comes from Poo with the 115 belt. Many of you will purchase the 080 belt for a spare & that's fine except that at some point you may start using the spare belt & that will change belt side clearance. Even the 115 belts aren't the same width so changing belts may require a change to side clearance. (Changing to an A/Mkt weight can change side clearance too.)

This makes a good argument for spending the extra $ for another 115 belt & try to get 2 that are the same width. Another argument for the 115 is that they are nearly indestructable so they won't blow up putting stess on the crank. Normally, the 115 will wear until it's too narrow rather than grenade like the 080.

So if you are adding an A/M clutch kit from Carl's or SLP then put in the new weights before checking side clearance. In a perfect world you should also break-in the belts or at least recheck clearance after you have some miles on your belts. Yes.......belts.......break-in the spare belt as well as the one on the sled.

And don't forget to scrub both belts to remove the mold release agent. I use a powder cleanser like BonAmi, wire brush & lots of hot water.

The clutch & belts are a good place to get a little ANAL!!!!

Your new IQ 7 & 8 comes from Poo with the 115 belt. Many of you will purchase the 080 belt for a spare & that's fine except that at some point you may start using the spare belt & that will change belt side clearance. Even the 115 belts aren't the same width so changing belts may require a change to side clearance. (Changing to an A/Mkt weight can change side clearance too.)

This makes a good argument for spending the extra $ for another 115 belt & try to get 2 that are the same width. Another argument for the 115 is that they are nearly indestructable so they won't blow up putting stess on the crank. Normally, the 115 will wear until it's too narrow rather than grenade like the 080.

So if you are adding an A/M clutch kit from Carl's or SLP then put in the new weights before checking side clearance. In a perfect world you should also break-in the belts or at least recheck clearance after you have some miles on your belts. Yes.......belts.......break-in the spare belt as well as the one on the sled.

And don't forget to scrub both belts to remove the mold release agent. I use a powder cleanser like BonAmi, wire brush & lots of hot water.

The clutch & belts are a good place to get a little ANAL!!!!

Great post guy's....I also want to stress how important it is, as Dan said, to heat soak your motor as soon as you get it off the show room floor and into your garage.

I hope, knock on wood, that this is the reason I haven't lost a crank.

Take the time and don't ride it like you stole it the first time out and hopefully you won't need a tow.

I hope, knock on wood, that this is the reason I haven't lost a crank.

Take the time and don't ride it like you stole it the first time out and hopefully you won't need a tow.

Just a couple more thoughts on belts & side clearance measurements.

Your new IQ 7 & 8 comes from Poo with the 115 belt. Many of you will purchase the 080 belt for a spare & that's fine except that at some point you may start using the spare belt & that will change belt side clearance. Even the 115 belts aren't the same width so changing belts may require a change to side clearance. (Changing to an A/Mkt weight can change side clearance too.)

This makes a good argument for spending the extra $ for another 115 belt & try to get 2 that are the same width. Another argument for the 115 is that they are nearly indestructable so they won't blow up putting stess on the crank. The 115 will wear until it's too narrow rather than grenade like the 080.

So if you are adding an A/M clutch kit from Carl's or SLP then put in the new weights before checking side clearance. In a perfect world you should also break-in the belts or at least recheck clearance after you have some miles on your belts. Yes.......belts.......break-in the spare belt as well as the one on the sled.

And don't forget to scrub both belts to remove the mold release agent. I use a powder cleanser like BonAmi, wire brush & lots of hot water.

The clutch & belts are a good place to get a little ANAL!!!!

hate to say it guys..I exploded a 115 belt last year...running about 40 mph across a lake in about 4 inches of snow..just boomed into a pile of peices..thought I lost a mnt or something..but clutches were cool to the touch and after cleaning up the mess it is still running the spare I put on that day(original belt blew with 880 miles spare now has 1100 miles on it), my guess is the belt just failed..memory showed 8735 rpm from 1/4 throttle ..imagine what it would be at full throttle climb rpm and a belt let go...

S

sodfarmer

Member

Thank you Ron and Indy Dan. Dan Your posts on cranks on the old forum have helped me alot. I have been much more careful with warming up the motor. This year I got a didatron to help monitor things more carefully. How warm should the water temp be before I shut down to allow heat soak? Also the post on the old forum on c3 and c4 bearings was a gem.

Thanks for sharing your knowledge.

Thanks for sharing your knowledge.

Ron and Dan, great posts

Thanks

Thanks

Thanks Ron for the info

R

Ron

ACCOUNT CLOSED

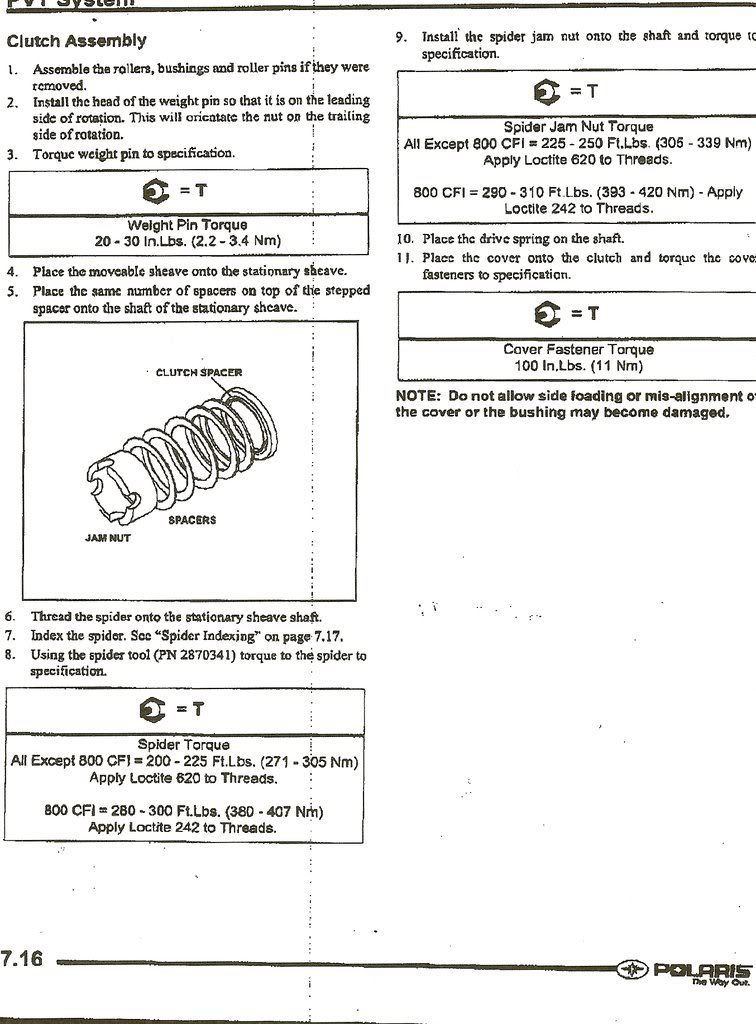

SW member SuprerD8 reported the following change to torque for the P85 spider & lock nut. I verified that Polaris increased recommended torque with Carl's today. SD8 quotes:

"P85 everything but 800cfi

#200 spider

#225 Lock nut

P85 on 800Cfi

#290-300 spider

#300-330 lock nut"

This might work well at the factory where they have all the right tools.

The reality is it's very difficult to torque the spider & especially the lock nut-most of us don't have a torque wrench that goes over 200 #'s & the tool for the lock nut wants to pop off the nut when a lot of torque is applied. Carl's Cycle uses a 4' cheater bar (no torque wrench) to reinstall the helix & lock nut. That's exactly what I use & I have someone stand on top of the bar to keep the tool from popping loose. I'm going to guess that a 200# fella putting his shoulder into the process will apply enough torque to the clutch.

The downside is that if you don't get enough torque the spider will come loose changing belt side clearance & should be apparent quickly. You are done riding until you fix it. You can screw the spider back hand tight to get your sled back to the truck.

"P85 everything but 800cfi

#200 spider

#225 Lock nut

P85 on 800Cfi

#290-300 spider

#300-330 lock nut"

This might work well at the factory where they have all the right tools.

The reality is it's very difficult to torque the spider & especially the lock nut-most of us don't have a torque wrench that goes over 200 #'s & the tool for the lock nut wants to pop off the nut when a lot of torque is applied. Carl's Cycle uses a 4' cheater bar (no torque wrench) to reinstall the helix & lock nut. That's exactly what I use & I have someone stand on top of the bar to keep the tool from popping loose. I'm going to guess that a 200# fella putting his shoulder into the process will apply enough torque to the clutch.

The downside is that if you don't get enough torque the spider will come loose changing belt side clearance & should be apparent quickly. You are done riding until you fix it. You can screw the spider back hand tight to get your sled back to the truck.

R

Ron

ACCOUNT CLOSED

P85 Torque

Here is a copy of info rec'd from SuperD8. Note higher torque plus Loctite 242 for 800 CFI's. Looks like overkill to me!

Blue Threadlocker (248, 242)

Material: Dimethacrylate ester

Application:

For use on mounting bolts, pumps and compressors

Recommended for fasteners from 1/4" through 3/4"

Cures in 10 minutes, full strength in 24 hours

Medium strength, requires handtools to remove once applied

Non-wicking

Here is a copy of info rec'd from SuperD8. Note higher torque plus Loctite 242 for 800 CFI's. Looks like overkill to me!

Blue Threadlocker (248, 242)

Material: Dimethacrylate ester

Application:

For use on mounting bolts, pumps and compressors

Recommended for fasteners from 1/4" through 3/4"

Cures in 10 minutes, full strength in 24 hours

Medium strength, requires handtools to remove once applied

Non-wicking

what about doing the old hydrolic method of getting the clutch off? I have never done it but know some people that have???

I lost an 80 poo belt last year on the 1200 runnin across a lake, probably gunna try out some 115's this year (If I can afford them!)

I lost an 80 poo belt last year on the 1200 runnin across a lake, probably gunna try out some 115's this year (If I can afford them!)

Similar threads

D

- Replies

- 0

- Views

- 250

D

T

- Replies

- 2

- Views

- 687

S

T

- Replies

- 2

- Views

- 360

T

- Replies

- 2

- Views

- 935