Here at PES we were tired of stripping out the helix bolts on the Polaris secondary clutches and having to pay a crazy price from Polaris to replace them. They just raised the price to $8 each!!

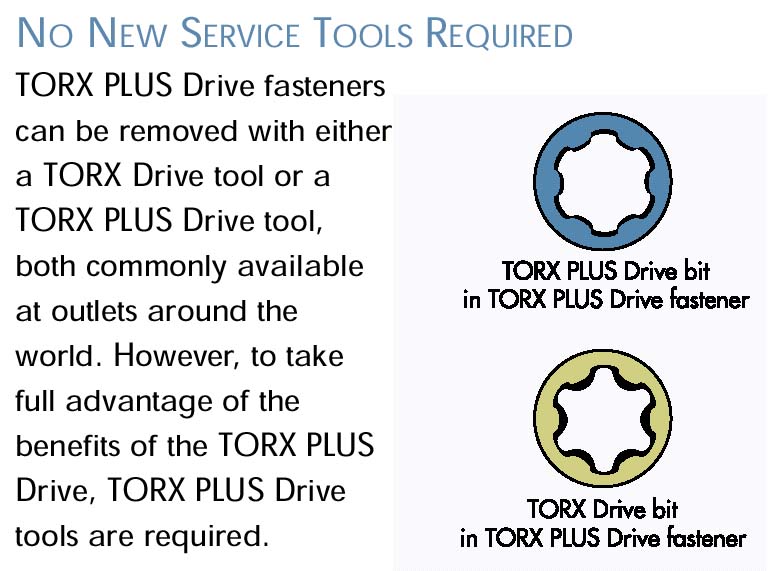

We knew there was a better way so we sourced our own solution. Our bolts use a larger drive (T-30 vs T-27) which helps prevent stripping and our bolts also feature a Torx-Plus drive design which maximizes bit surface area to prevent stripping and can be used with the traditional Torx bits you already have or you can upgrade to a Torx-Plus bit for even better grip.

In summary: You get a much better bolt for only 1/4 the price.

See Pricing on our website or in the swapmeet here: http://www.snowest.com/forum/showthread.php?p=3954742#post3954742

We knew there was a better way so we sourced our own solution. Our bolts use a larger drive (T-30 vs T-27) which helps prevent stripping and our bolts also feature a Torx-Plus drive design which maximizes bit surface area to prevent stripping and can be used with the traditional Torx bits you already have or you can upgrade to a Torx-Plus bit for even better grip.

In summary: You get a much better bolt for only 1/4 the price.

See Pricing on our website or in the swapmeet here: http://www.snowest.com/forum/showthread.php?p=3954742#post3954742

Last edited: