Those reeds are bad but not bad enough to run that bad. I have changed reeds like that on my turbo and never even known they were bad because the sled still ran good. I have had similar problems with my pl box, and it has always been a problem of the box getting wet, once i dry it out it all comes back in line. for me when it happens the box won't sense boost, and you can tell because your boost wiil come on but you won't get a blue light on the box. Also check your fuel pressure under boost should be around 64 psi at 12lbs. I had my sled out for the first ride the other day and was getting over 100 psi fuel pressure on boost, ran really bad took a few to figure it out, but remembered that when I ran new line to my fuel regulator i forget to put restrictor in boost line to regulator, probably not your problem but regulators do go bad.

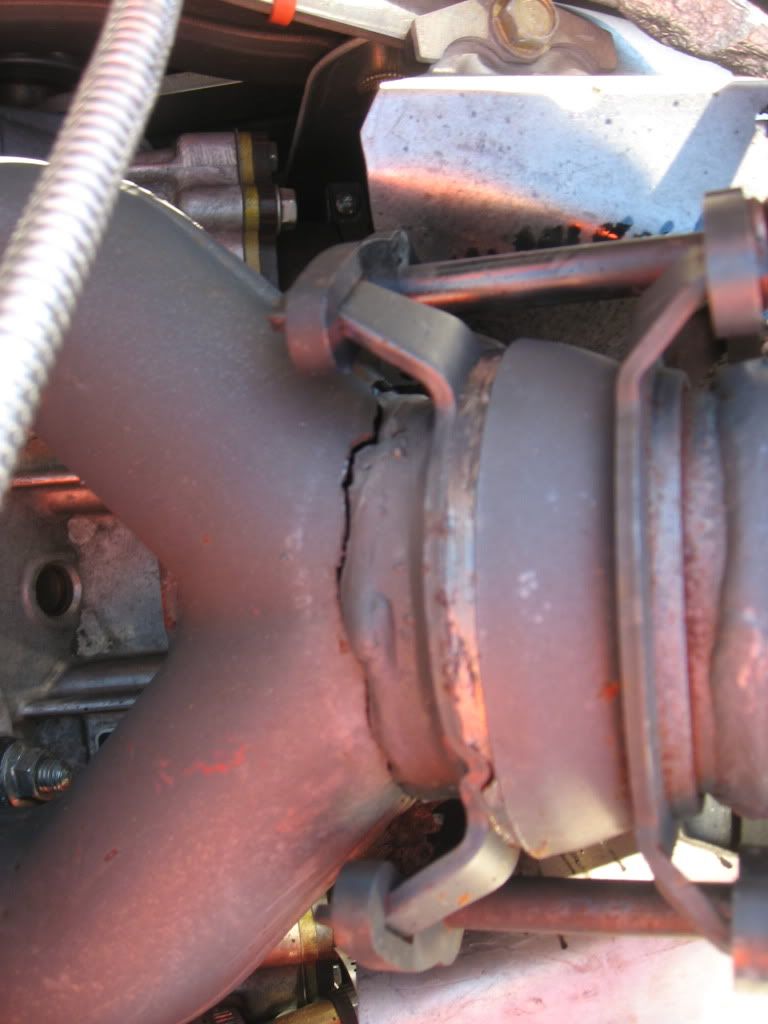

That's what I was kind of afraid of, you would think that it still should have pulled good under boost. Well, I'll get some new reeds, put her together and see what happens. Maybe, just maybe, this is all that is wrong with it.