I

IQRIDR

Well-known member

First off, I want to make it clear- I am not bashing a product here. I am posting my objective experience with a product. Lots of people are asking and contacting me regarding how the kit ran and I, as a long time member here on Snowest and a shop owner I feel obligated to set the drama aside and simply post the facts.

When the 858 motor first got out on the snow, it ran great once the fueling was dialed in. Pulled massive track speed, motor sounded very healthy, everything was good. Then, I lost a rod bearing after about 50-60 miles. Crank was done. At this point, the sled needed a new piston on the mag side (mag rod bearing scored it up) but already had some scuffing on the PTO piston as well. This concerned me but I was assured that it could be run again once it was cleaned up a little with a scotch brite pad.

The cylinder also had some interesting scoring...I have my opinion about it, RKT has theirs, I suppose the cylinder plating company would have one also. I will let you form your own.

I then rebuilt the motor with a new crank and 1 new piston. It ran great, again, for about 5 rides or so, then started losing power and compression slowly. I dissembled the motor to find 2 heavily scuffed pistons and the cylinder looking and feeling worse than before.

I believe that there are some problems with this kit that can most definitely be solved, but it has been brought to my attention that people are being informed that the sled ran great for a lot of miles and is still running. The 858 kit got a total of just under 350 miles on my sled the 2 times it was installed. I have since reinstalled a stock cylinder and pistons with my previous head and pipe setup. I do not want people to be misled or under the impression that the kit had no problems. I will be sending the pistons back to RKT for inspection.

Normally I would have continued to keep all this to myself but I feel morally obligated to the industry and my shop's reputation to put the facts out there and let them speak for themselves. This kit DID RUN GREAT but it does have problems that need to be addressed and to be honest I am sure RKT will address them and have a good running, cost effective bang-for-the-buck kit. This was a one-off kit.

I want to make it clear that there is nothing wrong with the sled as far as snow ingestion, belt dust ingestion, oiling, etc...a picture of my stock piston with 2438 miles on it will attest to that..no significant scuffing or wear, in fact they looked pretty decent and still made perfect compression.

Stock piston, intake side (STOCK 2011 PISTONS, THESE ARE NOT THE 858 PISTONS)

Stock piston, exhaust side

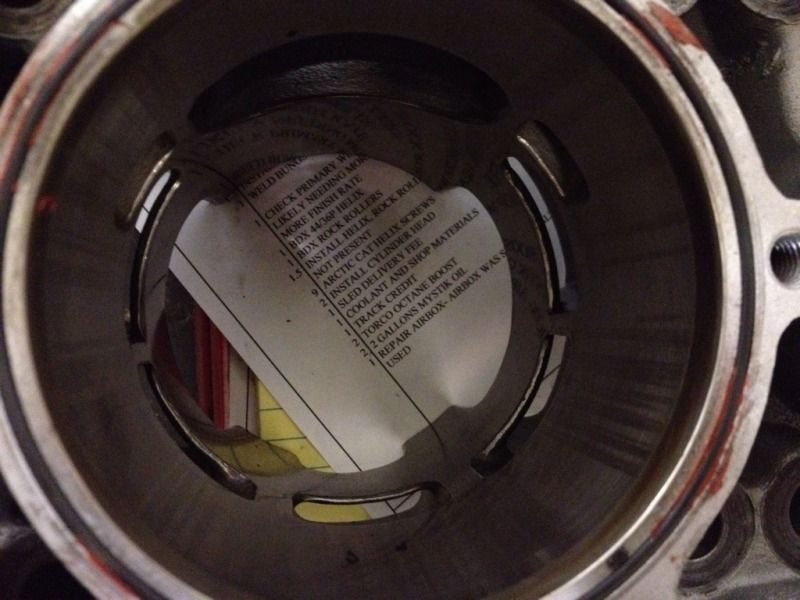

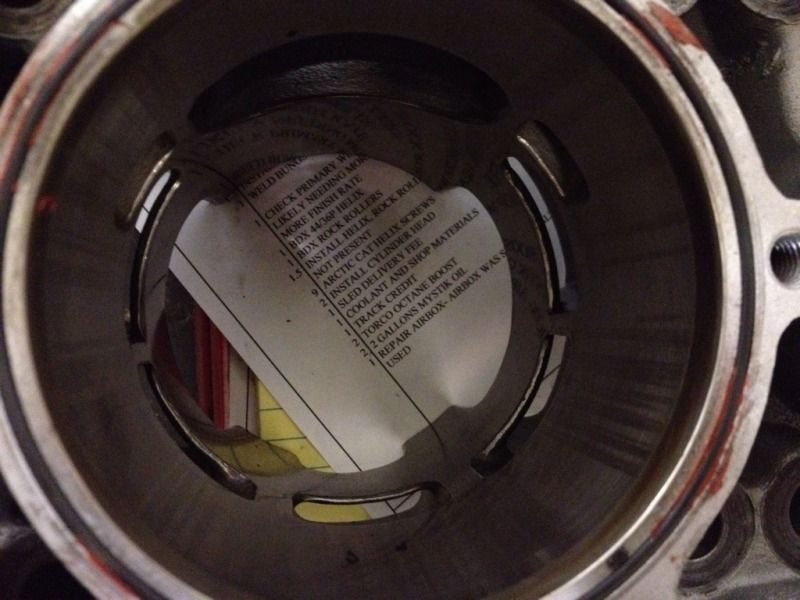

RKT 858 cylinder

Inevitably there will be people bashing me or disagreeing with my choice to post this here...but I got into this business for a few reasons with a set of specific principles and morals and I do not want to be responsible for people being misled or misinformed. Flame away.

When the 858 motor first got out on the snow, it ran great once the fueling was dialed in. Pulled massive track speed, motor sounded very healthy, everything was good. Then, I lost a rod bearing after about 50-60 miles. Crank was done. At this point, the sled needed a new piston on the mag side (mag rod bearing scored it up) but already had some scuffing on the PTO piston as well. This concerned me but I was assured that it could be run again once it was cleaned up a little with a scotch brite pad.

The cylinder also had some interesting scoring...I have my opinion about it, RKT has theirs, I suppose the cylinder plating company would have one also. I will let you form your own.

I then rebuilt the motor with a new crank and 1 new piston. It ran great, again, for about 5 rides or so, then started losing power and compression slowly. I dissembled the motor to find 2 heavily scuffed pistons and the cylinder looking and feeling worse than before.

I believe that there are some problems with this kit that can most definitely be solved, but it has been brought to my attention that people are being informed that the sled ran great for a lot of miles and is still running. The 858 kit got a total of just under 350 miles on my sled the 2 times it was installed. I have since reinstalled a stock cylinder and pistons with my previous head and pipe setup. I do not want people to be misled or under the impression that the kit had no problems. I will be sending the pistons back to RKT for inspection.

Normally I would have continued to keep all this to myself but I feel morally obligated to the industry and my shop's reputation to put the facts out there and let them speak for themselves. This kit DID RUN GREAT but it does have problems that need to be addressed and to be honest I am sure RKT will address them and have a good running, cost effective bang-for-the-buck kit. This was a one-off kit.

I want to make it clear that there is nothing wrong with the sled as far as snow ingestion, belt dust ingestion, oiling, etc...a picture of my stock piston with 2438 miles on it will attest to that..no significant scuffing or wear, in fact they looked pretty decent and still made perfect compression.

Stock piston, intake side (STOCK 2011 PISTONS, THESE ARE NOT THE 858 PISTONS)

Stock piston, exhaust side

RKT 858 cylinder

Inevitably there will be people bashing me or disagreeing with my choice to post this here...but I got into this business for a few reasons with a set of specific principles and morals and I do not want to be responsible for people being misled or misinformed. Flame away.

Last edited: