... unless you re-shim so your sheaves

One of my points... On my last 2 two-month road trips I DID take the time to check brand new, ready to deliver, sleds... all but one had anywhere near the 0.020" factory specified side clearance ....most were well above 0.060 (which gets worse as the belt wears). A few were less than 0.010" and 2 were at zero or worse. The average Joe does not know this and just rides and has premature belt wear or crank pin problems.

On these NEW sleds... all but one NEEDED to be re-shimmed.

.there's no reason to re-balance the clutch every year as some like to do. It is simply a waste of money

On this, my friend, we agree. Once it IS correct for shim and ballace, and IF it is maintained and belts are changed when worn out or the clutch is replaced when IT is worn out....then the balance should not need to be re-done. A worn out clutch cannot be balanced or rebuilt and should be scrapped.

Many shop that shim clutches don't put the extra time to index the clutch IF they even did take the time to shim the clutch to the PROPER factory specs (as specified to sled mfg by the clutch mfg)

-because, as I stated in my first post, rotating pieces of solid aluminum and steel cannot become "unbalanced".

Very true... Just don't let the primary get out of index or loose or worn.

And a good shop can get your sheaves indexed no matter what clearance you require.

A GOOD shop yes... or someone with the right specialty tools and the patience to do it.

Speaking to a clutch manufacturer that shall remain nameless but we all know,

In Mankato?

The mfg of these clutches uses a robotic balancer with Liberal tolerance specs for balance. Yes they are MUCH better than someone with basic balance equipment and a basic knowledge of use... but in the hands of the right machinist with the "right" machine... I am confident that a much better balanced clutch with smoother operation than stock is probable. Production requirements and QA checks are done only in random samples at the factory....Churn and burn.

I have taken a factory installed P-85 from a 2007 Dragon that was properly shimmed from the factory (if you can belive it

the less effect it has on vibration.

Though by their own admission has an effect that they cannot build for in order to be field serviceable. In my discussions with them, there can be a problem if the spider is out balance, then the clutch (as an assembly) is balanced to accommodate that out of tolerance spider (or button) and is then moved in the field to index for PROPER side clearance.

My other main point was to help people understand that factories-trust them or not-are using much more technologically advanced machines than we are exposed to

I'd add that is true for MOST of the shops we are exposed to, but not all.

to set belt to sheave clearance at 0 or near zero clearance not only takes away belt side force.....

Yes, I agree, zero side clearance is BAD.... 0.020" is Proper for a broken-in (not worn) belt.... MORE is BAD too as this will open up from normal belt wear... which is getting to be less of an issue with the newer PBO belts.

Also, factory belts vary much more than .010 in width, so to set your sheaves that closely together to begin with-and unless you know for certain you have the widest belt the factory ever manufactured to set your clearance to-is definitely not the best of practices.

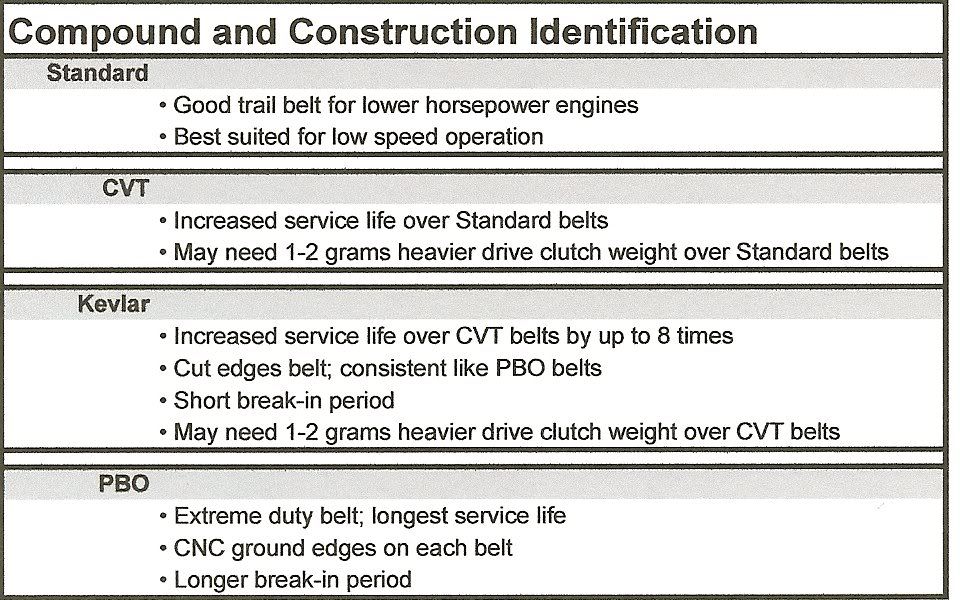

This has changed in recent years. The new cut and ground belts (chart below) are much more accurately made than just 5 years ago... unfortunately the price has gone up as well...

The PBO belts are cut THEN CNC ground for very tight belt-to-belt variance. In a box of 50 115 belts that I checked (I acutally only checked about 30 random ones in the box to be truthful) most on with a Starrett digi caliper... the variance was within .003" for width. So at least with the PBO belts.. you CAN set them more accurately and enjoy smoother clutch operation.

... It takes away the pinching force the weights have right off the get go.

That is why the factory that makes the clutches and most reputable clutch tuners do not set the clearance at zero... In this case 0.020"... More than that and you hammer the belt which will "scallop" the surface and cause premature belt and sheave wear.

The sheaves do not need to "slam" into the belt to prevent slippage... Again, the correct amount of clearance should be maintained.

And, yes, there are ways to set belt side clearance and still maintain proper weight tip in-even improve it-but I'm not here to sell anything

Like the Adjustable covers which I like... the downside is that they also change the pre load force and finishing force of the primary spring... for small changes this should not be that large of an issue.

If I read it correctly... you point is that many people are being "sold" on something that might not be necessary OR worse yet.... they are not getting ANY value for the money spent...

Some services do NOT give value.. others DO.. which is the point of the primary post in this thread

I agree with this AND I believe that the production of Primary clutches from AC and Polaris leaves much to be desired as sold to the end user. In my direct experience, I have made night and day differences to the performance of the sled, using the same springs and weights, by having the clutch setup done to match the factory specs AND be balanced very well.

Paul,

In answer to your question... the new belts from the big 4 on their top performers (like your XP, an M8, or the D-8's) are much more accurately mfg'd and are very consistent belt to belt... as pointed out above.. by nature the belt needs to be inherently balanced in the mfg procedure if it is to perform well... I believe the new generation of drive belts meets this goal.

As a sidebar... IMO.... take the time to break in your new belt AND the spare before you do any demanding riding (not when you are rushing to go "get some"...you will be happier in the end.

Last edited: