Hello, sorry I do not get one here often enough.

I was over on HCS forum and Answered a question past customer had about piston scuffing and I thought I would post it here so everyone is on the same page:

His cylinder finish looks to aggressive, I asked Does the back or your cylinder show a ( HG5 Finish ) signification ?

If it does not you can send the cylinder in and we will update the finish and supply you with a new set of Pistons no-Charge.

Over the past few seasons we have been studing Plated cylinder finishes at a feverish pace.

We have found that cross hatch is the enemy, and all these fancy coating are trying to protect the pistons at break in and long afterwards......

Last year 02/01/2015 we went to a new HG5 cyl finish that is Engraved on all our cylinders.

This finish has changed Piston, Ring & Life break-in proceedures to degree we cannot hardly believe.

That being said, 10/15/2015 we Upgraded to HG7 Cylinder Finish which is a finish that far Surpasses any other finish available......even by the OEM's.

The by Product of Plated Cylinders is a follows:

They are very porous and even when polished like Chrome they have a better ability to hold Oil then a perfectly cross Hatched Cast Iron cylinder that has been plateau Honed.

And as far as Ring break in goes......Not to worry most new rings are lapped-in round and do not require break it. ( And can start out with synthetic oil no problem, As far as brands of oil I am leaning more towards factory oil with new electric oil pumps. No oil will save a piston from a cylinder that is to aggressive. ) Connecting rods and more of a concern with these new motors with dry cases.

What does this mean to the Polaris owner ?

1 - Piston Life increased past what was ever thought possible. I now list 10,000 Miles on Piston interval on my TMX Long Rod motor.

2 - Break-in..... Not needed anymore.

Warm it up to engine temp, Shut it off and let it heat soak for 15 minutes, then restart and drive slowly until thermostat temp is reached and then ride it like a Rental. If it has HG7 Cyl Finish & the new OEM Polaris Pistons you can't hurt it.

You can etch this in Stone:

If you ever see a cylinder with our New HG7 Finish, ( And you will know it's something special when you see it ) You have seen the Best cylinder finish in the Industry and Most riders will never need Pistons again.

How do I know you may ask ?

Simple, In the last 3 years I have warrantied more Pistons then Polaris probably has in the History of the sport because of a Honing company selling Indy Specialty the ( Wrong super Abrasives )

Abrasives the Techs said were correct for Plated application.

In the last 3 years We have learned more about plated cylinder finish honing then I have about any other motor improvement in the last 32 years ( Regarding Honing )

If anyone out there has a cylinder from Indy Specialty that doesn't say:

HG5 or HG7 Engraved on the back of the Mag-Side Cylinder, You can send it back for HG7 Torque Plate Honing You will not be able to believe the difference even when you Start it.

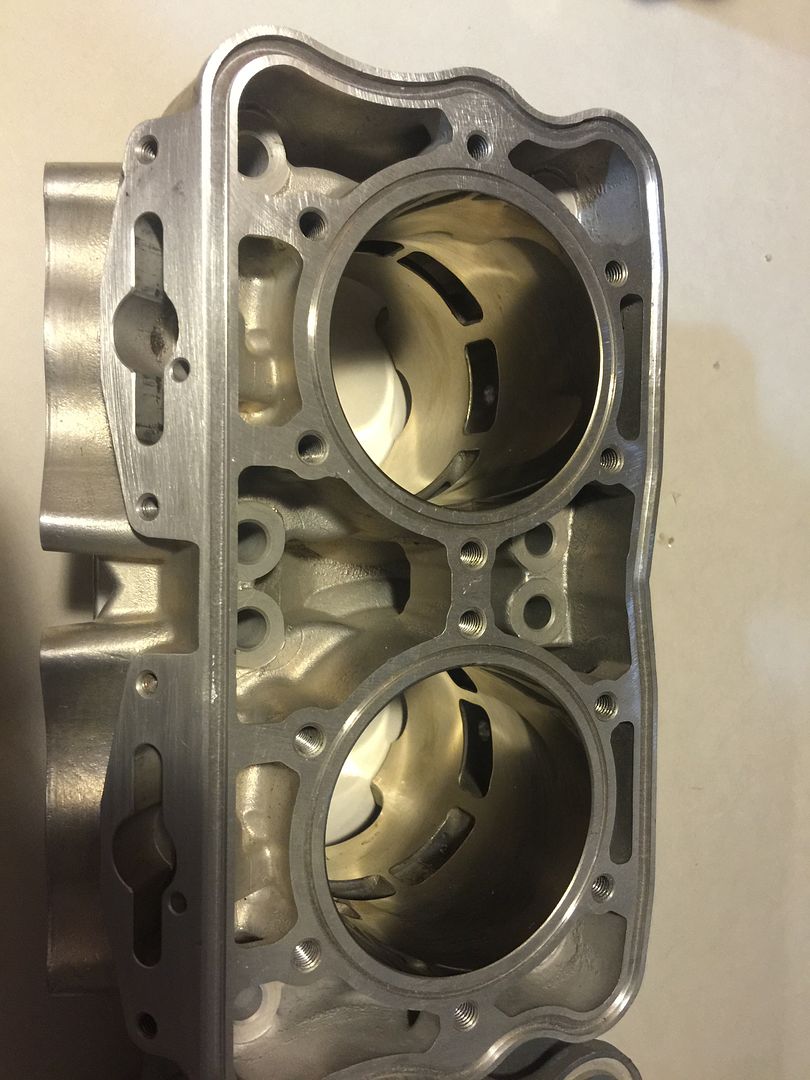

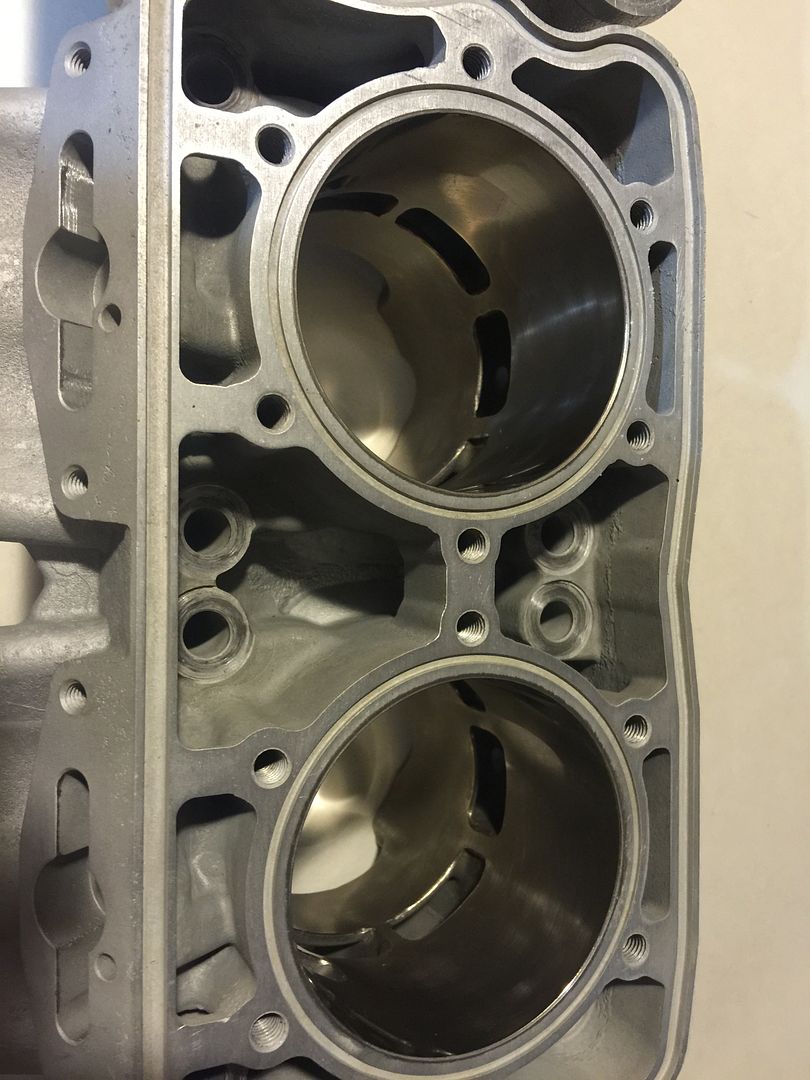

Please see the attached Photo below ( Plateau Honing ) The importance of this on a Cast Iron cylinder is important.

( Plateau Honing ) on a NiCad Plated cylinder is an absolute necessity !

The picture below shows what a Cast Iron cylinder looks like after correct Plateau Honing has been completed

And Plated cylinder will not just have the peaks polished off......95% created cross hatch will be gone>

Leaving a tremendously long flat surfaces for the Piston & Ring to guide on without wear.

A flat surface seen on a Cast Iron cylinder after break-in..........The problem with plated cylinders is this as follows:

Plated cylinders are far to hard to break in by an aluminum piston....The cylinder wears the piston & rings out long before it can get

the cylinder smooth enough.

It goes against what most engine builders believe ( me included for a long time ) ..........But.

Seeing little to No crossing is best........Cross hatch is the enemy of a plated cylinder.

Thank you.

IndyDan

I was over on HCS forum and Answered a question past customer had about piston scuffing and I thought I would post it here so everyone is on the same page:

His cylinder finish looks to aggressive, I asked Does the back or your cylinder show a ( HG5 Finish ) signification ?

If it does not you can send the cylinder in and we will update the finish and supply you with a new set of Pistons no-Charge.

Over the past few seasons we have been studing Plated cylinder finishes at a feverish pace.

We have found that cross hatch is the enemy, and all these fancy coating are trying to protect the pistons at break in and long afterwards......

Last year 02/01/2015 we went to a new HG5 cyl finish that is Engraved on all our cylinders.

This finish has changed Piston, Ring & Life break-in proceedures to degree we cannot hardly believe.

That being said, 10/15/2015 we Upgraded to HG7 Cylinder Finish which is a finish that far Surpasses any other finish available......even by the OEM's.

The by Product of Plated Cylinders is a follows:

They are very porous and even when polished like Chrome they have a better ability to hold Oil then a perfectly cross Hatched Cast Iron cylinder that has been plateau Honed.

And as far as Ring break in goes......Not to worry most new rings are lapped-in round and do not require break it. ( And can start out with synthetic oil no problem, As far as brands of oil I am leaning more towards factory oil with new electric oil pumps. No oil will save a piston from a cylinder that is to aggressive. ) Connecting rods and more of a concern with these new motors with dry cases.

What does this mean to the Polaris owner ?

1 - Piston Life increased past what was ever thought possible. I now list 10,000 Miles on Piston interval on my TMX Long Rod motor.

2 - Break-in..... Not needed anymore.

Warm it up to engine temp, Shut it off and let it heat soak for 15 minutes, then restart and drive slowly until thermostat temp is reached and then ride it like a Rental. If it has HG7 Cyl Finish & the new OEM Polaris Pistons you can't hurt it.

You can etch this in Stone:

If you ever see a cylinder with our New HG7 Finish, ( And you will know it's something special when you see it ) You have seen the Best cylinder finish in the Industry and Most riders will never need Pistons again.

How do I know you may ask ?

Simple, In the last 3 years I have warrantied more Pistons then Polaris probably has in the History of the sport because of a Honing company selling Indy Specialty the ( Wrong super Abrasives )

Abrasives the Techs said were correct for Plated application.

In the last 3 years We have learned more about plated cylinder finish honing then I have about any other motor improvement in the last 32 years ( Regarding Honing )

If anyone out there has a cylinder from Indy Specialty that doesn't say:

HG5 or HG7 Engraved on the back of the Mag-Side Cylinder, You can send it back for HG7 Torque Plate Honing You will not be able to believe the difference even when you Start it.

Please see the attached Photo below ( Plateau Honing ) The importance of this on a Cast Iron cylinder is important.

( Plateau Honing ) on a NiCad Plated cylinder is an absolute necessity !

The picture below shows what a Cast Iron cylinder looks like after correct Plateau Honing has been completed

And Plated cylinder will not just have the peaks polished off......95% created cross hatch will be gone>

Leaving a tremendously long flat surfaces for the Piston & Ring to guide on without wear.

A flat surface seen on a Cast Iron cylinder after break-in..........The problem with plated cylinders is this as follows:

Plated cylinders are far to hard to break in by an aluminum piston....The cylinder wears the piston & rings out long before it can get

the cylinder smooth enough.

It goes against what most engine builders believe ( me included for a long time ) ..........But.

Seeing little to No crossing is best........Cross hatch is the enemy of a plated cylinder.

Thank you.

IndyDan

Last edited: