What does this EPA L3 test look for,

NOx?

UHC?

Did a google search and couldnt find anything. You would think APT would advertise it. Someone pls link me if they have it.

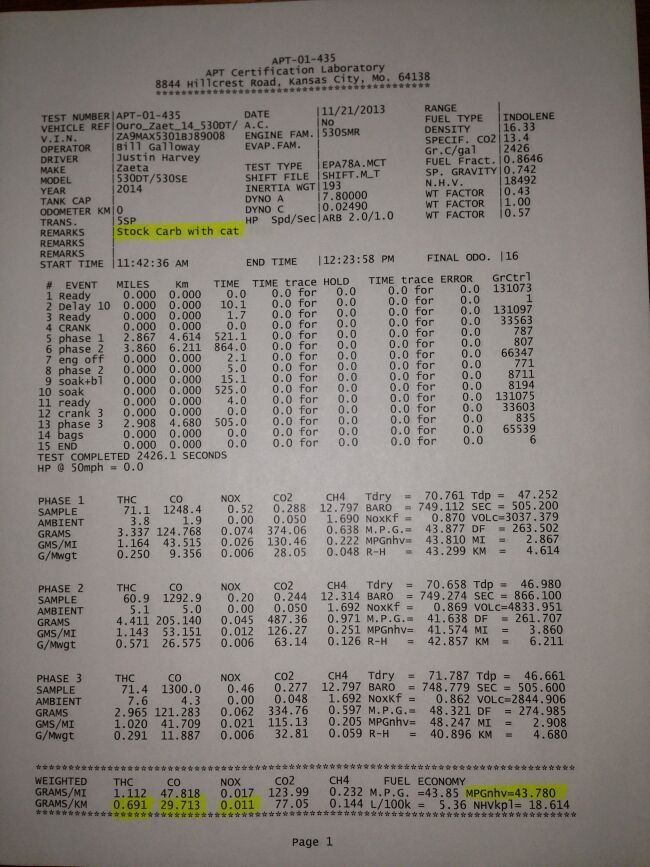

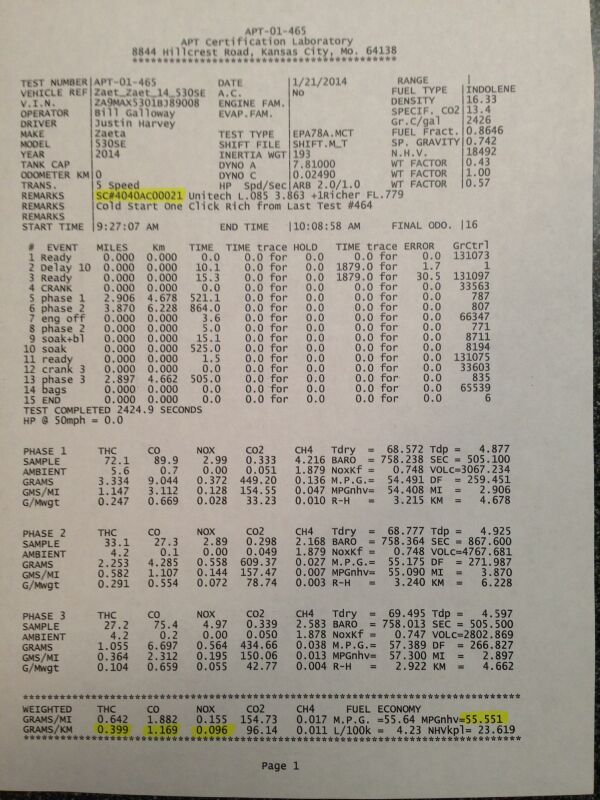

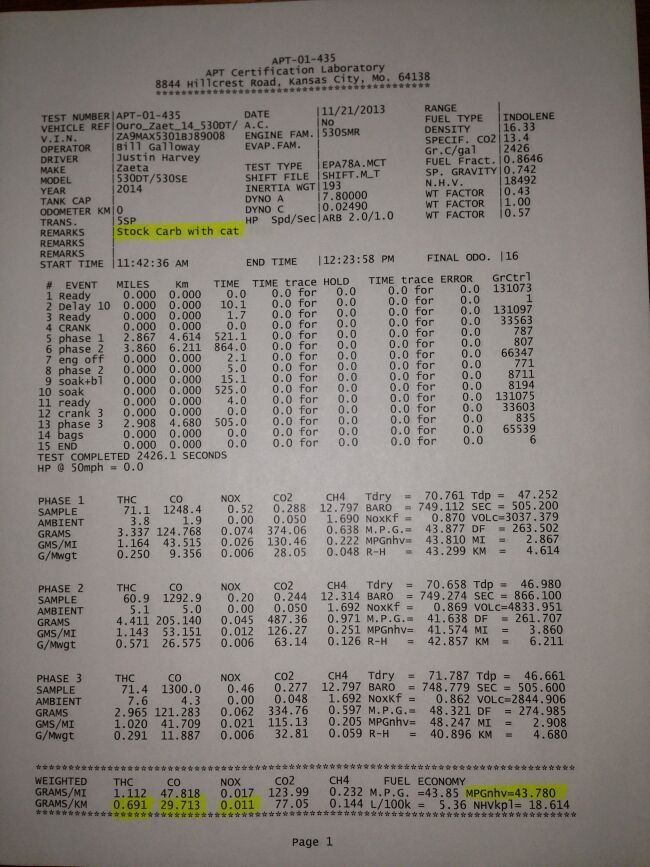

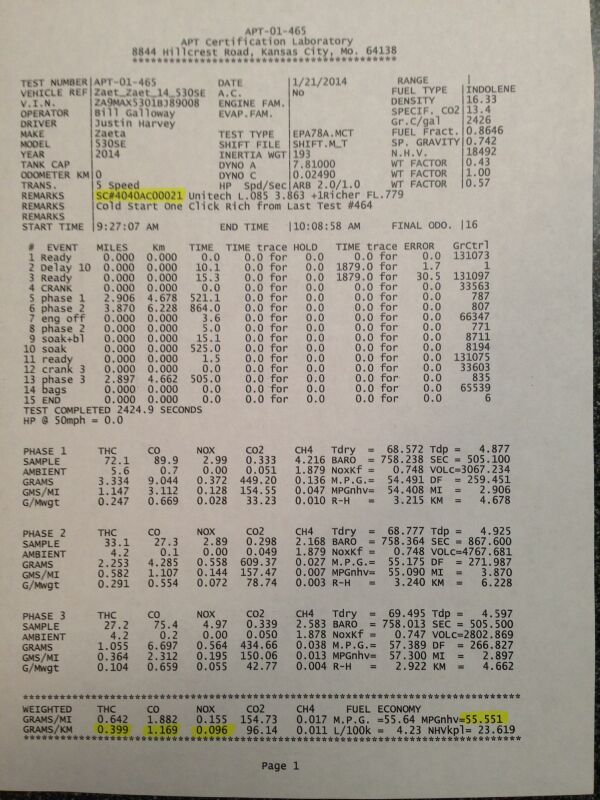

I believe there is some confusion regarding the emissions validations we are currently conducting, as I have explained them to Randy. The certification testing in question is being conducted on a Zaeta 530 DT four stroke street bike soon to be released in North America. This bike is powered by TM's open enduro race engine and comes equipped with a TMXX flatslide Mikuni Downdraft race carburetor and two catalysts. A fast light off catalyst in the head pipe and a heavily loaded 3-way cat in the pre-muffler. The goal was to achieve on road EPA Tier II and ARB Class I A on road motorcycle emissions certification with just the SC and no precious metal catalysts. What we ultimately wound up with was achieving the much more stringent EURO III emissions numbers (again without catalysts) and Zaeta picked us up as an OEM fuel system supplier for their European bikes as well. This of course has now sparked TM's interest in entering the US off road market with an emissions compliant open class offroad motorcycle. Below are two ECE R40 Class IA motorcycle emission trace tests.

Euro III emissions numbers are:

.8 g/km THC 2.0 g/km CO .15 g/km NOx

These certified tests show a nearly 80% reduction of HC's and CO across the board and a gain of 11mpg all while achieving EURO III emissions validation. This also shows we are way ahead of current EPA/ARB compliance and the answer to at least one European bike manufactures certification issues with just a 40mm SC. NOx was a little higher than the catalyst equipped system and is typical of high vaporization that creates a hotter burn, but still well within numbers. This may seem like not too big of a deal at first glance but consider there is no tradeoff in sacrificing fuel economy for emissions and eliminating costly catalysts. Did I mention we also saw an over 10% gain in HP? I have the dyno HP chart but it's on the SuperFlow at the lab. I will post it later. We've had to install a heated line needed for our emissions analyzers to complete the 2t emissions work so not able to pull numbers yet What we do know and is widely testified to is that we are making more power with less fuel, no spooge and reports of up to doubling fuel economy at race speeds. We claim a typical gain of 30% in fuel economy while testing and have extrapolated that the emissions reductions should be nearing 50% reductions in HC's and 25-30% in particulates which are normally commensurate to these types of emissions reduction. Less fuel, less pollution. Not to intentionally pull anyone away from here, but 100's of pages of this posted on KTMTalk, GASGas forums and so on with a lot of testimony, good and bad, along with the some of the fuel economy reports I'm referencing here. Anyway we would be happy to discuss this more as we begin those tests.

A carb isnt going to prevent short-circuting of fuel out the exhaust. thats where the majority of 2-cycle emmisions come from. DI like the e-tec injects fuel when the combusion chamber is closed and it cant escape. carbs cant do that. They cant stratify a charge either.

The SmartCarb of course cannot stop the air/fuel charge from short circuiting out the exhaust port.

I believe what's not widely understood is that short circuiting of the air/fuel charge, in a modern crankcase scavenged two stroke, is really a minor part of the overall emissions problem, especially in light of very effective variable exhaust ports/chambers and modern pipe technology. A simple drive by understanding of the amount of power a current high performance two strokes would reveal that they have very very good volumetric efficiency, some stock engines approaching 125-120% VE. These are obviously supercharged efficiencies and are due to sophisticated exhaust systems/power valves. Tuned pipes have been around along time, but modern tuning has broadened the torque output over a much longer curve. Hands down the bigger contributor to hydrocarbon emissions in a current 2t comes from the squish/quench area of the cylinder head, which by design traps large boundary layers of raw fuel. These boundary layers of liquid fuel remain after combustion (also remaining on the piston crown), remaining unburned they eventually find their way out the tailpipe and as such are the primary contributor to high HC release in modern two stroke engines. Engineers often refer to these squish/quench areas as surface area to volume ratios. A conventional modern two stroke squish/quench band comprises nearly 50% of the bore diameter and can contain upwards of 15-20% of the total trapped charge. The area of course is designed to accomplish two objectives.

1) To "squish" the mixture into the combustion chamber as near to the spark plug as it can get; also providing mixture motion to further homogenate the charge for a fast rate of burn, this is he reason we have set squish velocities we strive for when changing stroke or playing with fuels, compression, etc.

2) More importantly the area serves to trap raw fuel that is utilized to provide combustion control thereby preventing detonation and/or pre-ignition. Known as "quench", this trapped fuel is cooled by the adjacent metal surfaces adheres in layers and avoids combustion. Consequently this fuel winds up going out the exhaust unburned as the engine is operated.

In a Direct Injected engine it's necessary to incorporate both the injector and the spark plug into the cylinder head, requiring the combustion chamber to have a very high surface to volume ratio and in this situation large trapped boundary layers of fuel are again allowed to build, continuing to contribute to high HC emissions even though short-circuiting during the intake cycle was avoided. I'm not saying an E-TEC isn't a two stroke marvel and stratified direct injection is not working. In our world we have to continue to look beyond what is perceived, to what is real and the evidence is there, quench cooling is a problem; agencies no doubt will continue their pursuit of ever more stringent emissions reductions and fuel economy increases must continue, so for sure no stone will be left unturned.

Not sure how just the claim of finer atomization will change much. Sure like to see it. especially when the fuel gets 'beat around' quite alot between the carb and the spark plug.

Not so much beat around as picking up ALOT of heat. Finely atomized fuel (and oil) with a much greater surface area does a better job of wicking heat out of the engine and utilizing this heat to further vaporize the fuel. This is another reason a wet-flow system is appreciably advantageous over a dry flow DFI system. Corey

It is truly amazing...

It is truly amazing...