G

gspaulding

Member

backcountryislife

Wow, you've got some serious piston detonation going on there

Wow, you've got some serious piston detonation going on there

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

backcountryislife

Wow, you've got some serious piston detonation going on there

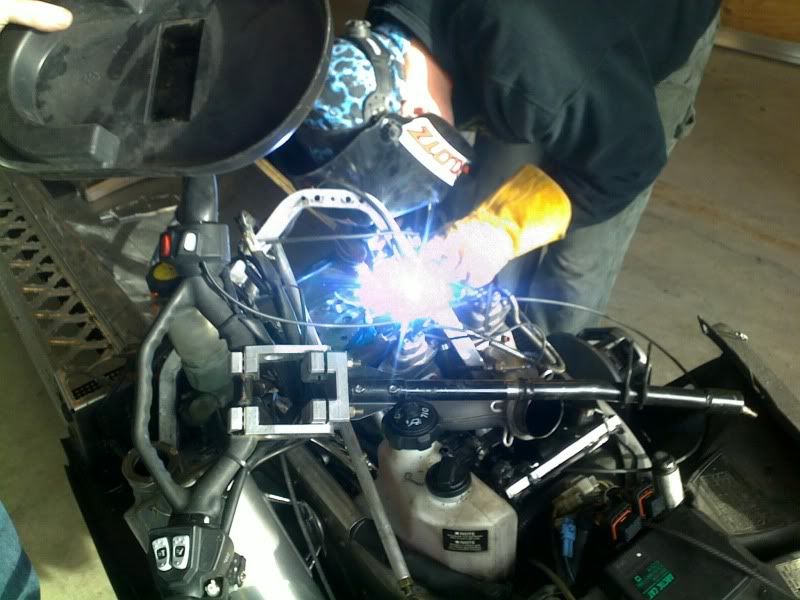

Here is my fix, thanks to some fab help from TurboMatt. Hope she holds up! It is 1/8 inch 6061 plate.

X2.does this happen to all the m8's? did they do anything to the 2011's?

I just posted a thread about a repair kit that I designed for this problem, it has been working awesome, started doing them last season. Look under Arctic Cat M-Series or use key words crack or bulkhead.

Here are the pics.