OK wise lifelong Ski-Doo owners, school me...

Last time I road my 850 I felt a lot of paddle slap coming from the tunnel, so I guessed that it was simply time for the first track tension adjustment towards the end of the break in period.

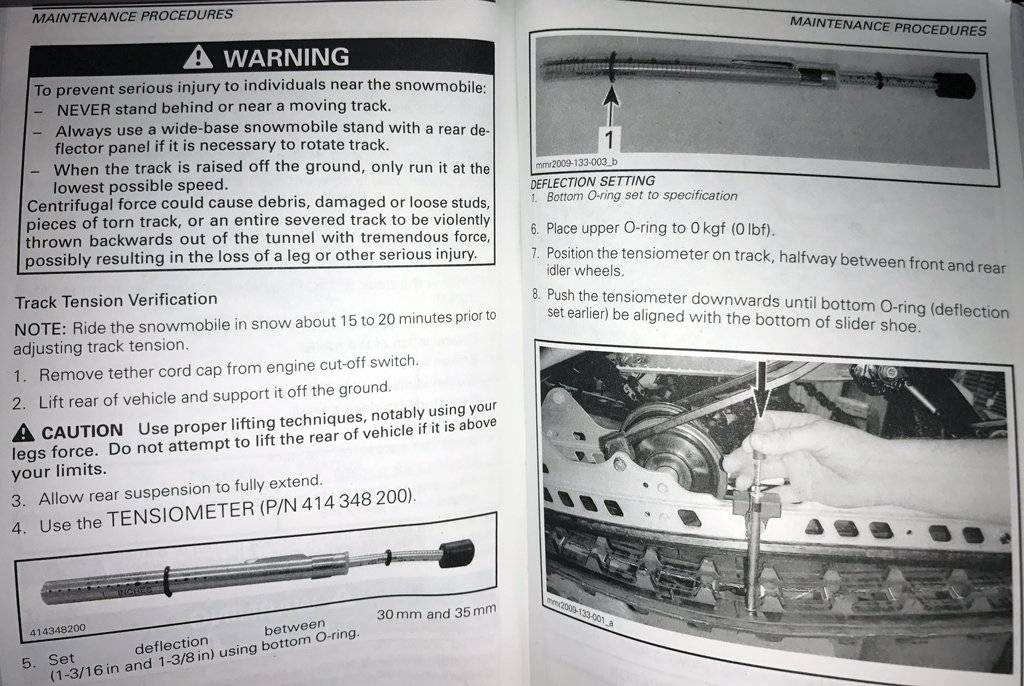

Whipped out my handy dandy Ski-Doo owners manual and read this..

Just so happens that I have that tool on hand as I had to use it to keep my supercharger drive belt dialed on my Nytro a couple years back.

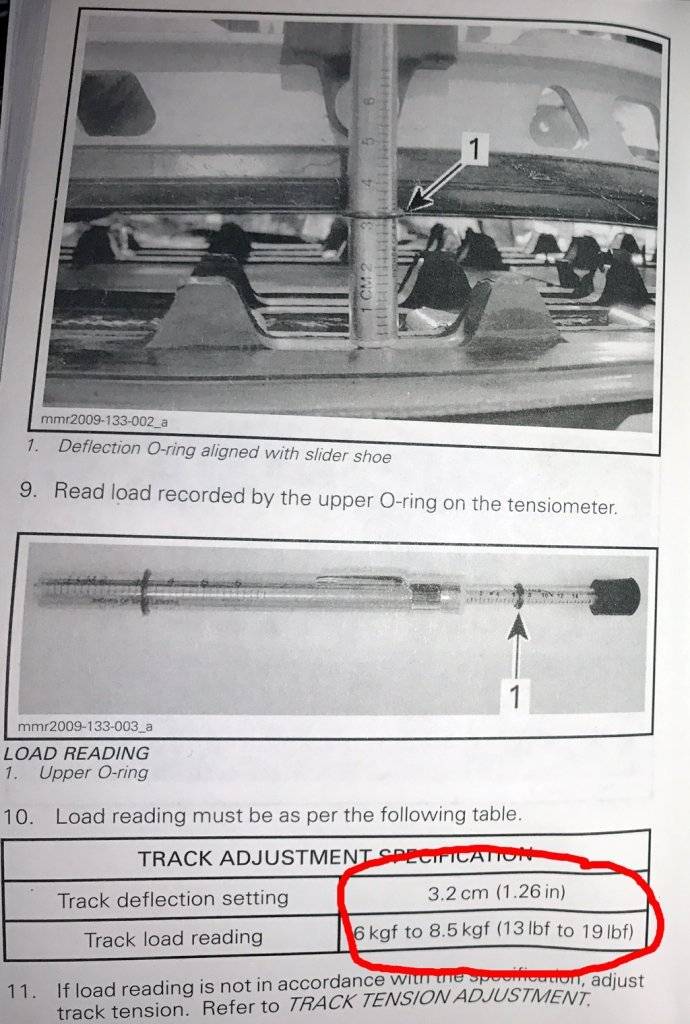

Book says I need 16lbs at 1.25 inches of deflection.

Lifted the sled up on the floor jack, checked current tension and it was WAY lose by comparison. So I released the main axle nuts, adjusted the tension bolts, rechecked the track tension to make sure it was IN SPEC then re-torqued the axle nuts, confirmed alignment and called it good.

Note: this seemed CRAZY TIGHT to me, but I am certain the track was tensioned exactly to book specifications...

Next day.

Spent the whole day riding all over Mt. Jefferson in Island Park.

Sled ran great.

No issues at all during the mountain riding.

At the end of the day we leave the mountain and take a long trashed forest service road all the way out. Towards the end of many miles of constant whoops on a never groomed trail the sled starts to ratchet for the first time.

The final stretch of the ride back to the cabin is open flat meadow.

The farther I go the worse the ratcheting.

About 3 miles across the meadow I give up as the sled is ratcheting 80% of the time and I am thinking I am just trashing the drivers.

Stopped multiple times to check track tension, and it seemed TIGHT.

Axle nuts appear tight

Adjustment bolts are tight

No signed of axle slippage or movement forward allowing the track to go lose.

Tomorrow the sled will go in for a checkup at my local dealer as the head mechanic is a personal friend and I will have a definitive answer in short order.

But I am curious, what do you think I did wrong?

Last time I road my 850 I felt a lot of paddle slap coming from the tunnel, so I guessed that it was simply time for the first track tension adjustment towards the end of the break in period.

Whipped out my handy dandy Ski-Doo owners manual and read this..

Just so happens that I have that tool on hand as I had to use it to keep my supercharger drive belt dialed on my Nytro a couple years back.

Book says I need 16lbs at 1.25 inches of deflection.

Lifted the sled up on the floor jack, checked current tension and it was WAY lose by comparison. So I released the main axle nuts, adjusted the tension bolts, rechecked the track tension to make sure it was IN SPEC then re-torqued the axle nuts, confirmed alignment and called it good.

Note: this seemed CRAZY TIGHT to me, but I am certain the track was tensioned exactly to book specifications...

Next day.

Spent the whole day riding all over Mt. Jefferson in Island Park.

Sled ran great.

No issues at all during the mountain riding.

At the end of the day we leave the mountain and take a long trashed forest service road all the way out. Towards the end of many miles of constant whoops on a never groomed trail the sled starts to ratchet for the first time.

The final stretch of the ride back to the cabin is open flat meadow.

The farther I go the worse the ratcheting.

About 3 miles across the meadow I give up as the sled is ratcheting 80% of the time and I am thinking I am just trashing the drivers.

Stopped multiple times to check track tension, and it seemed TIGHT.

Axle nuts appear tight

Adjustment bolts are tight

No signed of axle slippage or movement forward allowing the track to go lose.

Tomorrow the sled will go in for a checkup at my local dealer as the head mechanic is a personal friend and I will have a definitive answer in short order.

But I am curious, what do you think I did wrong?

Last edited by a moderator: