The snowmobile engine. Without it, your sled is just a toboggan-a really big and heavy toboggan.

You can live, if you have to, with a crappy suspension or bad seat or handlebars that don't quite fit your riding style.

But if your snowmobile engine is on the fritz or just isn't getting the job done, well, that can really ruin a ride. Or a season.

As much as the rest of the snowmobile has changed over the past decade, the snowmobile engine itself has undergone greater change. We would like to think these changes would have happened as a natural process of each manufacturer's R&D and that many of the changes we see today are driven by each company's quest to put their best foot forward, so to speak, in the industry. And we do believe that to some degree.

However, the truth of the matter is the U.S. Environmental Protection Agency and its proposed regulation of emissions probably has more to do with engine development in the past several years than anything else.

Regardless of the reasons, though, today's snowmobiles sport some awesome technology, especially in a sport as relatively small as snowmobiling.

Each snowmobile manufacturer has brought something to the table when it comes to engine technology. Fuel injection, liquid-cooled engines, RER, altitude compensation systems, heated carbs, 4-stroke engines-the list goes on.

However, as snowmobilers have painfully learned over the past few years, technology does not come cheap. While new suspensions, trick skis, fancy shocks, redesigned chassis all have a price, it all pales in comparison to the costs associated with developing new engine technology.

"Regulatory action taking place by our government is helping drive the price of snowmobiles," Ed Klim, president of the International Snowmobile Manufacturers Association, said. "It's expensive to build new engines."

You can't argue with cleaner engines. So far, from as near as we can tell, the only downside to all this attention to emissions is the cost. Horsepower really hasn't suffered much. But the cost of making those new engines so that they meet the EPA regulations is, well . how many ways can you say painful?

Each manufacturer has carved out its niche in engine technology. Yamaha, which continues to build its engines in Japan, has gone all 4-stroke. Polaris, which announced in mid-May it was moving its engine production facilities from Wisconsin to Mexico, offers some 4-stroke options but still mostly uses 2-strokes with Cleanfire Injection. Polaris calls the move to Mexico a "realignment" and expects to have a new plant in place by the first half of 2011.

Interestingly enough, Arctic Cat this summer announced it's going to start building its own engines in the United States, breaking its long time association with Japan-based Suzuki. Cat will begin manufacturing its own snowmobile engines in St. Cloud, MN, after the 2014 model year. Cat also offers some pretty stout 4-stroke engines but the majority of its sleds feature 2-strokes with batteryless EFI.

If you read the comment by Chris Twomey, president and CEO of Cat, in the Fronts & Forecasts section, about engines and why Arctic Cat is moving engine production to the United States, it seems obvious Cat wants to be able to better and more quickly control engine development in the face of government regulations. Cat has been manufacturing its ATV engines in St. Cloud since 2007.

As for Ski-Doo, it builds its engines in Austria at the company-owned Rotax factory. It offers a mix of 4- and 2-stroke engines, including a new offering for 2011, the Rotax 600 ACE, a 4-stroke with about 60 hp. E-Tec technology drives most of Ski-Doo's 2-stroke engines, with an 800cc offering this year.

Following is a look at each of the Big Four's engines and highlights of some of each manufacturer's biggest accomplishments and contributions to the sport of snowmobiling. And maybe, if they were in a good mood, what we might expect in the future.

Arctic Cat: 2012 And Beyond

Here's the skinny . Again

By Mark Bourbeau

For some sledders out there, this might be redundant information on the subject of snowmobile engines, but just in case you haven't paid much attention to it, the U.S. Environmental Protection Agency (EPA) is systematically clamping down on snowmobile emissions with another deadline looming for the 2012 model year.

For some sledders out there, this might be redundant information on the subject of snowmobile engines, but just in case you haven't paid much attention to it, the U.S. Environmental Protection Agency (EPA) is systematically clamping down on snowmobile emissions with another deadline looming for the 2012 model year.

Because of the looming EPA regs, there has been a smattering of rumors floating around in the industry that Arctic Cat's engines, currently manufactured by Suzuki in Japan, won't be compliant.

Hogwash, say Arctic Cat officials.

"Arctic Cat's motor plan is compliant for 2012," John Tranby, marketing manager for Arctic Cat, said.

The EPA emission requirement program for snowmobiles and other small engines was initiated for the 2006 model year and was set up as a three-phase implementation of emissions reduction on the amount of unburned hydrocarbons (HC) and carbon monoxide (CO) on snowmobiles sold in the United States.

Phase I (2006-2009) required 30 percent less HC and CO, phase II (2010-2011) required 50 percent less for HC and 30 percent less for CO, and now, phase III (2012) will require 50 percent less for both HC and CO.

Meeting these numbers is based upon a fleet average format, meaning that no manufacturer can exclude any model and/or motor technology. However, it also means that a "cleaner" engine could offset some "dirty" engines. The baseline for these numbers was an industry average derived by using existing models (pre 2006) from each brand. These baseline figures are 150 grams per kilowatt/hour for HC and 400 grams per kilowatt/hour for CO. While those numbers are firm, as you can guess with the federal government, it's not quite that simple. And to try and explain all the intricacies here would be even less simple. One thing we will point out is that snowmobiles must meet these standards over their "full useful life," according to the EPA. The EPA states, "The minimum useful life is 8,000 kilometers (4,800 miles), 400 hours of engine operation or five calendar years, whichever comes first."

No one will argue that the EPA's progressive program has had a noticeable impact on the reduction of snowmobile emissions, as well as the amount of fuel consumed by these newer machines. It has been estimated by some prognosticators that the fuel savings alone (not including lubricating oil) will amount to approximately 730 million gallons by 2012.

Plan on digging deeper into your pockets though. There is a price to be paid for this clean technology as the yearly purchase price increase of new sleds continues to rise-especially since 2005-to compensate for the additional investment being made from the manufacturers.

The interesting component of this scenario is that 4-stroke motors, including Cat's, are typically able to deliver significantly lower HC levels than a 2-stroke motor, while the 2-stroke is proven to do slightly better at emitting lower CO levels than the 4-stroke.

This will force your manufacturer of choice, including Arctic Cat, to pick their poison wisely.

GRILL TIME WITH GLEN

Even though we are knee deep in this emissions techno mumbo-jumbo, coupled with the fact that these ever-tightening regs aren't going to fade away into the sunset any time soon (or at all), along with the additional fact that the manufacturers are in the 11th hour to meet the 2012 EPA mandated emissions requirements, we are still excited to find out what's new in the engine department at Cat. So we did our best to pursue what information we could wring out of the all-knowing sources.

This last spring, ArcticInsider.com interviewed Arctic Cat engineering guru Glen Martin on the topic of engines and Cat was nice enough to share the questions and answers with us. Not so ironic is that our questions regarding engines were on the same track as ArcticInsider.com, so rather than do everything in double or triplicate, we were given permission to rerun the entire interview. There is no question that Martin knows his stuff as emissions manager at Arctic Cat, a position he has held for nearly two years. Previous to his job at Cat, Martin performed similar duties for companies such as Indmar, Big Dog motorcycles and MerCruiser.

HERE IS THE INTERVIEW:

ArcticInsider: What is the next phase in snowmobile emissions requirements per the Environmental Protection Agency (EPA) and how does it compare to the current phase?

Glen Martin: We're currently in Phase II and we'll move into Phase III for the 2012 snowmobile season. If a person looks at it straightforward, the difference is that maximum carbon monoxide (CO) emissions drop from 275 grams (per kilowatt/hour) to 200 grams. There is a nice calculation that allows the CO to increase to a maximum of 275 as the HC decreases from 75. If you work with this everyday it is easy and if you don't, it's like learning a second language. Phase III is a huge change and we have to push technology to another level.

AI: What does this mean with regards to the current crop of engines Arctic Cat has available to consumers?

GM: Without getting too technical and not divulging our future product plan, it means the 2-stroke engines that we currently sell must get cleaner. That means using our existing technology in new and better ways and/or incorporating new technology.

Our Z1 and Z1 Turbo 4-stroke engines currently meet the 2012 Phase III requirement and in fact earn emissions credits.

It is important to note the Arctic Cat emissions group's mission statement: To deliver the highest-efficiency, horsepower-improving emissions system that our customer doesn't think about.

What we mean by "doesn't think about," is that our emissions systems must work in such a way that they have no negative impact on the customer experience (Industry-Leading Horsepower, World's Fastest Snowmobiles, etc.) Arctic Cat will always strive to achieve our emissions goals without sacrificing performance.

AI: Are there other new EPA mandated rules that will come into play in the future, like the gas tank permeability rule?

GM: The EPA typically revisits the rules for an industry every five years. If that remains their time frame, then 2016 would be the earliest we'd see a new set of retail requirements. However, considering the improvements that have been made and the current economic conditions, we are hopeful that there will be a period of stability in regards to emissions levels.

AI: Even in 2012, snowmobile emissions will remain fleet-average, correct?

GM: Correct. That makes it possible for some engines to be higher than the fleet-average emissions levels provided that they are offset by a sufficient number of snowmobiles that emit below the standards.

Like it did with the CAFE (Corporate Average Fuel Economy) standards for automobiles and recreational marine products, the EPA adopted ABT (Averaging, Banking and Trading) provisions when it wrote the rules for the snowmobile industry.

AI: What does the 2012 Phase III requirement mean for fan-cooled 2-strokes?

GM: Sorry, but answering that question would essentially be commenting on future products, which we can't do.

AI: No problem. We're not trying to get you to divulge what engines we'll see in 2012 and beyond, only trying to learn if 2-stroke fan-cooled engines could be part of the mix. We personally see that type of engine as an ideal value-priced mill.

GM: I understand and I appreciate fan-cooled 2-strokes for the same reason.

AI: Again, not trying to peer into future products but, in your opinion, what does the future hold for 4-stroke vs. 2-stroke engines?

GM: Other industries might give us a glimpse into the future, in particular the marine industry, because engines in that application are used in high-load, high-speed conditions. There, both 2-stroke and 4-stroke engines are still viable.

In the European auto industry, which is another application that sees high speeds and loads compared to the U.S., they are achieving emissions requirements through the use of catalysts.

One other point is this: Snowmobilers shouldn't be scared. I have faith in technology and ingenuity to solve the challenges and hurdles of engine emissions, and to do so in a way that adheres to our mission statement.

LETTING THE CAT OUT OF THE BAG

Prior to this interview, Arctic Cat was pretty quiet as to their battle plan to cope with the final stage of this program, leaving the media and aficionados alike to ponder the idea that the sky is falling in on Cat. After reading Martin's comments, it's obvious Cat is in this for the long haul and will have its ducks rowed out in time for D-Day.

That was further substantiated by the summer announcement that Cat is moving its engine production in-house, meaning no more Suzuki, as Minnesota-based Cat will be building its engines in St. Cloud, MN. See Fronts & Forecasts in this issue for more information on that announcement.

With the release of a new 800 H.O. a couple of seasons ago, Cat stays on track with 2-stroke technology as that engine continues to be one of the strongest on snow.

Pure Polaris Power

A Brief History Of The RMK's Powerplant

By Ryan Harris

Known through the 80s and 90s for the sweet tone of its Japanese-built triple-cylinder Fuji engines, Polaris has been on a different path for the last 10 years. Polaris has offered 11 different displacement engines between 440 and 900 since the 90s. That is a ton of engine technology.

Known through the 80s and 90s for the sweet tone of its Japanese-built triple-cylinder Fuji engines, Polaris has been on a different path for the last 10 years. Polaris has offered 11 different displacement engines between 440 and 900 since the 90s. That is a ton of engine technology.

But who are we kidding? The biggest news of 2011 is Polaris' Pro RMK 800. The mountain market is focused-for better or worse-on the 800s. Has been for. well, about a decade. About the time Polaris first released the 800 RMK in 2000.

So, how about a trip through the years on the heads of the Polaris 800 powerplant.

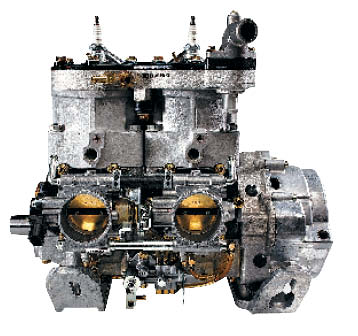

LIBERTY 800 TWIN

For model year 2000 Polaris brought two 800 engine options: one a triple-cylinder, triple-exhaust lake racer (XCR 800) and the other a lightweight 800 twin (800 RMK). The triple-triple XCR had peak power, but the twin cylinder RMK was light and torquey. It was a great power plant for mountain riding and ushered in a new class segment for mountain sleds. The lightweight twin featured case-reed design with twin 40mm Mikuni flat-slide carburetors (remember those?). And if you think we've advanced immensely, the 2000 800 RMK also had a low-octane fuel switch. The 2011 has a similar ethanol switch. There was no high-tech altitude compensation system, though Polaris had experimented with electronic fuel injection systems previously. The flat-slide Mikuni carbs offered a very broad range of altitude operating specs. One thing the 2000 800 RMK had (along with the 600 and 700 RMKs) that we haven't seen for a while is perimeter cooling, where hot coolant was routed through the running board edge rolls where it melted ice buildup as it cooled. Oh, and if modern sleds had the 2000 RMK's running boards, they wouldn't be modern.

LIBERTY 800 V.E.S. TWIN

Polaris' next leap forward came two years later, when engineers improved the lightweight 800 twin by adding Variable Exhaust System (V.E.S.). Polaris engineers told us that adding exhaust port height control improves low-end throttle response and cleans up exhaust emissions. The V.E.S. engine had a 12-horsepower increase over the non-V.E.S. engine at 6,000 rpm and a four percent increase in peak horsepower. V.E.S. also offered a claimed 20 percent improvement in fuel economy.

On model year 2003 sleds, Polaris further enhanced the 800 twin with Grafal-coated pistons and a decompression hole in the cylinder to reduce pull starting effort. Polaris would later remove the decompression hole (maybe if you're riding an 800, you should be man enough to start it?). Grafal is a thin coating on the piston skirt intended to reduce friction, mainly during the engine break-in process, since the coating eventually wears off.

The 2003 RMK 800 models also offered something new: Polaris Electronic Reverse Control. PERC is a licensed technology from BRP's Rotax Engine Reverse (RER). When activated, PERC (and RER) would stall the engine and cause ignition combustion at a point that would reverse the engine's directional rotation. The clutches would spin in reverse, eliminating the need and weight of a mechanical gear set and handle. It's technology that is still with Polaris on the 2011 sleds. The advancements on the V.E.S. 800 twin also trickled down to the 700 and 600 V.E.S. engines.

Another key technological advancement in 2003: Detonation Elimination Technology (DET), which is a detonation control system that retards timing three degrees if detonation occurs. Polaris engineers explained that these engines are designed and calibrated specifically for high grade fuels to give customers the maximum power. The detonation sensing technology protects the engine in the event that lower grade fuels are used.

LIBERTY 900 CLEANFIRE INJECTION

The 800 V.E.S. twin survived through the 2005 model year, although it was overshadowed by Polaris' new baby, the 900 Liberty.

(And now we pause for a moment of awkward silence.)

On paper, the new 900 mil was a technological wonder. It was the first Cleanfire Injection (CFI) engine Polaris had ever offered. It had solenoid-controlled variable exhaust valves with titanium valves. It featured both the intake and the exhaust on the forward side of the engine, so that the big twin could sit lower in the chassis. The 900 had a long stroke design for maximum torque, 51 mm throttle bodies and new W reed cage assemblies. The 900-in the new IQ chassis-shared DET, PERC, Grafal-coated pistons and perimeter cooling with the 800 RMK.

Engineers at Polaris say CFI technology gave their engines elevation and temperature compensation, reduced emissions, improved throttle response and fuel economy and offered easier starting.

The 2005 900 RMK paved the way for the 2006 700 RMK with the Cleanfire 700 twin (which was actually a 755cc twin. awk-ward). While those two motors were short-lived, they were responsible for ushering in the current generation of fuel-injected Polaris engines. All Polaris needed was to refine the engine design and mate it to a no-nonsense chassis. And that is exactly what it did with the 2007 Polaris Dragon RMK.

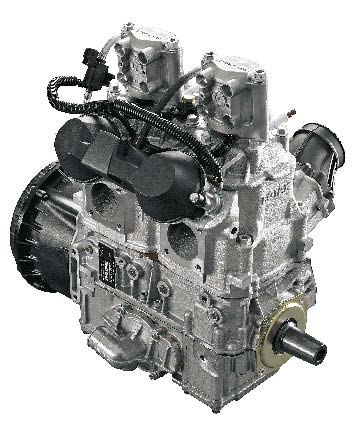

LIBERTY 700 H.O. CLEANFIRE INJECTION

Polaris came out swinging in 2007 with another new CFI engine. Though this one was a true 700. Rather than engineer down from the 900 twin, Polaris engineered up from the proven 600 HO Cleanfire engine. Built on the 600's small-block bottom end and cylinder design, the new 700 HO shared the same bore and stroke as the previous 700 CFI engine version. The new 700 HO twin used four injectors: two in the crankcase and two in the cylinders. The design was clean (emissions were really driving engine design at the time) and was the best-running Cleanfire engine Polaris had produced to date. In fact, the Dragon RMK was SnoWest's top pick for mountain sleds that year and the machine won our Deep Powder Challenge, beating out the other 800s for deep-snow performance and fun-to-ride style.

The 700 HO CFI engine hit its peak horsepower at 8,250 rpm, making a claimed 140 hp. Polaris focused on the exhaust system as well, using a new manufacturing process and new material thicknesses to create a new lightweight exhaust system. The entire RMK package lost 25 lbs.

LIBERTY 800 H.O. CFI 4-INJECTOR

Proving that the western mountain market is incredibly valuable, Polaris offered a new 800 HO CFI twin exclusively for the 2008 Dragon RMK. The mono-block twin built on the success of the 700 HO CFI, making strong power with crisp response. The 800 HO Cleanfire engine was a hit with western riders. So much so that Polaris dropped the 700 HO CFI engine (and models) from the lineup in 2010.

The 800 HO CFI twin received minor improvements for 2009 and again in 2010. Most of the attention was placed on fuel mapping.

LIBERTY 800 H.O. CFI 2-INJECTOR

For 2011, the 800 HO CFI engine returns, although with more of a facelift than a simple improvement.

Notable changes to the 2011 800 CFI twin include: 2-injector design for more consistent mapping, better throttle response and more mid-range; new fuel rail; new engine management system; new fuel injectors; new port design, linked oil pump and new exhaust system.

These major enhancements give the 2011's 800 twin more mid- to upper-mid range power compared to the 4-injector engine in the `08-`10 RMKs.

The new engine management system addresses ignition system issues that have impacted select 800 RMK models over the past two years. The new system includes electrical components being sourced from a different manufacturer. A new ECU, regulator and stator are part of a new management system design that eliminates some components. The 2011 800 RMK's electrical system is similar to that of the proven 600 Rush.

Ethanol has become the thorn in the bear's paw, causing engineers headaches over how to create a fuel injection map that works with 91 octane gasoline while also tolerating blends of up to 10 percent ethanol. (This drops one component of the fuel's octane rating while the combined method still nets a higher octane rating. High performance small engines do not respond well to this and have a tendency to detonate on ethanol blends.)

To combat this growing gasoline trend, Polaris says the 2-injector design is more tolerant of fuel blend changes. Engineers have also added a manual plug, which is a 2-pole resistor that allows you to preset the sled's fuel management system for the times when you know you're getting straight premium unleaded and the times when you're not so sure.

Emissions technology is percieved as a negative sometimes, but it's interesting to note that, compared to its first domestic Liberty 800 twin, the current 2011 800 engine is about 50 percent cleaner and 12 percent lighter (according to Polaris) and produces much better performance across a broader range of conditions.

LIBERTY . AND BEYOND?

Where will Polaris engine technology go in the future? We're looking at model year 2012 as a year where Polaris will likely make some engine changes in the lineup to meet 2012 EPA emissions guidelines. Whether that will directly impact the 800 RMK is tough to know at this point.

Polaris stated to us that while long-term plans for snowmobile engines are obviously confidential, "Our priority is to deliver durable engines with cleaner emissions and outstanding performance. Our customers expect our sleds to be king in the mountains and we will be relentless in exceeding their expectations."

Additionally, it was announced early in 2010 that Polaris had purchased Swissauto Powersports. If you're up on your engine manufacturer names, you'll know that the high-performance 4-stroke Weber engines of the FST and other models were developed by Swissauto. Polaris said in a press release that the acquisition "will further strengthen Polaris' global engine and vehicle design capability." But RMK fans need not read too much into that; Swissauto's technology lends itself to four-strokes and turbocharged engines and will likely have a stronger presence in Polaris' motorcycle, ATV and side-by-side segments.

Oh, and don't hold your breath for a new 800 triple anytime soon, either.

Ski-Doo Engines: Leading Edge Of Technology

Seven Big Ski-Soo Engine Breakthroughs

By Lane Lindstrom

Night and day. That's a pretty telling contrast but it doesn't do justice if we were to try and compare J.A. Bombardier's use of a Kohler 4-stroke engine in his first over-the-snow vehicle sled in 1959 to today's E-Tec technology, which has to be considered the leading edge of engine technology in the snowmobile industry.

Night and day. That's a pretty telling contrast but it doesn't do justice if we were to try and compare J.A. Bombardier's use of a Kohler 4-stroke engine in his first over-the-snow vehicle sled in 1959 to today's E-Tec technology, which has to be considered the leading edge of engine technology in the snowmobile industry.

And it goes a lot deeper than simply comparing the Kohler's paltry 7 hp to the E-Tec 800R's 155 hp. The E-Tec is dripping with all sorts of technology, technology that helps it score big points with the EPA as the federal government imposes even more emissions restrictions on snowmobile engines in the coming years.

The E-Tec engine, built by Ski-Doo-owned Rotax, is just the latest in a string of snowmobile industry firsts when it comes to engine technology. We tried to narrow that list down to a half dozen but that was difficult. So we settled on seven.

High Altitude Compensator (HAC) - Back in 1994, Ski-Doo devised this system which compensated for altitude and temperature, two really big variables in the mountains. HAC was introduced on the 1994 Ski-Doo Summit, the first snowmobile dedicated solely to mountain riding and the two millionth snowmobile produced by Bombardier. HAC was described as a system that countered the carburetion richness that can occur because of altitude and temperature changes commonly found in mountain riding. A diaphragm in the HAC would flex in response to air pressure changes (remember air gets thinner as you climb and visa versa), mixing more or less fuel with air in the carburetor. Essentially HAC was a mechanical process controlled by pressure.

"The HAC was significant because it was the first altitude compensating system offered in the mountains," explained Dominique Godbout, director of marketing for Ski-Doo and Sea-Doo. "Customers no longer had to jet for the day's ride or suffer at one altitude to optimize another altitude."

HAC was replaced by an electronic system in 1998 when the Digital Performance Management system was introduced on the Summit 670x. The DPM uses electronic sensors to monitor temperature and altitude and then feed the information to the ECU, which, using solenoids, adjusts pressure on the fuel in the carburetor's float bowl to create an ideal air/fuel mixture. A natural byproduct of such systems as the DPM was improved fuel economy because the engine is running optimally instead of poorly where more fuel would be used.

"The DPM refined the concepts of HAC to provide better fuel/air ratios for all altitudes and temperatures without having to re-jet," Godbout said. "The customer could now ride at any altitude and get clean engine calibration without touching anything. It applied to all altitudes, not just the mountains. It also provided better fuel mileage and performance everyday at every location."

Rotary Valves - "It was important for Rotax/Ski-Doo to show the kind of horsepower that is available in 2-stroke designs with a controlled intake," Godbout said of rotary valves, another Ski-Doo exclusive. "These valves allowed timing of the fuel charge independent of the piston position with no blow back through the intake and it effectively filled the crankcase with fuel charge. The benefit was high performance per cc (volumetric efficiency) and tunable valve timing (more than 180 degrees possible for inlet opening timing) so that engines could be tuned for high rpm, high horsepower or more for torque, acceleration and fuel economy."

Rotary valves were first introduced on the Blizzard 440 Racer back in 1972.

Rotax Adjustable Variable Exhaust (RAVE) - RAVE valves, which debuted on the Mach 1 583 in 1989, enabled sledders to have what Ski-Doo called at the time "two engines in one." One was when the valves were closed, creating small exhaust ports for idling and cruising while the other was when the RAVE valves were opened, making large exhaust ports for higher performance and top end speeds. Thus, smaller exhaust ports produce the best torque, fuel economy and emissions while larger exhaust ports produce the best power.

The original RAVE valves were opened with exhaust pressure and timing determined by the valve's spring pressure.

When Ski-Doo unleashed its new 800R engine on the 2007 Summit, it incorporated new 3-D RAVE exhaust valves. The 3-D comprised: three-opening positions; the valves control three exhaust port openings per cylinder; and the 3-D mapping that determines the valves' operation. In the 800R, the engine uses crankcase pressure for the opening force and the ECM and solenoids for the timing. The 3-D RAVE added an intermediate opening position for better performance and fuel economy at speeds Ski-Doo estimated most people ride (about 25-60 mph). Engineers accomplished the additional opening position by splitting the single valve/guillotine into two.

Commenting on the RAVE, Godbout said, "This provided a very simple and effective way to broaden the torque of a 2-stroke engine, by varying the size of the exhaust port. Designs no longer had to compromise between good low end pulling power with high fuel economy, versus high horsepower, top-end performance. The benefit was the consumer got great performance on both acceleration and top end and an improvement in fuel mileage."

RER - RER is so widely accepted in the snowmobile industry most folks don't even remember what the letters stand for: Rotax Electronic Reverse. This is one slick piece of engineering. Sledders who used to pull/drag/tug their sleds around when the got in a tight spot (or wanted to unload from a trailer) could now push a button and go in reverse. We never knew what we were missing until RER was featured on Ski-Doo sleds beginning with the Tundra R and Touring SLE in 1998. When you push the RER button, the engine stalls, changes its directional rotation and the sled goes in reverse. All this with no weight penalty.

Other snowmobile manufacturers followed suit after the turn of the century as Ski-Doo licensed its technology and sold it to others. However, you didn't see widespread use of RER on Ski-Doo's mountain models until after the 2002 and 2003 model years.

"This is now the standard for two stroke reverse systems industry wide," Godbout said. "It's significant as it reduced weight and complexity in a reverse system for snowmobiles. Customers of high performance sleds like Summits and MXZs now have reverse without added weight or clunky systems that can add to maintenance."

Semi-Direct Injection (SDI) - It was Rotax 2-Tec semi-direct injection that allowed all Ski-Doo 600 and 800 engines with that technology to meet EPA regs in 2006, which now seems like ancient history as 2012 regulations stare th e industry in the face. The 2-Tec 800 SDI debuted in 2003 and the 600 H.O. SDI in 2004. Those SDI engines featured two injectors per cylinder (using a unique dual sequential firing pattern), knock sensors and engine calibration and exhaust valves that were electronically controlled. That eliminated the need for a choke and cleaned up the emissions, by as much as 50 percent, according to Ski-Doo. Fuel and oil consumption also improved by 25 percent because of a cleaner burn.

Godbout gave more detail on SDI. "SDI took electronic fuel injection to the next level by injecting the fuel in the transfer port late in the induction cycle to scavenge more with pure air and eliminate some raw hydrocarbons from escaping the combustion process. Fuel mileage increased along with performance gains."

The 600 E-TEC replaced the 600 SDI in 2009 in what really is cutting edge technology for the snowmobile industry. E-TEC, which utilizes direct injection technology, wasn't new but it was new to the industry when Ski-Doo incorporated that know-how into a snowmobile engine.

BRP first developed the E-TEC's direct injection two-stroke technology in Evinrude outboard engines. That technology won the Clear Air Technology Excellence Award from the EPA. At the time Ski-Doo raved about the E-Tec's fuel economy, which was claimed at 21 mpg while using 15 percent less fuel than the SDI. Ski-Doo made similar claims when the 800 E-Tec (19 mpg and 264 miles per quart of oil) was introduced on select 2011 models.

That's about 30 percent better on the oil consumption compared to an SDI for a trail rider. Rotax was able to accomplish that feat due to the precision of the system's electronic oil pump and computer mapping. But since more mountain testing on production motors last spring, Ski-Doo is backing down a bit on the claims for the Summit. Fuel mileage will be 12 percent better and oil economy will remain the same as a PowerTEK 800R. The change is attributed to the test cycle of a typical mountain rider where they tend to be at WOT much more often than a trail rider.

Direct injection is just that-direct. The fuel is directly injected into the cylinder head under extremely high pressures. There is a fuel pump in the fuel tank that brings fuel to the injectors. Some of that fuel isn't being burned but is used to cool down the system, specifically the ECM, and then is recycled back to the fuel tank.

The injectors are positioned adjacent to the spark plug in the cylinder head. Injecting fuel into the combustion chamber as the piston is compressing requires high pressure, which is delivered by the E-TEC electronic injectors at about 500 psi. That pressure helps atomize the fuel.

There are two basic modes in an E-TEC engine: Stratified and Homogeneous. The Stratified mode is when the engine is first started up and running at idle. Idle is about 1200 rpm. Ski-Doo and Evinrude engineers explained that in this Stratified mode, a tight cone of fuel is injected into the cylinder, using one-third of the fuel than a carbureted enging would and injected right before the spark. The fuel combusts before it gets a chance to disperse. All that means is during that mode the 600 uses the fuel of a 200cc engine at idle. It's also at idle that the machine sounds like a four-stroke, very quiet.

It's at about 3500 rpm that the Homogeneous mode kicks in. Here that tight cone of fuel is injected into the cylinder where it mixes with air for a split second before being combusted by the spark. Hence the name Homogeneous or mixed.

There is some added weight with the top injectors, about a pound or two on each side. But, because the E-TEC is batteryless, unlike the SDI system it replaces, you save the weight of the battery and it's almost a wash.

"E-TEC brought direct injection technology to the snowmobile world," explained Godbout. "Direct injection 2-strokes allow us to build high performance, fuel efficient and low emission snowmobiles without a significant weight penalty. Direct injection eliminates almost any fuel from escaping the combustion process. In order to meet current EPA requirements straight up without using credits or corporate averaging, direct injection was required. Customers get the lightweight and high horsepower they want for easy handling in the steep and deep with virtually no smoke or smell and easy throttle pull. Boondockers especially appreciate the benefits."

For now-and at least the immediate future-Ski-Doo is on the right track with its E-TEC technology. The combination of low emissions, good fuel mileage and great power is a winning one.

Of course that doesn't mean Ski-Doo isn't working on refining the E-TEC and/or looking at new technology. No manufacturer usually sits still, especially Ski-Doo.

"Engine technology is driven by market demands, social responsibility and regulatory issues," Godbout said. "If an emerging trend is seen we try to meet that need or help create the demand with a technology we see that has real benefits for our customer."

Leading The Way In 4-Stroke Technology

Looking inside Yamaha engines

By Steve Janes

For five out of the past six years, Yamaha engineers have developed a new, high-tech and reliable 4-stroke snowmobile engine, each designed by a highly skilled team with more than 50 years of engine-building experience.

For five out of the past six years, Yamaha engineers have developed a new, high-tech and reliable 4-stroke snowmobile engine, each designed by a highly skilled team with more than 50 years of engine-building experience.

With a lot of R&D in all aspects of Yamaha's motorized recreation departments, Yamaha engineers have access to a lot of data collected on 4-stroke engine design and development. Since the motorcycle segment at Yamaha is the largest, a lot of the R&D discoveries have transformed into the development of snowmobile engines.

"Technology is more often shared from motorcycle than ATV," James Vizanko, assistant testing department manager and snowmobile engineer at Yamaha, said. "Head design, valve design, FI technology has been shared among the Yamaha product groups." However, he pointed out that technology from the snowmobile design will also get applied back to the ATV and motorcycle engine design.

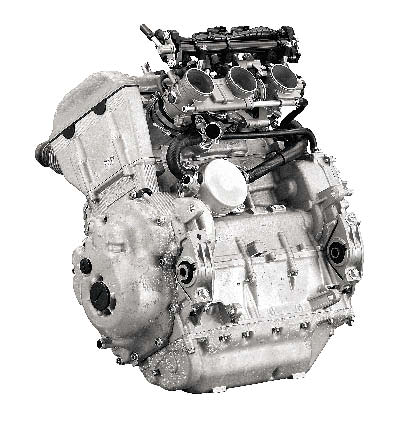

Presently in the snowmobile line Yamaha offers four 4-stroke engine packages.

"The 120 and 130 engine packages are very similar-in-line three-cylinder designs," Vizanko explained. "The 80 is a two-cylinder parallel twin design and the four-cylinder is a parallel four." The 80 and 150 engines are five-valve, while the 120 and 130 engines are four-valve.

Vizanko said all engines use dry sump technology and similar ignition systems (Transition Control Ignition). Although all feature an open loop fuel system, the intake and exhaust designs are specifically tuned for each engine.

APEX

On the Apex models, Yamaha engineers designed the high-performance Genesis 150FI engine as strong as possible and as lightweight as possible, using a magnesium valve cover and a titanium exhaust pipe.

"Not only is the material exotic," explains Vizanko, "Yamaha has some pretty unique processes for making snowmobile engine parts related to casting and hardening. A rare earth magneto is now the norm used for maximum electric power generation."

Vizanko said the lightweight engine design technology starts by balancing the internal forces from the reciprocation and rotating masses along with the combustion forces. The pistons and connection rods are the reciprocating forces and the crank shaft and balance shafts are the rotating masses. The lighter your piston, wrist pin and connection rod, the less dead weight you need to attach to the crankshaft.

"Once the total internal forces are known, the engine case support structure can be optimized to accommodate these forces," Vizanko explained. "This accommodation occurs by defining the correct stiffness needed and matching material properties to obtain a high stiffness-to-weight ratio."

The core concept is to create a broad power curve (that's easy to clutch to) with excellent acceleration corner to corner. An advanced fuel injection system gives the engine "right-now" performance.

Riders feel the benefits of the design process when they grab the throttle and experience instantaneous acceleration.

Although the 4-cylinder Genesis 4-stroke engine casting remains the same, the valve timing, intake and exhaust tracts, airbox and exhaust pipes are all recalibrated for optimum midrange torque output as well as an overall top-end gain. The 4-hole injector on the throttle body creates a spray of finely atomized fuel, with droplets of just tenths of a micron in size. The spray is aimed directly at the intake valve skirt for maximum efficiency and performance. The engine utilizes the pressure waves in the longer intake tubes and in the airbox to boost airflow and maximize high rpm performance.

The distance between the throttle valve and intake valve has been redesigned for optimum fuel delivery. Yamaha-exclusive EXUP valve technology controls the exhaust pressure waves for optimum intake and exhaust efficiency, delivering unmatched overall performance with more midrange torque.

"Similar to motorcycles, the important task of EXUP is to keep optimum tuned length of the exhaust system across the entire window of rpm," explained Vizanko. "Without EXUP technology, the tuning of the exhaust system is somewhat predetermined. You have to balance the performance gains at certain rpm with the dips which accommodate these gains."

Generally the stronger you try and gain in one area of the rpm curve, the harder the hit is in another area-common laws of wave propagation for conventional fixed exhaust systems. "The EXUP technology allows us to knock down the wall and recover these torque dips, resulting in more power throughout all rpm," he explained.

Additionally, the exhaust pipes have been enlarged to 38 mm from 35 mm for added exhaust pressure wave efficiency. The new Top Performance Genesis 4-Stroke engine features the unique Engine Braking Reduction System that allows a small amount of air to pass through the fuel injection system when the throttle is released, giving riders more of a "coast" sensation.

NYTRO

The new Genesis 130FI triple is the latest fast-revving, high-torque powerplant to hit the snow.

"The focus for this snowmobile engine is to make a maximum torque that can respond quickly," Vizanko explained. "The torque is what gives you the pull feeling on acceleration."

Vizanko said 4-stroke engines from Yamaha are not typical in other industries. "The 4-stroke engine used in high performance motorsports applications must have a lightweight high performance characteristic to meet the abuse of consumers pushing them to the limits. Throttle response is determined by lightweight moving parts and sophisticated FI technology. Both are very important to the delivery of the desired package."

The Genesis 130FI shares the same advanced fuel injection system as its 80 and 150 horsepower-class cousins, giving razor-sharp throttle response, excellent fuel economy and dependable cold starting.

It boasts a sizable performance gain over the Genesis 120. That gain can be credited to a slightly larger displacement, 1050cc 3-cylinder design and lightweight crank technology.

The high performance engine uses Yamaha's advanced fuel injection system to control fuel flow to the engine, which provides spot-on performance and throttle response as a result.

"Fuel injection itself is not for performance," Vizanko explained. "Engine performance comes from its dimensions and dynamics."

For Yamaha engineers, engine tuning is developed on the dyno and in the field. "The FI field calibration is fixed within six months after performance is fixed in dyno," he said. "The basic system came from motorcycle development, but some parts were modified for snowmobiles."

Yamaha first developed the FI control system for the Apex. Since then every model starts at that point and receives its own final adjustments.

The patented rear exit exhaust design maximizes horsepower by using a straight exhaust pipe design.

"The shape of the pipe is not as important as the length, although straight is the most efficient design," Vizanko said. This is Yamaha's latest technology-balancing performance, cost and thermal management requirements.

Also, it reduces the amount of under-hood heat produced and distributes weight to contribute to the excellent balance of the sled. The forced air radiator ducting airflow design pulls fresh air in from around the headlight and forces it through the radiator fins for high cooling capacity, resulting in consistent engine performance even in low-snow conditions.

VECTOR

The smooth-running 120 horsepower-class Genesis 120 triple has proven itself one of the most reliable engines with its broad power curve and excellent fuel economy. The Genesis 120 keeps pulling hard once it gets into the peak performance zone.

This is the next generation of trail cruising powerplants. The mid-performance engine delivers simplicity, fuel economy and great performance. The advanced fuel injection system automatically keeps it running at maximum output and fuel efficiency for the conditions. It also offers the Engine Braking Reduction System, which, as previously mentioned, lets the sled freewheel when you let off the throttle.

The mid-performance engine uses Yamaha's advanced fuel injection system to control fuel flow to the engine. Consumers will enjoy the engine's spot-on performance and throttle response as a result of the advanced electronic fuel injection system.

The exhaust is routed out the back of the sled in order to optimize and maximize airflow through the engine. The tuned system is specifically engineered to produce the mid-performance engine's broad powerband and also to help keep the sled in balance.

The RS Vector GT's airflow design pulls fresh air in from around the headlight and forces it through the radiator fins for high cooling capacity, resulting in consistent engine performance even in low-snow conditions.

PHAZER

The lightweight, sporty 80 horsepower-class Genesis 80FI powers the fun Phazer sleds. Its high-tech, fuel injection system gathers and analyzes data about the ambient conditions as well as from the engine to maintain optimum fuel flow. The fuel injection, combined with the Genesis 80FI's lightweight, counterbalanced crank, gives it razor-sharp throttle response. A knock sensor helps protect the engine when you can't find 91 octane fuel.

Lightweight, dependable and fun, the sport performance engine's high tech design puts down 80 horsepower-class performance on the trail and off. Powering in the distinctive Phazer family of sleds, this 2-cylinder engine is quick-revving and very torquey for sporty acceleration. The advanced fuel injection system automatically keeps it running at maximum output and fuel efficiency for the conditions.

The sport performance engine uses an advanced fuel injection system to control fuel flow to the engine. Consumers will enjoy the engine's spot-on performance and throttle response as a result of the advanced electronic fuel injection system.

The sport performance engine's crankshaft is designed to be lightweight, responsive and durable. The lightweight, counterbalanced crankshaft delivers super-crisp throttle response and quick acceleration. It also helps mitigate the vibration inherent in a 2-cylinder engine.

The exhaust from the sport performance engine is routed out the rear of the sled, similar to the other Genesis 4-stroke engine packages. The rear exiting exhaust design serves three purposes. First, it keeps the exhaust heat out of the engine bay to allow a super-compact design. Second, it allows the engine to breathe more efficiently through a cooled exhaust pipe. Finally, it helps to balance the overall sled package, giving the Phazer RTX its amazingly nimble handling.

In order to generate consistently-strong engine performance, all Genesis 80FI sleds feature a small radiator on the right hand side of the engine cab and a front extrusion. The use of a small radiator improves the sled's cooling system function, which means greater engine durability. It also enhances the sled's handling by relocating the mass of a rear heat exchanger up to the central portion of the sled.

The 2011 Phazer RTX is fitted with an oil pressure sensing system. If the oil pressure drops while riding, the ignition and fuel supply is controlled to limit the engine's rpm and reduce the load on the engine. If necessary the system will stop the engine.

INCREASING 4-STROKE POWER

Yamaha has earned a reputation of providing an engine platform ideal for creating additional power.

"From a natural aspirated state, the Yamaha engine is tuned for performance, reliability, response and sound," Vizanko said. "Many tuners like the Yamaha engine because of the structure design and FI fuel system in place. This allows aftermarket tuners the opportunity to ring out the system without much worry."

However, Vizanko said there are limitations in every design.

"The engine team at Yamaha Motor LTD is always investing in research and development," Vizanko said. "The IC engine has been around for a long time and it is hard to determine what is radical any more. The relationships with R1 and YZF and GP are very strong." And Vizanko confirms that the "pool of technology" at Yamaha is far from empty.

So the next big question is: How does the EPA influence engine design in the snowmobile industry?

"EPA has and will continue to have significant influence on engine design in the snowmobile industry," Vizanko said. "Yamaha has looked at the complete proposal of `current' EPA requirements through 2012 Phase III standards. These requirements no doubt have made an impact on engine design and the entire snowmobile product plan."

The EPA's influence has created more costs associated with the production process, which in turn are passed on to the consumer. But it has also advanced fuel system technology.

"Snowmobile engines continue to make more horsepower, burn less fuel doing it and last longer than ever before," Vizanko explained.