K

Klimbing Kitty

Well-known member

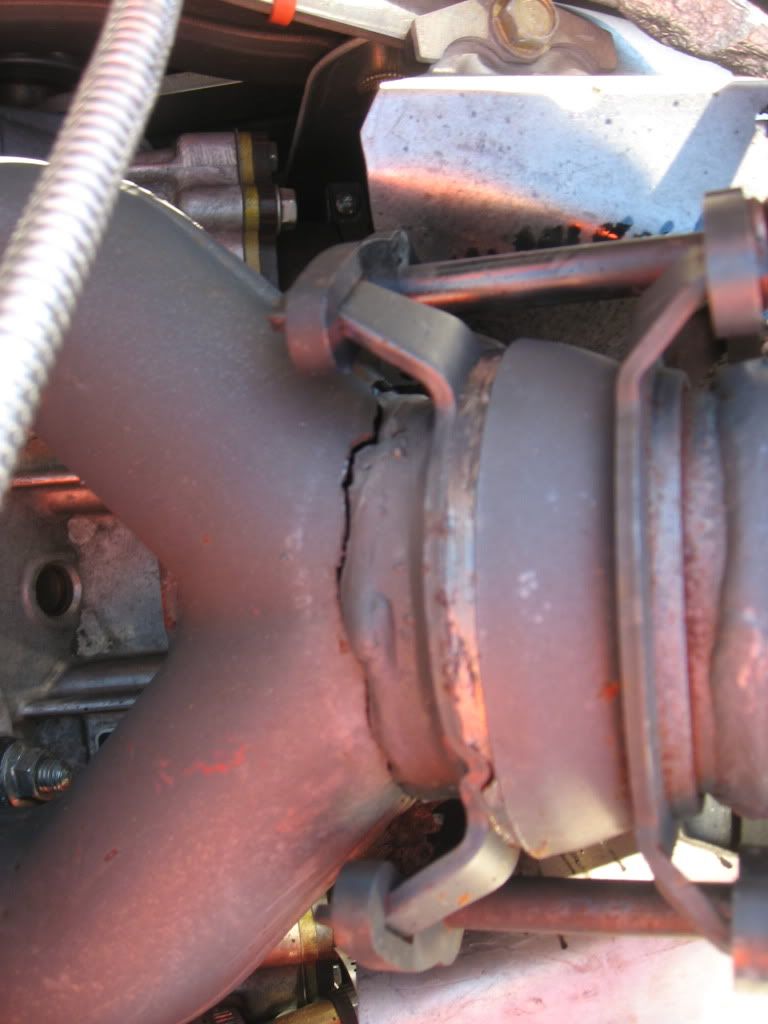

Now is it common for Y pipe to crack? Is it because of the solid 2 spring loaded clamp mount, or just a weak factory pipe? Cat has none in stock for a couple of weeks, and a 2009 will not fit a 2010. Is the D&D turbo Y-pipe stronger? or any other aftermarket?

Cheers