Looking at powder coating a arms ,spindles, rails, runnin.g boards and front bumper. Are bonded parts ok? Will it actually ruin the heat treated parts? Which parts are heat treated? Thanks

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which 2013 pro parts are safe to powder coat?

- Thread starter Allterrain

- Start date

Looking at powder coating a arms ,spindles, rails, runnin.g boards and front bumper. Are bonded parts ok? Will it actually ruin the heat treated parts? Which parts are heat treated? Thanks

I personally will not powder coat anything but that is just my opinion, Most of those that do powder coat never keep the sled long enough to see the downfalls of powder coat. So put a bullet in the cylinder and spin it and see if you get lucky?

"Safe" is a relative word..

If you have a generic quality powdercoater that only uses 400 degree powders and bakes the snot out of parts put in the oven with fence rails from highway commission... none of the parts you've listed are safe.

Polaris Paints the rails on the 2014's for a reason... the 7129 alloy will become weaker in the baking process...

For me... Paint the rails, or hardcoat type III, running boards too... I'm not too keen on anything to do with the bonded arms that involves heat... you would need to fixture them or risk breaking the bond.... Keep them as spares and buy some aftermarket arms...coat them whatever color you want... or sell the originals on ebay for $300.

Find a painter in your area... and get them all painted... you can do the clean/prep and the priming yourself to save some $$... Will be a push for cost. Plus you can touch up the paint if it gets scratched. ....LOTS of color choices there.

For paint... I'm really liking the durability of the U-Tech single stage (no clear coat) paints... finding it is more durable than most of the

If you have a generic quality powdercoater that only uses 400 degree powders and bakes the snot out of parts put in the oven with fence rails from highway commission... none of the parts you've listed are safe.

Polaris Paints the rails on the 2014's for a reason... the 7129 alloy will become weaker in the baking process...

For me... Paint the rails, or hardcoat type III, running boards too... I'm not too keen on anything to do with the bonded arms that involves heat... you would need to fixture them or risk breaking the bond.... Keep them as spares and buy some aftermarket arms...coat them whatever color you want... or sell the originals on ebay for $300.

Find a painter in your area... and get them all painted... you can do the clean/prep and the priming yourself to save some $$... Will be a push for cost. Plus you can touch up the paint if it gets scratched. ....LOTS of color choices there.

For paint... I'm really liking the durability of the U-Tech single stage (no clear coat) paints... finding it is more durable than most of the

Did spindles, a arms, running boards, bumpers & rails on two of our sleds at the beginning of the season. Have about 1000 hard miles on both of them & no issues. We even chemically dipped them to strip them. Maybe were lucky? Just use a smart Powdercoater & don't worry. Personally I think if your glue is gonna fail it will either way.

Some powder coaters do a "burn off" to clean parts before baking... that will, with out question ruin the parts... Some do a bake cycle of 30min at 400 degrees F... that will ruin a rail.. I've seen this personally.

Some powder coaters know how to clean, prep and coat high tech alumium alloy... but they are in the minority of powdercoaters out there... and can be trusted to follow through with what they say they'll do.

350 degrees max for 20 min MAX... and you are still walking the thin line.

I've seen some pretty expenseve truck/car rims destroyed by powdercoating.

If you don't know & trust your powder coater... you are taking a risk IMO.

.

Some powder coaters know how to clean, prep and coat high tech alumium alloy... but they are in the minority of powdercoaters out there... and can be trusted to follow through with what they say they'll do.

350 degrees max for 20 min MAX... and you are still walking the thin line.

I've seen some pretty expenseve truck/car rims destroyed by powdercoating.

If you don't know & trust your powder coater... you are taking a risk IMO.

.

……………………….

350 degrees max for 20 min MAX... and you are still walking the thin line.

.. you are taking a risk IMO. .

I guarantee any time above 300 degrees will remove the temper and render it into cooked spaghetti. I do this all the time at work to bend the heat treated alloys. I use one of two easy indicators; the carbon from an acetylene torch (before turning the oxygen on), or a Sharpie marker. Both burn off at about 300 degrees and when the black has disappeared and the aluminum color has just returned (instantaneously- no hold time required) the temper is out and you can complete your bends without breaking alloys such as 6061-T6 where as it will fracture otherwise. My experience with alloys and my passion for metallurgy is why I will not Powder Coat anything. Additionally the coating will fail and looks like crap, especially with the aluminum being without it's heat treatment to maintain it's strength and shape.

So again it is up to you, and the previous analogy applies. Do you ride hard enough to see the consequences of your choices or do you ride like a girl? (No offense intended to those that are actually of the female gender)

What mountainhorse and loud handle are saying is they have no personal experience with powder coating any parts on a pro rmk. I'd take their advice accordingly.

Powdercoated sled

Oh yeah icr

Your old powdercoated pro is still getting ridden like a stolen mule.

Holding up great.

Oh yeah icr

Your old powdercoated pro is still getting ridden like a stolen mule.

Holding up great.

Oh yeah icr

Your old powdercoated pro is still getting ridden like a stolen mule.

Holding up great.

Good to hear, the new one is problem free as well, never would've thought that possible if I believed half of what I read here.

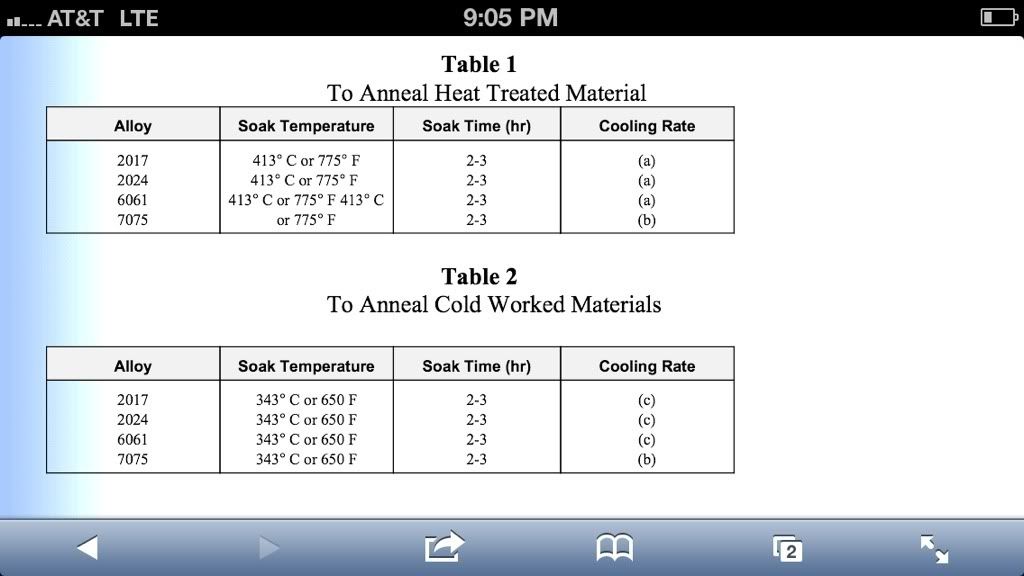

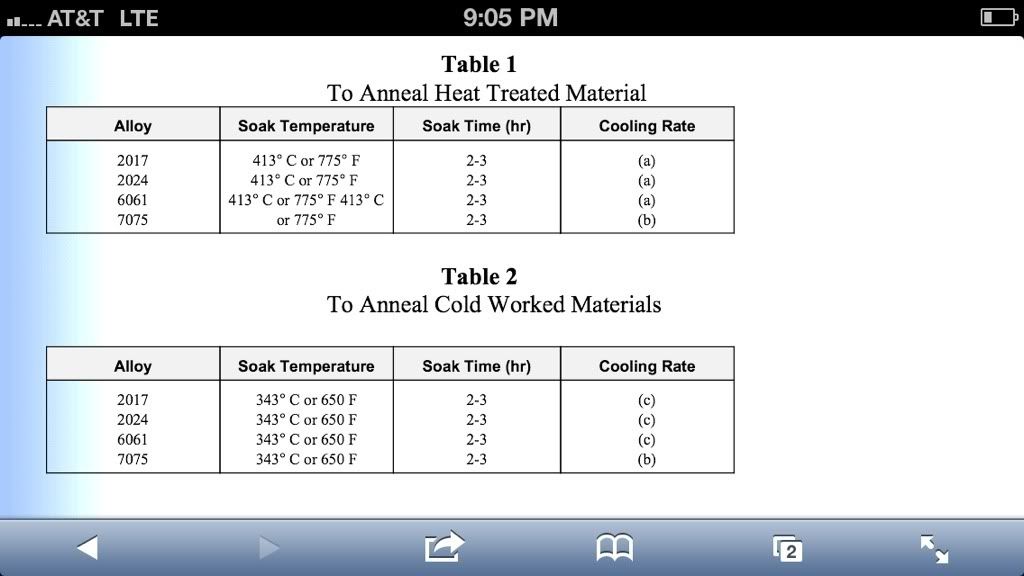

Here's a chart to clear up some confusion about annealing temps on this thread. Powder coating is safe, if done properly. If your powder coated matches mountain horses description run. And as always folks, do your own research. Talk to your powder coated. Spend five minutes searching on google. Don't trust the inexperienced experts found here.

Last edited:

What mountainhorse and loud handle are saying is they have no personal experience with powder coating any parts on a pro rmk. I'd take their advice accordingly.

And your uncoated PRO chassis that I bought from you folded in half held up so well you want to encourage people to weaken them further?

My experience goes way beyond the PRO chassis. Metallurgy is Metallurgy, it doesn't matter what the alloys are used to construct. All I said was, If you exceed 300 degrees your ruining the structure of your sled or any thing else made from heat treated aluminum alloys. PERIOD!

If you want to powder the steel parts knock yourself out.

Good to hear, the new one is problem free as well, never would've thought that possible if I believed half of what I read here.

Here's a chart to clear up some confusion about annealing temps on this thread. Powder coating is safe, if done properly. If your powder coated matches mountain horses description run. And as always folks, do your own research. Talk to your powder coated. Spend five minutes searching on google. Don't trust the inexperienced experts found here.

That information is misleading at best, that is what is required to get it back to the zero temper state. BUT you lose the greatest majority of it's strength in the first 300 degrees. Zero temper is about as strong as cooked spaghetti and you surely don't want to go that far. You don't have to believe me, I told you what I know for fact and my conscience is clear. It is and always has been your choice.

And your uncoated PRO chassis that I bought from you folded in half held up so well you want to encourage people to weaken them further?

My experience goes way beyond the PRO chassis. Metallurgy is Metallurgy, it doesn't matter what the alloys are used to construct. All I said was, If you exceed 300 degrees your ruining the structure of your sled or any thing else made from heat treated aluminum alloys. PERIOD!

If you want to powder the steel parts knock yourself out.

That sled was jumped hard, landed on the bumper and flipped end over end. I'm not sure what that has to do with powder coating.

I've powder coated many sleds, including two pros, never had a failure because of it. That's my experience.

Or once you do this I can re-solution treat to "W" condition, hold on ice and re-straighten full lg. then age to either T6 or T73 if needed. Basically heat to 920*F and quench in a 2000 gal. tank within 3 sec. It will probably look like spaghetti noodle once it hits the water! untwist,straighten,untwist, restraighten, change the leading radius,even add a 2* bend to the back of the rail like the IQ models. Wouldn't this be a hoot! Mike

What education and/or experience do you have with materials?

To me you sound like you are scrambling at best to come up with a reason that your parts failed. I can run the analysis on a bar knapkin for you over a warm high life if you need validation. 400F will not do anything to the temper or strength of the material. Why yes I do have a materials and a mechanical engineering degree. Oh and yes I do submit to the FAA all procedures and practices of powder coating sensitive aircraft parts that I do at work. By the way it is an approved process by the FAA, state department and federal offices. It is also listed in the ASTM catolge. Please stop providing individuals with wrong information about powder coating because you had a bad experience.

Thanks in advance

To me you sound like you are scrambling at best to come up with a reason that your parts failed. I can run the analysis on a bar knapkin for you over a warm high life if you need validation. 400F will not do anything to the temper or strength of the material. Why yes I do have a materials and a mechanical engineering degree. Oh and yes I do submit to the FAA all procedures and practices of powder coating sensitive aircraft parts that I do at work. By the way it is an approved process by the FAA, state department and federal offices. It is also listed in the ASTM catolge. Please stop providing individuals with wrong information about powder coating because you had a bad experience.

Thanks in advance

What education and/or experience do you have with materials?

To me you sound like you are scrambling at best to come up with a reason that your parts failed. I can run the analysis on a bar knapkin for you over a warm high life if you need validation. 400F will not do anything to the temper or strength of the material. Why yes I do have a materials and a mechanical engineering degree. Oh and yes I do submit to the FAA all procedures and practices of powder coating sensitive aircraft parts that I do at work. By the way it is an approved process by the FAA, state department and federal offices. It is also listed in the ASTM catolge. Please stop providing individuals with wrong information about powder coating because you had a bad experience.

Thanks in advance

What air line do you work for? So I know not to fly on it anymore. My bias is not due to any failures or bad experiences. I just will not use it because I'm a purist and know what the potential loss of strength really amounts to. You can tout your education all you want but it is in error. I deal with a lot of government agencies at work also and the people who write that drivel are complete morons. Listen to "Experts" who are morons also, most of which can be proven impossible with grade school math. No engineering degree needed.

I will refrain from further posts in this thread. Do what you want.

If you live in Valdez you fly in aircraft I have coated parts for.

I might add I was a welder before school. 6g cert and continued on welding aircraft parts to put myself through school. So yes I can design it and I can also walk into the shop and build it I ve worked hard and long enough to have blood come from under my finger nails so I guess I am a little different engineer than your use to.

I might add I was a welder before school. 6g cert and continued on welding aircraft parts to put myself through school. So yes I can design it and I can also walk into the shop and build it I ve worked hard and long enough to have blood come from under my finger nails so I guess I am a little different engineer than your use to.

Last edited:

You guys sure are passionate about this... not sure if that is good or bad...(wink)

Icr... you obviously have a good powder coater... most are not set up to do it right nor take the time to do it right.

The most important part of my replies to your posts in the past is this:

The mfg of Polaris rails says do not bake the 7129 alloy... Polaris would p-coat the 2014 rails if it did not give them warranty issue potential... Painting is more expensive.

I haves seen many powder coated rails hold up... I've had them... and seen many other that did as well that had ZERO issue... but I've also seen MANY other that had bent rails because they lost their heat treat during the powder coat process.

I've also seen some full chassis that had ZERO issues and some that would bend pushing on the bumper... both after powder coating..

Depends on the materials used, cleaning process' and soak time. If parts are being used in an airplane that has FAA Certs... I'd wager that the Powder coater would need to be able to certify the work as well... that would, by default, be a good powdercoat shop.

According to my sources, the 5052H32 alloy used in the chassis can handle a bit more heat than the Rails... the castings... are ok to bake at reasonable heat/cycle times....

If you coat the entire chassis.. make sure it is supported well in the oven so that when the adhesive softens... it does not move... once cured it will have a stronger bond as long as it was not over baked... The downside is that the adhesive does loose some flexibility after the heating according to Lord Adhesives App engineers.

Here was my reply to ICR you a couple years back on the same subject.

This one came out well... baked at 350 using specific low temp powders ... which is what ICR said he used.

The previous one failed... which is how I ended up with an expensive learning curve.

If I were to do it again... I'd paint the chassis with U-Tech 3.8... more durable than the low temp powders and a push or less for the cost... prep time is the same.... I soda blast the chassis regardless of choice to powder coat or paint... best adhesion!!

To continue last years discussion

Icr... you obviously have a good powder coater... most are not set up to do it right nor take the time to do it right.

The most important part of my replies to your posts in the past is this:

"Good discussion and nice sled you have... you take pride in your work and I respect that."

The mfg of Polaris rails says do not bake the 7129 alloy... Polaris would p-coat the 2014 rails if it did not give them warranty issue potential... Painting is more expensive.

I haves seen many powder coated rails hold up... I've had them... and seen many other that did as well that had ZERO issue... but I've also seen MANY other that had bent rails because they lost their heat treat during the powder coat process.

I've also seen some full chassis that had ZERO issues and some that would bend pushing on the bumper... both after powder coating..

Depends on the materials used, cleaning process' and soak time. If parts are being used in an airplane that has FAA Certs... I'd wager that the Powder coater would need to be able to certify the work as well... that would, by default, be a good powdercoat shop.

According to my sources, the 5052H32 alloy used in the chassis can handle a bit more heat than the Rails... the castings... are ok to bake at reasonable heat/cycle times....

If you coat the entire chassis.. make sure it is supported well in the oven so that when the adhesive softens... it does not move... once cured it will have a stronger bond as long as it was not over baked... The downside is that the adhesive does loose some flexibility after the heating according to Lord Adhesives App engineers.

Here was my reply to ICR you a couple years back on the same subject.

As for the statement that I have no experience with powder coating the chassis on an RMK... not true.I'd also disregard mountainhorse's advice on the subject as he has no personal experience. I powdercoated my 'glued together' pro chassis and wouldn't hesitate to do it again.

The Acrylic adhesive is DESIGNED to release at typical powdercoat temps... not rocket science for the reasons "against".

icr... Glad yours came out.. but not responsible to claim that there are no concerns in the process.

Would I powder-coat a PRO RMK chassis ... absolutely not... But hey that is my take on it.

On top of that... the aluminum will "over age" and loose structural strength if the temp is even a bit too high... 400 degrees is the "danger zone" for most of the alloys used in the construction of that chassis. Unless you used low temp powders... your chassis is probably weaker from the process.

I do have experience with this... the weakening of aluminum chassis from powdercoating... had an IQ chassis that was powdercoated that failed because of the powdercoating process...

Many are already complaining about wrinkling their new pros from jumping or accidents etc... Why risk it??

The U-Tech paint is a substitute for Imron... super durable and definately affordable... at least as durable as 90% of the consumer available powders out there.

BTW... I dont have any personal experience in jumping off bridges either.

Thats my opinion... there are plenty of others out there too.

.

This one came out well... baked at 350 using specific low temp powders ... which is what ICR said he used.

The previous one failed... which is how I ended up with an expensive learning curve.

If I were to do it again... I'd paint the chassis with U-Tech 3.8... more durable than the low temp powders and a push or less for the cost... prep time is the same.... I soda blast the chassis regardless of choice to powder coat or paint... best adhesion!!

To continue last years discussion

icr is correct.. the bond will be strengthened slightly after heating... but the downside is that it will loose some of the flexibility according to the engineers at Lord.

This may or may not be an issue... if some 'give' is not needed in the joint.. then this will not be an issue.

icr obviously had a good powdercoater... which is what I said in the first post... I would NOT put MOST pow coat shops in the the "good" category... not many have experience with intricate structural assemblies like the PRO tunnel. Most of them do not carefully control bake temps, soak times, pre heat, or total bake times.

As a side note... don't coat (paint or powder) the heat exchangers inside the tunnel... You will absolutely loose cooling capacity if you do... I HAVE "been there, done that" .. The PRO already has a small cooling capacity in the tunnel.

Here is a quote from a post I made in the other thread in the link above

http://www.snowestonline.com/forum/showthread.php?t=236334

Mountainhorse:

ONLY the best powdercoaters with good holding fixtures and low temp powders with shorter bake times should even be considered...

More than the powder itself... having a powdercoater that you absolutely trust not to over temp or over bake (time) your aluminum parts is key.350 for 15 minutes, only thing that bent was the thin strip on the tunnel between the coolers.

.

My main concern is not simply with the adhesive... but the structural integrity of the chassis and the alloys it is made from.

Those alloys are identical in the PRO and IQ chassis.

Just talk to Mike "aksnowrider" and he can show you just where the chassis can have issues when pushed beyond normal use.

icr, Your pow coat shop is rare... you should feel lucky.

Have a look at that original post...

http://www.snowestonline.com/forum/showthread.php?t=236334

I didn't say it wasn't possible... I said to be careful and outlined, 14 months ago, the concerns that you addressed in using low temp powders and very short bake cycle times.

I stick to my recommendation against... I wouldn't trust a shop to to do the work the right way. Too many variables involved for my liking.

Like I said, your shop is rare... and that in itself is very cool!!

.

icr, I think we agree more than disagree.

Looks like you added some supplemental plates to the side of your tunnel?

With that freeride seat an the tunnel mods... I assume you do some hucking... more than my old body can handle.

Good discussion and nice sled you have... you take pride in your work and I respect that.

Title:

Unless you a very confident in the QC of your pow-coater of choice... think twice.

icr.... the two big things that you have going for you (strength wise) with your powdercoated tunnel assembly are:

1) You braced the chassis considerably in many ways.

2) You seem to have a good powdercoat shop that only used a 15 minute total bake cycle, no "burn off" cycle and max temp of 350 degrees f.

But to be fair... unless I'm mistaken, you have not powder-coated and used a stock chassis assembly (bulkhead/tunnel) that was not significantly reinforced??

For the average joe out there... be very careful when powdercoating an engineered aluminum structural assembly... IMO, there is a higher likelyhood of most people having a bad result rather than a good one.

...Which is why I recommend the urethane paint over the powder coat... It will be tougher than low temp powder as well. The U-Tech is a replacement for Imron and is very affordable.

.

Covered in another thread. http://www.snowestonline.com/forum/showthread.php?t=236334

If you are going to do it... take it to a body shop and use a high quality urethane paint like that used on fleet/commercial trucks... no clearcoat needed.

U-Tech 3.8 HSP paint. Base/Clear are a lot of effort that, IMO, are not needed on a sled... This stuff is tough as nails and is reparable if you scratch it deeply. On gloss jobs...you can sand and polish out scratches.

IMO... PERFECT paint for sleds... slightly flexible and durable.

I've used it on other equipment and my tool box... those take more abuse than my sled.

http://cdautopaint.com/index.php?option=com_content&view=article&id=61&Itemid=96

http://www.hotrodders.com/forum/u-tech-paint-192773.html

Last edited:

And on top of this... C'mon... lets be civil to each other here... We are all passionate about our sleds... and the work we do... no need not to be civil to each other!

Thanks for all the replies. After reading this and some other articles and others on the internet, I'll be going with spray on paint as I don't feel powder coating is worth the risk. Also this will allow me to paint my tunnel without stripping the entire sled!

Similar threads

- Replies

- 0

- Views

- 451

F

- Replies

- 8

- Views

- 2K

F

T

- Replies

- 1

- Views

- 2K

T