non ho cylinders would be a better choice of course for cooling wise and all, but if you tweak a cylinder your buying both... so i suppose ho can be nice for the fact of price that way

fuels wise to prevent deto, if your not already running something other than pump gas... av gas is a good way to go because its not much more expensive and puts you at 100 + its anti knock additives, i pay $1.70/L for av, race here with a deal runs me $3/L for 111 octane, But yes race fuel makes more hp as far as the fuel goes.... but it does cost a fair bit more,

and the aerocharger turbos, they are a great turbo for what they are...., so if it runs well for yeah then leave it unless your looking to make some big power... of which a bigger turbo would be needed, but im sure your well in the turbos efficiency range up to 8-10 pounds boost, beyond that it may become small

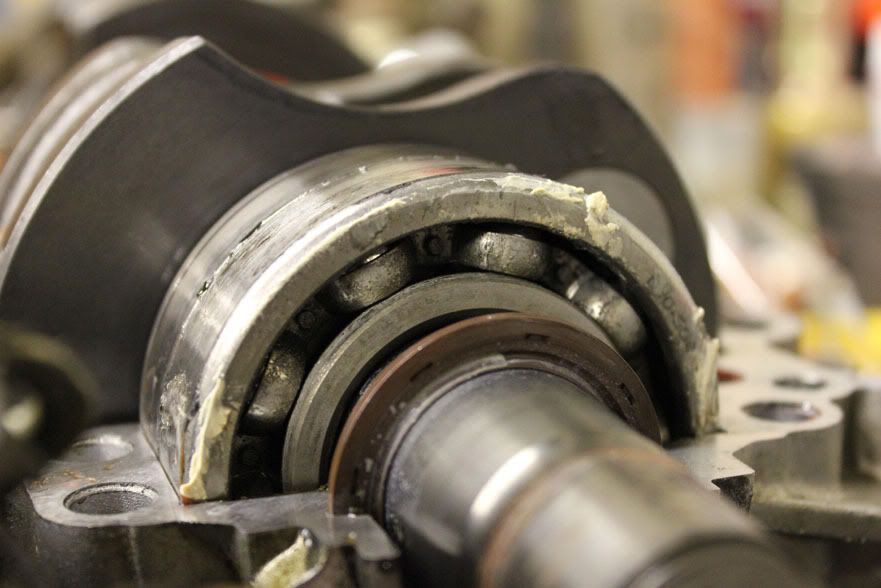

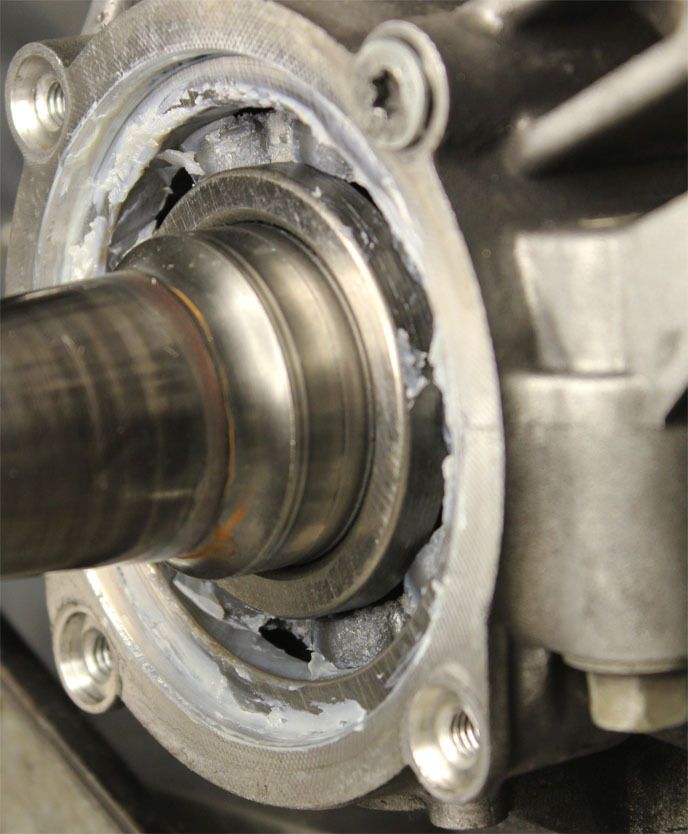

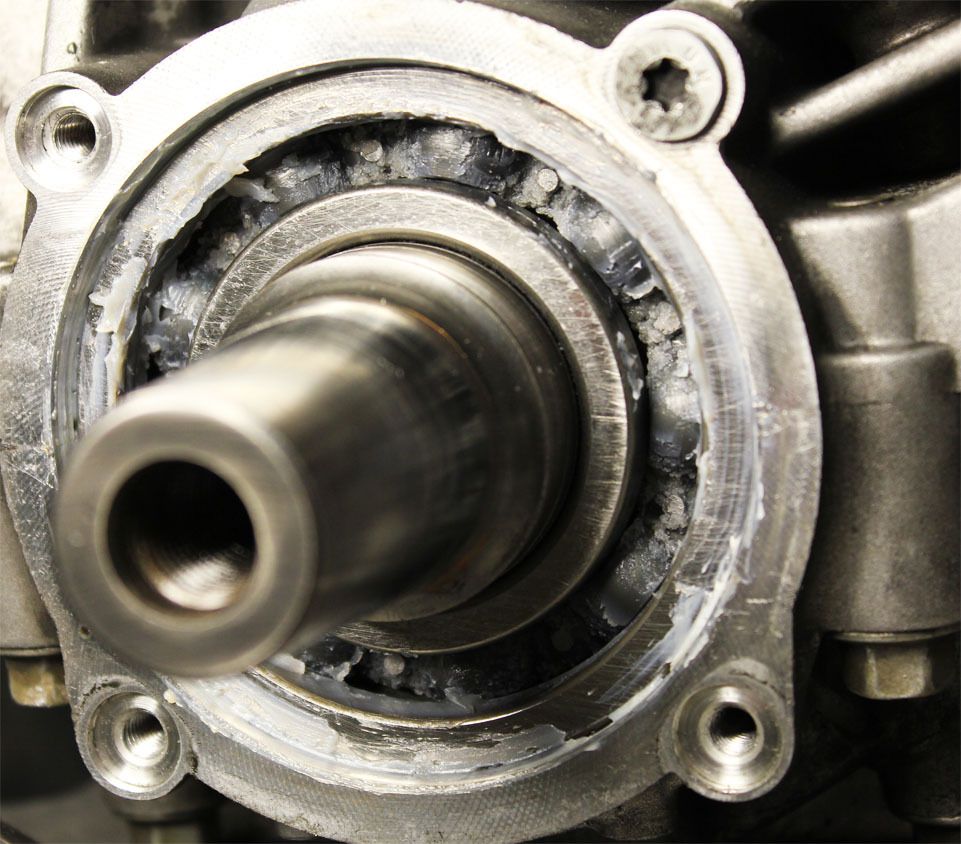

and sorry to see about your bearing there!, id give big john at sled head racing a call, good guy to deal with, will grease,true and what ever else the crank for you so you know its good when you drop it in, he does a ton of engine work too... big bores and alot more so he knows what hes doing

fuels wise to prevent deto, if your not already running something other than pump gas... av gas is a good way to go because its not much more expensive and puts you at 100 + its anti knock additives, i pay $1.70/L for av, race here with a deal runs me $3/L for 111 octane, But yes race fuel makes more hp as far as the fuel goes.... but it does cost a fair bit more,

and the aerocharger turbos, they are a great turbo for what they are...., so if it runs well for yeah then leave it unless your looking to make some big power... of which a bigger turbo would be needed, but im sure your well in the turbos efficiency range up to 8-10 pounds boost, beyond that it may become small

and sorry to see about your bearing there!, id give big john at sled head racing a call, good guy to deal with, will grease,true and what ever else the crank for you so you know its good when you drop it in, he does a ton of engine work too... big bores and alot more so he knows what hes doing