D

Danbot

Well-known member

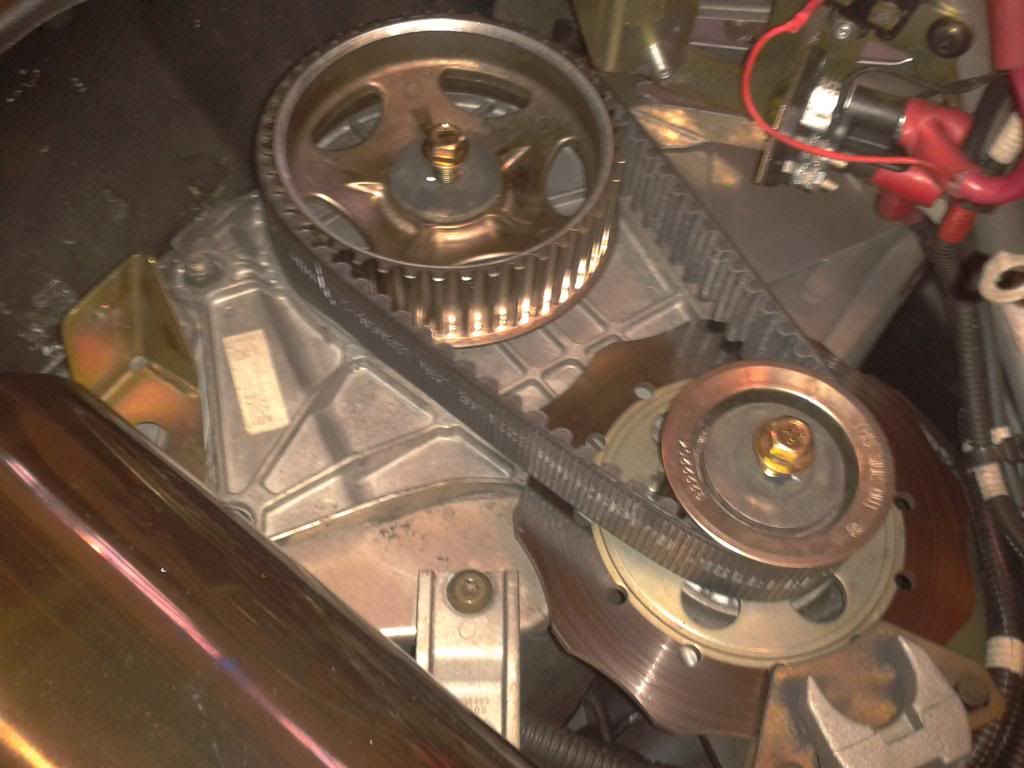

I just lost my second lower QD pulley bolt, and am trying to wrap my head around why / how it fails. I would love to hear some educated insight on this, if anyone has a thought.

The first time, I found the washer floating around in the belly by my clutch, looking around I found the bolt broken off inside the driveshaft. I chalked it up to being over torqued and repaired it myself.

I just lost another bolt, this time the pulley slid out a bit and scraped the battery box, I "modified" the battery box for more room and limped it off the mountain.

-Both bolts broke at about the same spot (just inside the threads on the driveshaft).

-The bolt I installed was torqued to 29ft/lb ( a spec given to me by a sw user), with blue loctite

-I am still running my original driveshaft (clamped) with no problems at 1200 miles.

This time I will seek out a grade8 bolt to install, and I am thinking about lowering my torque. Anyone have any thoughts on the torque, or what forces could be causing this?

From what I can tell (haven't actually removed the pulley) The pulley must sit against a shoulder on the driveshaft. The outer pulley face sits out further than the tip of the shaft fully seated, so the flat washer installed with the bolt only makes contact with the pulley.

Here's my 3 theories:

1- Isolated incidents, the original bolt was overtourqed and snapped. My replacement bolt was inferior, flawed, and/or 29ft/lb is still overtorquing it.

To be honest I have no Idea what grade or brand the bolt I installed was.

2- Are we looking at the possibility that the splines have too much play and the pulley can actually "rock" on the shaft?

This could stress the bolt for sure, but I would expect to see additional problems witch I have not. My pulley feels very secure on the splines, although I have not removed the belt to check more thoroughly.

3- Are the pulleys tapered, or out of alignment causing a constant outward force on the lower pulley? Or Are the jackshaft and driveshaft not precisely parallel to each other?

I did notice that with no bolt holding the lower pulley secure, it had a tendency to ride about a 1/4" out on the shaft supporting this theory (and why I had to bend the rear strap tab on my battery box where the pulley had been rubbing). The sides of the belt were in contact with the shoulders on both QD pulleys so it seemed that this was what was actually keeping the pulley from walking right off the shaft.

The first time, I found the washer floating around in the belly by my clutch, looking around I found the bolt broken off inside the driveshaft. I chalked it up to being over torqued and repaired it myself.

I just lost another bolt, this time the pulley slid out a bit and scraped the battery box, I "modified" the battery box for more room and limped it off the mountain.

-Both bolts broke at about the same spot (just inside the threads on the driveshaft).

-The bolt I installed was torqued to 29ft/lb ( a spec given to me by a sw user), with blue loctite

-I am still running my original driveshaft (clamped) with no problems at 1200 miles.

This time I will seek out a grade8 bolt to install, and I am thinking about lowering my torque. Anyone have any thoughts on the torque, or what forces could be causing this?

From what I can tell (haven't actually removed the pulley) The pulley must sit against a shoulder on the driveshaft. The outer pulley face sits out further than the tip of the shaft fully seated, so the flat washer installed with the bolt only makes contact with the pulley.

Here's my 3 theories:

1- Isolated incidents, the original bolt was overtourqed and snapped. My replacement bolt was inferior, flawed, and/or 29ft/lb is still overtorquing it.

To be honest I have no Idea what grade or brand the bolt I installed was.

2- Are we looking at the possibility that the splines have too much play and the pulley can actually "rock" on the shaft?

This could stress the bolt for sure, but I would expect to see additional problems witch I have not. My pulley feels very secure on the splines, although I have not removed the belt to check more thoroughly.

3- Are the pulleys tapered, or out of alignment causing a constant outward force on the lower pulley? Or Are the jackshaft and driveshaft not precisely parallel to each other?

I did notice that with no bolt holding the lower pulley secure, it had a tendency to ride about a 1/4" out on the shaft supporting this theory (and why I had to bend the rear strap tab on my battery box where the pulley had been rubbing). The sides of the belt were in contact with the shoulders on both QD pulleys so it seemed that this was what was actually keeping the pulley from walking right off the shaft.