2011 163 with silbers new kit. 300kms stock and 500 kms boosted. i got sick of going threw belts and tps sensors and lower and lower compression each ride. so i pulled the turbo kit off and this is what i found. the orange o-rings in the new airbox that seal onto the throttle bodies were both warn out causing a boost leak (explains why i couldnt get over 10 pounds of boost). also i found a thick layer of engine and belt grime in my intake tube and boost tube and alot of black looking gunk entering my turbo. a pre filter is a must in my opinion. also a bunch of my lines were rubbing in tight sopts causing the lines to ALMOST wear threw. i installed the kit myself so probably my fault but there are not a lot of options with such a tight fit. the boost control lines that come pre installed were almost warn threw as well. i also never could get the oil cap to stop leaking. i also had a crack in the aluminum where the only oil tank bolt mounts to the bulk head. i really suggest having a detailed look at all your lines before they rub threw. i only put on 500 kms on this kit and was very supprised on how much rubbing there was. i hope this helps. not bashing justins kit, just trying to make it better. TTT

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SILBER KIT REMOVED/ PROBLEMS FOUND.

- Thread starter tylbz

- Start date

ya its tight in there and next to impossible to keep all the lines from rubbing..IMO all lines should get a 2 minute checkover after every ride, and if you see there rubbing well that aint gonna work.

Buy that plastic ribbed hose protecter from the auto parts store and cover lines that are rubbing, double it up if you want. Those oring tear easily.. and most likely done on install.. there a simple fix. The oil tank moving around to much would caue that crack, thats why silbers updated instructions had us zip tie the tank tighter.

to bad you didnt have any luck with it, going through 2 tps is a stock sled issue IMO.. the TPS are garbage.. mine goes out every couple rides... belt eating would be motor mount or clutching issue.. i had 750 miles on my first belt and it only broke cuz my primary spring broke causing major slippage.

Buy that plastic ribbed hose protecter from the auto parts store and cover lines that are rubbing, double it up if you want. Those oring tear easily.. and most likely done on install.. there a simple fix. The oil tank moving around to much would caue that crack, thats why silbers updated instructions had us zip tie the tank tighter.

to bad you didnt have any luck with it, going through 2 tps is a stock sled issue IMO.. the TPS are garbage.. mine goes out every couple rides... belt eating would be motor mount or clutching issue.. i had 750 miles on my first belt and it only broke cuz my primary spring broke causing major slippage.

Last edited:

O'rings, replace with aircraft quality, I got mine from graingers,super tight fit,I hand beveled the edges of the throttles and air box to make them go in,also be sure to use LOTS of oring grease..

The slp torque arm is a MUST DO to keep motor in line, I also renforced my motor mounts

I use the slp screen as well as the stock vents for intake, again tho after you squeeze the intake hose into the hood, use some top quality duct tape and seal the tube to the hood so there is NO opening to under hood air, your just asking to suck stuff in.

The slp torque arm is a MUST DO to keep motor in line, I also renforced my motor mounts

I use the slp screen as well as the stock vents for intake, again tho after you squeeze the intake hose into the hood, use some top quality duct tape and seal the tube to the hood so there is NO opening to under hood air, your just asking to suck stuff in.

Last edited:

J

Jeff K

Well-known member

Install is crucial to making any turbo kit work well. I installed my kit myself (my 2nd Turbo Sled) and ensured that every line that could possibly rub on something was loomed and secured properly. I also disassembled most of my kit after a couple hundred KM's to fix a bad connection at the one of my secondary injectors and found no other problems with my kit whatsoever. Intake, airbox, throttle bodies were clean. The o-rings on the airbox were worn a bit, but I reused them and I am still getting 12psi. I also have never blown a belt, but I have an SLP torque arm holding the motor from twisting.

O'rings, replace with aircraft quality, I got mine from graingers,super tight fit,I hand beveled the edges of the throttles and air box to make them go in,also be sure to use LOTS of oring grease..

The slp torque arm is a MUST DO to keep motor in line, I also renforced my motor mounts

I use the slp screen as well as the stock vents for intake, again tho after you squeeze the intake hose into the hood, use some top quality duct tape and seal the tube to the hood so there is NO opening to under hood air, your just asking to suck stuff in.

When you say aircraft quality are you referring to viton? I understood there were only three choices of o rings silicon, beuna, and viton.

And do you by chance know the dimensions of the o-rings?When you say aircraft quality are you referring to viton? I understood there were only three choices of o rings silicon, beuna, and viton.

T

TurboMatt

Well-known member

size 330. (2 1/8" ID x 2 1/2" OD)

The silicone ones are the one that Silber uses: http://www.mcmaster.com/#catalog/118/3486/=grneap

The silicone ones are the one that Silber uses: http://www.mcmaster.com/#catalog/118/3486/=grneap

tank

Fyi check your oil tank bolt bracket. If the tank has a little wobble the bracket is probably about to break in the middle of the slot. I luckily was checking things out and not further away from the truck. Had a little oil left to creep back but it fell off again and I had none.

Fyi check your oil tank bolt bracket. If the tank has a little wobble the bracket is probably about to break in the middle of the slot. I luckily was checking things out and not further away from the truck. Had a little oil left to creep back but it fell off again and I had none.

S

Shawn Baker

New member

I built a 3 inch long by 2 inch high double sided bracket to hold the oil tank secure to the bulk head. I also drilled a small hole in the bottum left corner and attached a spring to hold the talk down against the bulk head.

I built a 3 inch long by 2 inch high double sided bracket to hold the oil tank secure to the bulk head. I also drilled a small hole in the bottum left corner and attached a spring to hold the talk down against the bulk head.

You have a pic you could post?

pics

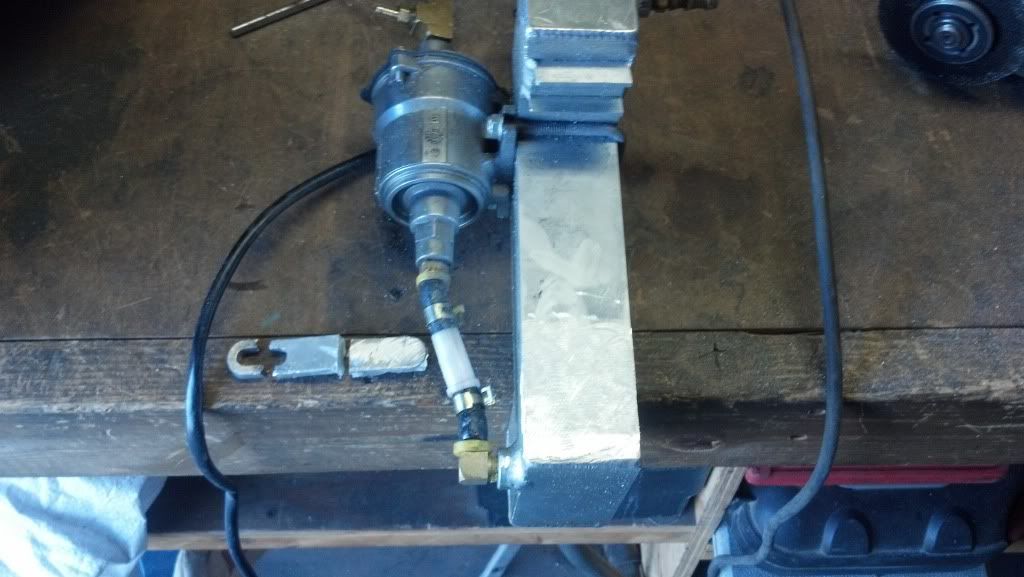

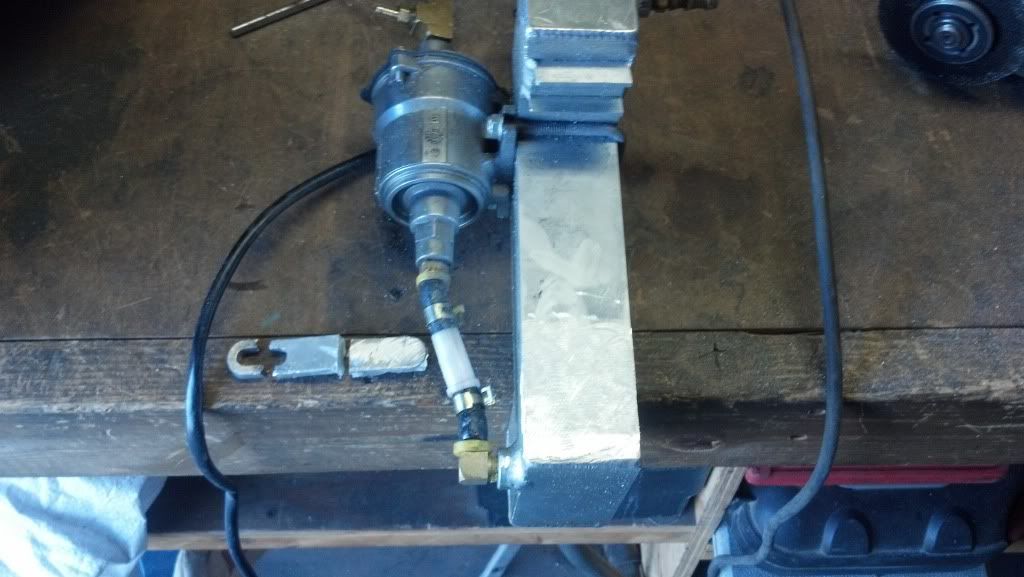

heres my fix and as many of you know, I HATE ALUMINUM STICK WELDING!!!

but it had to be done

heres my fix and as many of you know, I HATE ALUMINUM STICK WELDING!!!

but it had to be done

pssst Josh...theres a birdy in your shop crapping on your welds...

pssst Josh...theres a birdy in your shop crapping on your welds...

we had an aluminum spool gun but my buddies exwife sold it in the "auction" or as it really could be described "theft". so im stuck with my little junk buzzbox and the stupid aluminum stick, im sure satan produces it.

we had an aluminum spool gun but my buddies exwife sold it in the "auction" or as it really could be described "theft". so im stuck with my little junk buzzbox and the stupid aluminum stick, im sure satan produces it.

Did you reverse your welding leads?

Shouldn't the hole be where you can put a bolt thru it? Too bad you don't live in Alaska, I'd have built you a decent tank for free, so I didn't have to puke in my mouth just from viewing the photo. Spool guns suck for making decent air tight welds also, GTAW is where it is at. Purdy welds and the ultimate in control.

hey

Quit dissin my quality product haha. With the junk welder I have there is no good parameter to set. I have tried every variation and its just a battle from every direction. I saw a miller xmt 350 in a pawn shop for 2200 a few months back and kick myself every time I have to pull this junk out for not buying it.

Truly sucks even more when I'm used to working with all these quality machines every day and have to use crap at home.

Quit dissin my quality product haha. With the junk welder I have there is no good parameter to set. I have tried every variation and its just a battle from every direction. I saw a miller xmt 350 in a pawn shop for 2200 a few months back and kick myself every time I have to pull this junk out for not buying it.

Truly sucks even more when I'm used to working with all these quality machines every day and have to use crap at home.

Welding aluminum that has had oil in it is always a challenge. It never seems to get clean enough to weld like fresh material.

Here is how we fixed the ones that were sent to us. Great minds think alike!

Here is how we fixed the ones that were sent to us. Great minds think alike!

That one is your tank TJ

Similar threads

D

- Replies

- 8

- Views

- 4K

D

G

- Replies

- 21

- Views

- 4K