Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RMK 900 Motor Mounts 05 vs 06

- Thread starter Mech Engr

- Start date

M

Mech Engr

Well-known member

The are exactly the same except for better rubber so they will bolt right in.

A direct answer to my question...Thanks man!!

M

Mech Engr

Well-known member

mounts

I looked at the mounts with the motor still in the sled and they look great from what I can see. I'll be using this long weekend to remove the motor (likely Mountainhorse will hear the profanity throughout the day in our small town as I remove it!!) for new mounts if needed, SLP torque/push arm set up and 06 pistons.

for new mounts if needed, SLP torque/push arm set up and 06 pistons.

How can I tell if the mounts are OK? The front mounts are pretty expensive and I don't want to buy them if I don't have to.

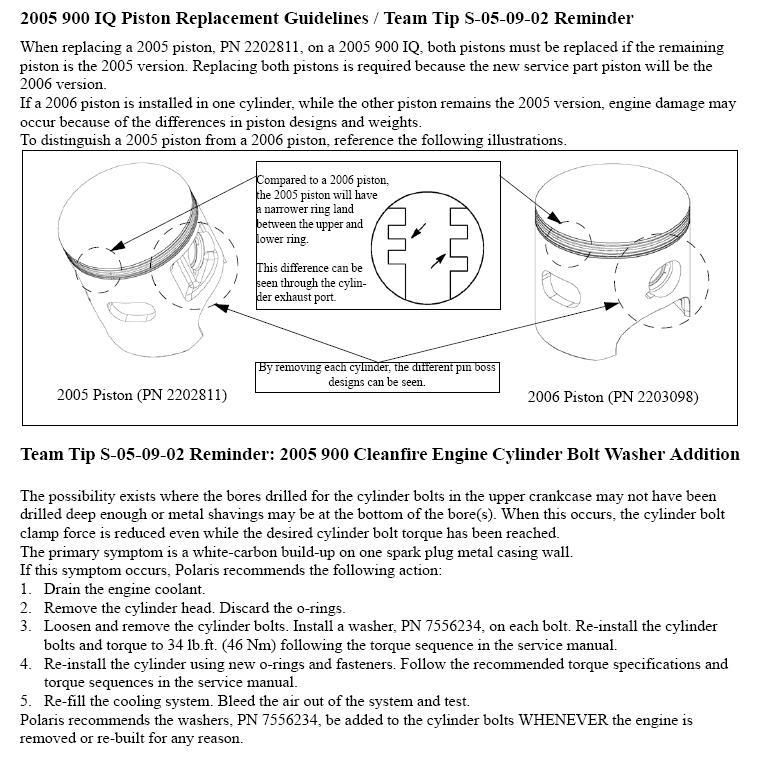

Also, a question I asked in another post that went unanswered: how can I tell if the pistons I have are the 06 already when I tear the top-end down? I'd rather just re-ring and do a super light hone if it already the 06 pistons.

Thanks, John

I looked at the mounts with the motor still in the sled and they look great from what I can see. I'll be using this long weekend to remove the motor (likely Mountainhorse will hear the profanity throughout the day in our small town as I remove it!!)

How can I tell if the mounts are OK? The front mounts are pretty expensive and I don't want to buy them if I don't have to.

Also, a question I asked in another post that went unanswered: how can I tell if the pistons I have are the 06 already when I tear the top-end down? I'd rather just re-ring and do a super light hone if it already the 06 pistons.

Thanks, John

If you have it out...Replace them, Period.

I'd bet yours are bad

Drop me a PM with your phone number.

I'd bet yours are bad

Drop me a PM with your phone number.

IMO.. Dont Do a hone unless you have a set of diamond hones and know how to use them.

M

Mech Engr

Well-known member

mounts

PM sent.

If you have it out...Replace them, Period.

I'd bet yours are bad

Drop me a PM with your phone number.

PM sent.

If you have it out...Replace them, Period.

I'd bet yours are bad

Yup, think about how much work it is to pull the motor and ask yourself it you want to do it twice because you didn't replace them. The fronts will be the ones to fail because of the angle that the engine pulls against them under load.

From Parts pitstop

3021753 Polaris - MOUNT-ENGINE, FRONT 60 $38.35 2 $76.70

Contact freeagent on here and she may be able to get you a better price on everything you need.

http://www.snowestonline.com/forum/member.php?u=62212

Last edited:

Why was my post deleted?

Dave... I see no post deleted... Are you sure it posted??

OR

Like I've done before... post in another thread you had open (the PRO RMK mount thread)???

OR

Like I've done before... post in another thread you had open (the PRO RMK mount thread)???

If a mod deleted it ... you would have received a PM telling you it was deleted.

If you have a 900 or 2006 700 (755) IQ... there is a good chance your motor mounts are broken (Torn).

There are a lot of reasons this happens....from the overall torque of the motor, to the position of the secondary clutch on the 2005's to super steep helixes, to poor construction to people

prying up on the motor to get access to parts.

Most of the 2005's that I've had apart have torn motor mounts... many of the 2006 I've done have the same thing.

Belt life, crankshaft failure poor performance and inconsistent running are all symptoms of these mounts going bad.... but some might not really notice with these new 3211115 belts on the sled...

but the performance will be down and this exposes your crankshaft taper to abuse and possible failure.

The fronts more than the rears... BUT if your fronts are ruined, the rears were probably damaged as they try to hold the motor in place by themselves.

The bummer is you cant tell if they are torn until you pull the motor.

It is good preventative maintenance to replace these as they are inexpensive from www.hiperf.com.. they only list the 2006's but they fit the 2005's as well.

#345-512 fronts, #345-513 rears

Listed for 2006 only, but they also fit the 2005's

Get your fuel filters for the 900/755'shere too.... cheaper than the dealer.

If you remove your stock mounts, to see the damage, put it in a vise as shown.

This pic shows a 2005 900 front motor mount. The mount was "laid over" in a vise to show the torn rubber.

This mount looked normal at first inspection!!

IMO, best to pull the complete engine and give yourself the ability to clean and check everything out.

I also strongly suggest replacing all the bolts in the mounts with Grade 8 or better (L-9 or ARP high strength bolts)

(4ea of #18, 2ea #9, 2ea, #16 fro the diagram below.

Now, if you want to go with the ultimate front mount that is basically a bolt in (you will only need to drill 4 holes)... go with Compfusion's mounts (compfusion is a members name on this forum)

super high quality stainless steel, urethane and aluminum components.

...

The 05... just use the 06 mounts... replace the rear mounts..

Use Grade 8 bolts

AND

Look for the thread on aligning the motor from SW...

Although I disagree that you can actually align the motor (the alignment is set by the front mounts and will return to neutral IMO)... It makes a brilliant point... That the distance between the two rear mounts and distance between the outer surface of the rear-mount mounting ears is different... the motor is more narrow by a fair amount in many of these sleds (2005 900's and 2006 900/700's)

You can shim the rear mounts so that they match the same width as the distance between the mounting "ears" at the rear so that they sit in a neutral position and are not strained from the start.... pretty fast and easy...

Many of the sleds suck down the rear PTO mount and place an in line load (in line with the bolt) on the mount which it was never designed to do...The rear mounts FAIL when an in line load is placed on them.

This problem was prevalent enough that Polaris actually put a thrust washer and urethane puck on the PTO side to help suck down the bulkhead wings without placing undue stress on the LH Rear motor mount, even though it does flex the heck out of the Mag side mount and pulls the general alignment out...

I've seen some sleds go in for this mount update that became "belt eaters" after this was done. (Alignment was pulled out as pointed out by SW)

If you loosen the rear LH mount bolt with the displacement washers in place... you will actually see the bulkhead flex open at that point... when thighened this also stresses the mount casting (#5) in the bulkhead and causes deflection of the PTO side jackshaft bearing location when this is "sucked-down" to the mount. This jackshaft deflection is more evident on the 2005's than the 2006's which mounts the jackshaft (and the bearing-mount-casting) closer to the roll of the bulkhead.

You will notice on those urethane deflection washers a round groove worn in them from constant contact, under extreme pressure against the casing of the LH rear mount (#15)

As long as you do not put any side load on the rear motor mounts...which is what the shimming does.. you should not have any problems as long as your bulkhead is not bent from a wreck.

This being said... most of the 2005's that I've taken apart have torn front motor mounts in them... which you cant tell easily even with the motor out... you have to put them in a vise and lay them over a bit... In ANY case... I recommend that stock-2006 or Compfusion mounts are updated in all 2005 sleds.

You will notice in the dwgs below that the 05 (original) design only had bolt #9 for the LH rear mount to the chassis... This was updated with TSB S-05-06 with the Thrust washer (Called "torque stop limiter and washer") installed in all 2006 sleds. (#1, 2, 14 in 2006 dwg)

I have had a couple of 2005's that I've worked on, that when the distance between the mounts is shimmed correctly... the limiter/deflection washer was removed altogether and the sled vibrated less.

Another problem with the design is that the factory torque-stop (#12)remained in the same position on the 2006's even though the jackshaft was dropped by quite bit. The Torque stop should be placed INLINE with the primary/secondary line.

2005 LH mount Drawing

2006 Mounting Drawing

...

WPS has them... part number 11-4016 for the front... $49, rear 11-4017 $39

ebay $39 each for the front

http://cgi.ebay.com/ebaymotors/290512664822

ebay $39 each for the front

http://cgi.ebay.com/ebaymotors/290512664822

If a mod deleted it ... you would have received a PM telling you it was deleted.

Well then it disappeared. I remember reading it after it posted and after that as the last post in the Polaris section seeing the thread title and my name in the main menu.

Oh well...It's not a big deal. I figured it might have ruffled someones feathers as the general theme of my post was endorsing the 06 OEM mounts with the recommendation of replacing them every 2 seasons.

the pin boss is the dead giveaway.