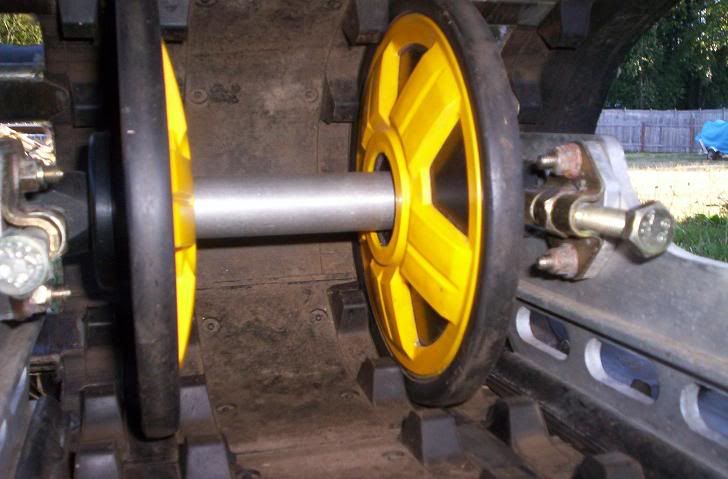

I did this. I cut the axle to 9" long. Then drill and tap the cut end to fit your axle bolt. You then have to cut the aluminum sleeve the correct length to fit between your wheels once located to the inside. I forget the measurement. The stock outer sleeves are the correct length. I also located the adusting screws to the inside of the rails. I used a piece of 1.5" x 1.5" aluminum flat stock to make larger washers for the outside of the rails to put the axle bolt through. The only issue that I had was the axle needs to be machined so that the bearings will fit. It is slightly larger in diameter where the wheels have not been and the bearings wouldn't slide to their new location. Hope that helps. Good luck.