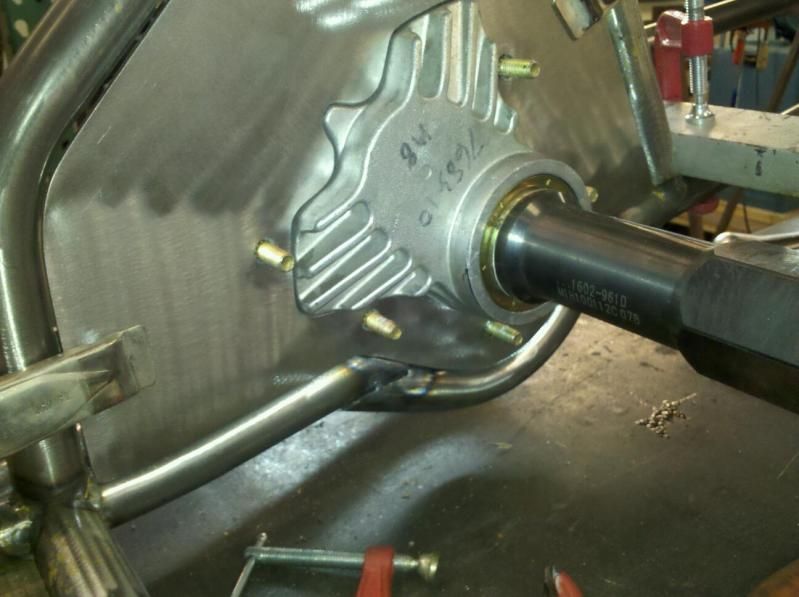

We are running 1in .065 tubing. Its built stout, but my brother 260lbs, is pushing over 400hp and jumps the the 150ft so it needs to be strong!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I love the tube chassis especialy since I am a tube bender guy myself. I got a tube frame dune buggy in the work using a sled engine but I never thought of building a tube frame sled......hmmmm.....

I love the tube chassis especialy since I am a tube bender guy myself. I got a tube frame dune buggy in the work using a sled engine but I never thought of building a tube frame sled......hmmmm.....Man that thing is awsome.I love the tube chassis especialy since I am a tube bender guy myself. I got a tube frame dune buggy in the work using a sled engine but I never thought of building a tube frame sled......hmmmm.....

Awsome skills. Hardest part is the jig. What tube bending program and bender are you using? I will be keeping an eye on this build. Makes my little old indy 400 build look like peanuts

What is the degree of rake on the front end of that. Does the camber change as the suspenssion cycles. I would think with a sled you would want the spindle to remain as verticle as possible through the suspension cycle.Looks like it will roll over the bumps nice. I could never figure out why they don't make more sled with a bit of rake.

I like that your hammer matches your A arms, nice attention to detail

You should look into "bend tech" software. I have the pro version for tube work and the sheet metal version (SM) for designing plate for laser cutting. The price is very reasonable, around $300 if I remember correctly, and the customer service is the best around. With bend tech pro and SM you can desing any tube chassis and any plate work that goes with it. It can even design plate work for cnc bending.

What are the last 2 pictures of, Suspension mounts?

Any updates ?