Let me first say Im not a great rider. Maybe for some paneling out with an extra inch of width actually makes a difference for them that they notice? I know on a bike where you contact the road an inch is a big deal but on snow??? I was first cursing the clearance pulling the belt off now Im really annoyed. I would normally blame the aftermarket part and bitch at them but not like there was much clearance with the stock cover compared to the Fire and Ice and pretty sure there would still be contact. Trying to decide if I should remove the factory wear bar thing or not. Not thrilled with the idea of it grinding further and getting ripped of and bouncing around into my clutch or belt. Or maybe it has self clearanced its self enough to just wear on the center button like its supposed to? Also secondary bolt is eating into the panel. So 1/2 a rant and also a question on what you guys are doing about the contact.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Narrow body panels suck

- Thread starter ratlover

- Start date

V

volcano buster

Well-known member

Probably best to just stay on the trail.

Probably best to just stay in the trailer.

R&D overlooks details at times. Anyone remember the IQ chassis that for some reason you had to change out exhaust valve springs after a year or two because they were so crappy and rusted?

The one most affected was the mag side, it was because the drain for the intake plenum was perfectly aligned with the hole on the exhaust valve cap ,Perfectly.

The one most affected was the mag side, it was because the drain for the intake plenum was perfectly aligned with the hole on the exhaust valve cap ,Perfectly.

Probably best to just stay on the trail.

Sadly most of the last trip was spent on the trail or in the trailer. But at least not the Cat’s fault.

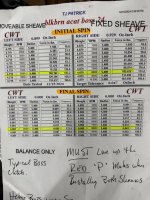

I sent my both clutches to Patrick custom carbon. Shout out to him for his quick turn around and taking all the time to go over things with me. I wanted just balanced since I was adding the cover and think I ended up with it lightened with as many holes as he had to drill  Found his comments pretty amusing. Figured while he had the primary was worth the extra $ to have the secondary balanced and was glad I did.

Found his comments pretty amusing. Figured while he had the primary was worth the extra $ to have the secondary balanced and was glad I did.

Attachments

Nope. I didn’t want to put the cover on without balancing and didn’t want to be down during the season waiting on shipping back and forth. In hindsight with the quick turn around I probably coulda rode it stock for a ride or 2 and not missed any planned trips and wish I would have. When talking to him about weather it was worth it to balance the secondary he recommended it since from factory they aren’t the greatest and they dont get balanced as a unit so depending how you install the inner and out sheave you could make it better or worse. He puts marks on the secondary to get em installed the same every time.

B

I wondered about the weight increase with the cast steel spider that Cat changed to. I guess that confirms it.I sent my both clutches to Patrick custom carbon. Shout out to him for his quick turn around and taking all the time to go over things with me. I wanted just balanced since I was adding the cover and think I ended up with it lightened with as many holes as he had to drillFound his comments pretty amusing. Figured while he had the primary was worth the extra $ to have the secondary balanced and was glad I did.

I believe a member on here weighed a P85 and an Adapt.. I wanna say the P85 was around 9lbs and the Adapt was 14lbsI wondered about the weight increase with the cast steel spider that Cat changed to. I guess that confirms it.

Secondary clutch bolt chews into the panel. Has nothing to do with the fact I balanced the clutch. And don’t see how I wouldn't be contacting even with the stock cover on the primary laying the sled over on its side. I have no problem placing blame on my choice to modify from the factory but I don’t see how there wouldn’t be an issue either way.So you put on a aftermarket part but this is Cats fault?

F

frozenfarmer

Active member

Well, I wouldn't be expecting much sympathy if a tower cracks on your clutch. That is not an area to have a drill point for balancing on the towers like that.

Highly guessing that is aftermarket balancing. thought I had seen where the factory balanced using the steel spider for balance holes. The aluminum casting is the least effective spot to balance.

Highly guessing that is aftermarket balancing. thought I had seen where the factory balanced using the steel spider for balance holes. The aluminum casting is the least effective spot to balance.

Wow. Just noticed that on this thread. What aftermarket company drilled into his towers like that? No buenoWell, I wouldn't be expecting much sympathy if a tower cracks on your clutch. That is not an area to have a drill point for balancing on the towers like that.

Yes it is Cats fault, the dumbies forgot to account for the new position of the 858 motor. Lots of pictures of that huck rivet eating stock primary covers too. But hey, keep your head in the sand and pretending everything is perfect on this sled!!So you put on a aftermarket part but this is Cats fault?

Sucks Ratlover was not aware of that issue. But that is why we have these posts, to get the word out and give everyone a heads up.

Has anyone had their dealer address this issue? Would be great to know AC's solution for this. I came up with my own solution in the interm as my dealer is 2 hours away. Warranty or not, I see no reason to let that huck rivet eat the primary cover but maybe others don't care.

I don't think anything is appreciably weakened but it's hard to believe a clutch needed that much drilling. What did it look like before?Wow. Just noticed that on this thread. What aftermarket company drilled into his towers like that? No bueno

F

frozenfarmer

Active member

The tower transfers engine torque so it is going to "bend" or stress the area where the green arrow is on the casting to varying degrees. The two holes placed in the base of the tower are pretty concerning. The other question that isn't answered without cross-sectioning the part is how close are those drill points to the dowel pin and bolt hole. You want to stay away from those areas as minimal thickness causes cracks generally.I don't think anything is appreciably weakened but it's hard to believe a clutch needed that much drilling. What did it look like before?

I hope they are willing to buy a primary for their customer if it fails through a drill hole from their balancing.

My comment had nothing to do with the placement of the plastic device, remove the device and that thicker cover will still rub more than the stock coverYes it is Cats fault, the dumbies forgot to account for the new position of the 858 motor. Lots of pictures of that huck rivet eating stock primary covers too. But hey, keep your head in the sand and pretending everything is perfect on this sled!!

Sucks Ratlover was not aware of that issue. But that is why we have these posts, to get the word out and give everyone a heads up.

Has anyone had their dealer address this issue? Would be great to know AC's solution for this. I came up with my own solution in the interm as my dealer is 2 hours away. Warranty or not, I see no reason to let that huck rivet eat the primary cover but maybe others don't care.

Similar threads

- Replies

- 0

- Views

- 2K

- Replies

- 145

- Views

- 26K

F

S

- Replies

- 6

- Views

- 5K

S