I'm almost finished up installing an X3 track on my 2012 RMK Assault and thought I should post up some pics for anyone interested in doing the same to their sled. This sled has a chaincase. For 2013 and newer belt drive RMKs, obviously no chaincase mods necessary.

Out with the old 5.1 and in with the new X3. I picked up the track, drivers and anti-stab from Tracks USA. They had a smokin' deal going on last spring.

Strippin' the sled down:

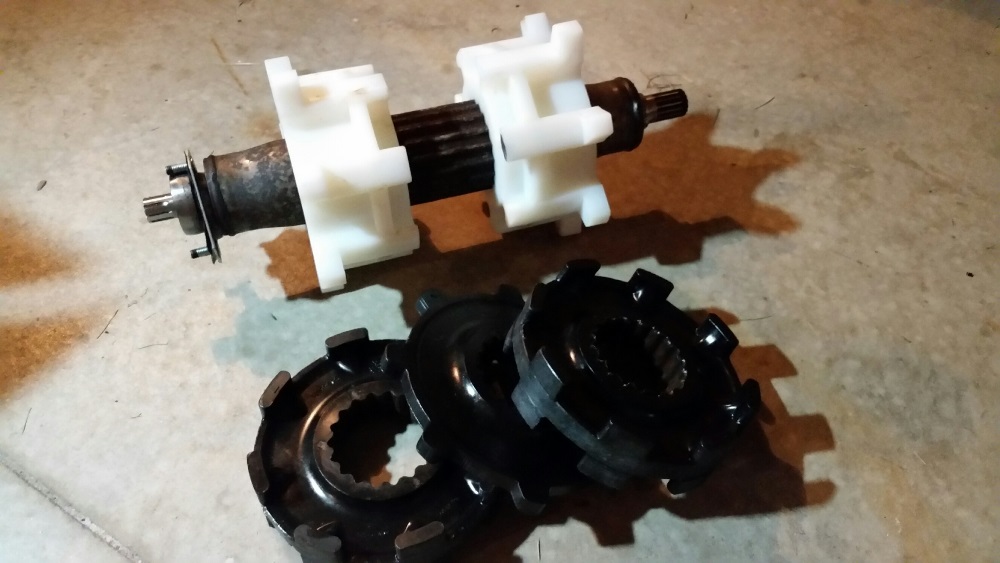

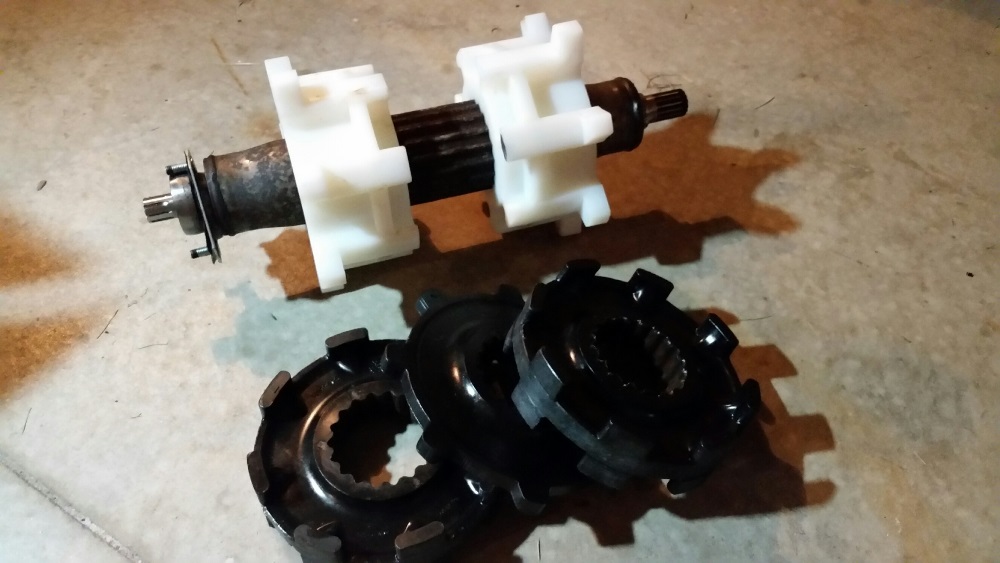

To get the clearance necessary, you can either do a drop and roll or just get 7 tooth Avid drivers(stock is 8). I chose extrovert drivers, since they essentially eliminate ratcheting and won't ice up like the involute(stock style) drivers sometimes do. Avid has a good writeup on their site on how to install these.

The chaincase is glued on 2012 and newer chaincase sleds. There's a good thread going on the Lords adhesive used. Essentially, you heat it up from inside the tunnel until the glue 'pops' free. Definitely glue back on, but don't use a regular epoxy, unless you don't ever want to get it off again. The Lords adhesive is specifically designed to come loose at a certain temperature.

Also, when removing the front torx bolt of the chaincase, heat it well or you run the risk of breaking it.

I had a local shop weld the case for me. Not the most beautiful welding job, but it'll work. I recommend leaving the bearings in the case as it's being welded so that the bearing pockets don't go oblong from the heat. Obviously replace the bearings and seals with new ones afterward.

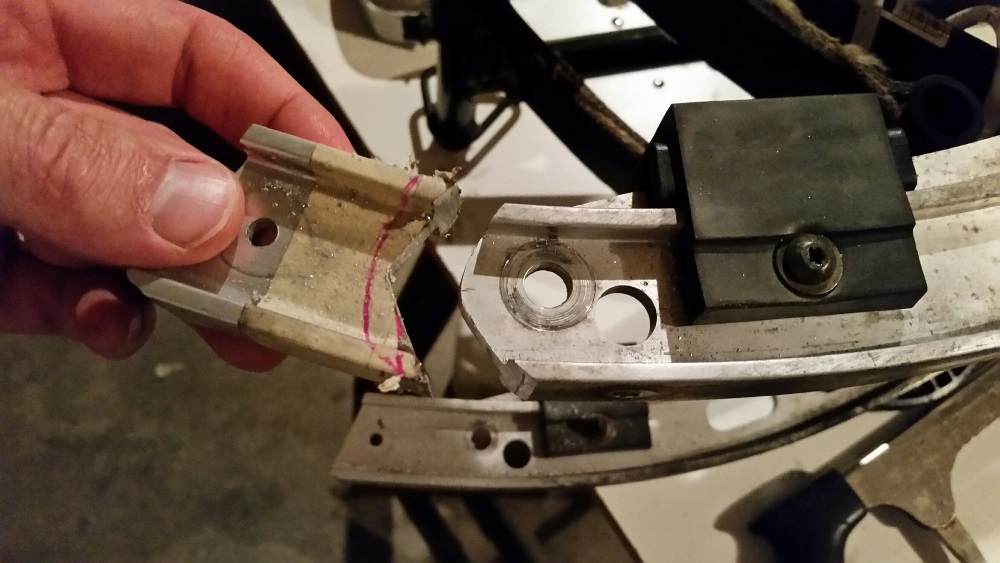

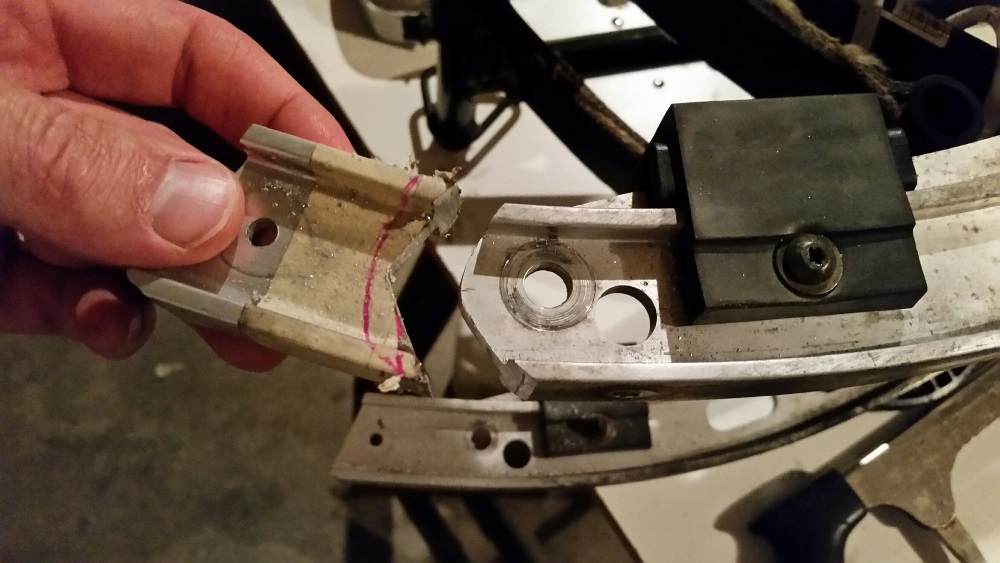

Ya gotta cut out the chunk shown in the pic. It's not an exact science, but basically cut from where the bolt flange ends on the bottom of the case, up to the half way mark of the bump out on top. Grind it flush and replace with a 1/8" plate or less. The new plate doesn't need to be flush with the back of the chaincase. It can bump out the plate thickness.

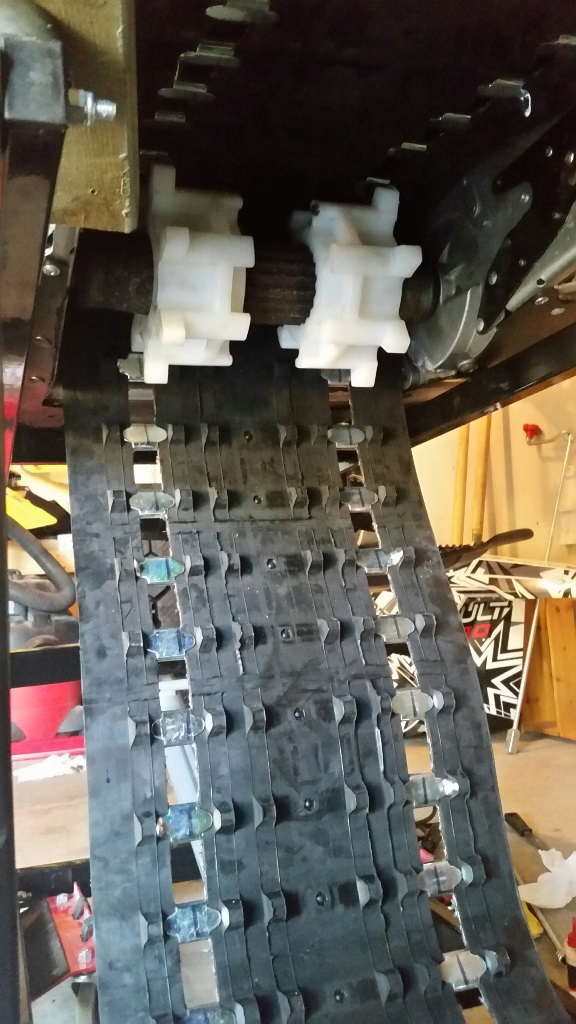

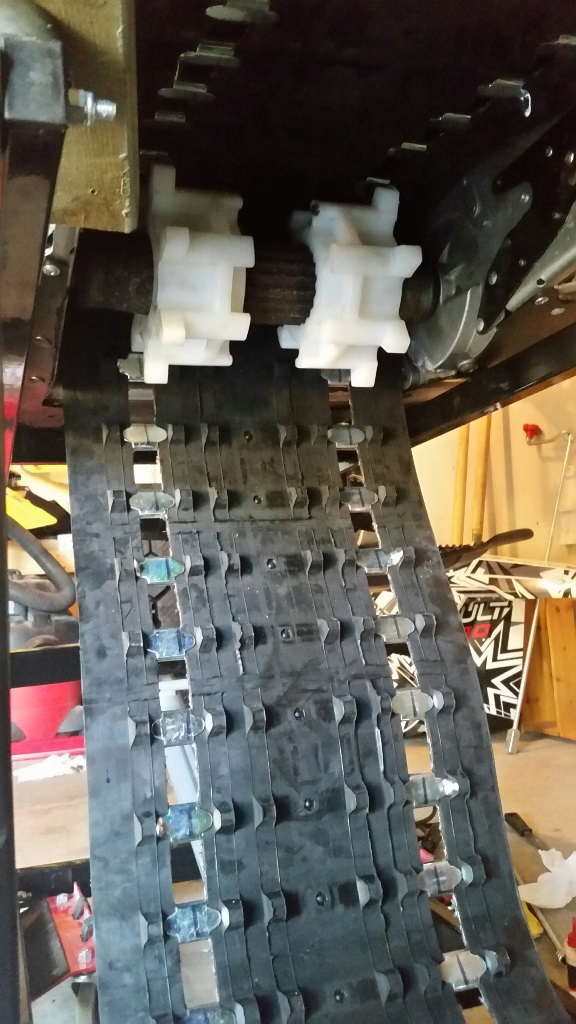

Pic with the chaincase reinstalled and drivers in. I highly recommend you put the drivers in BEFORE you reinstall the chaincase. By doing this, you eliminate the risk of dinging up your new drive shaft seal that you just installed on the back of the chaincase.

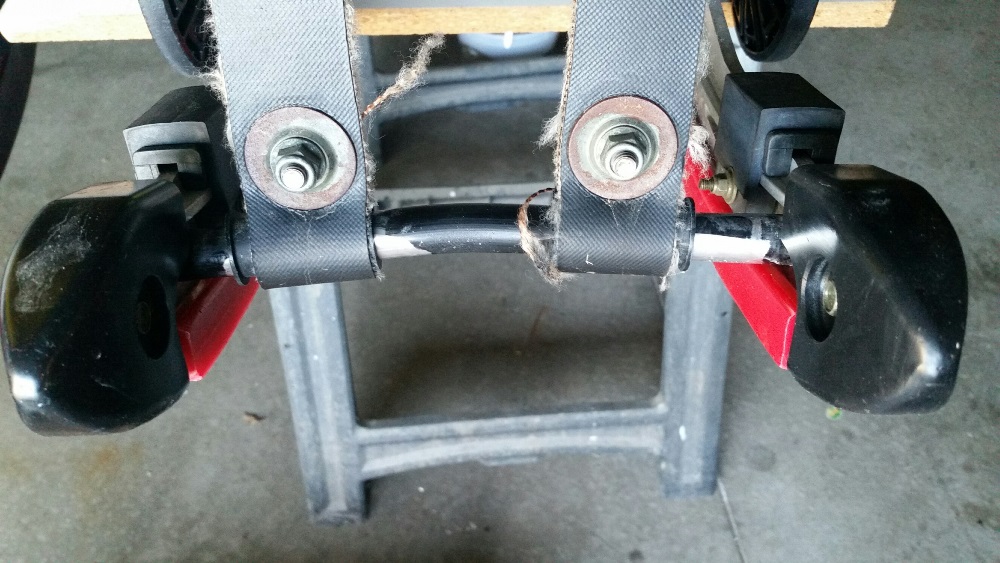

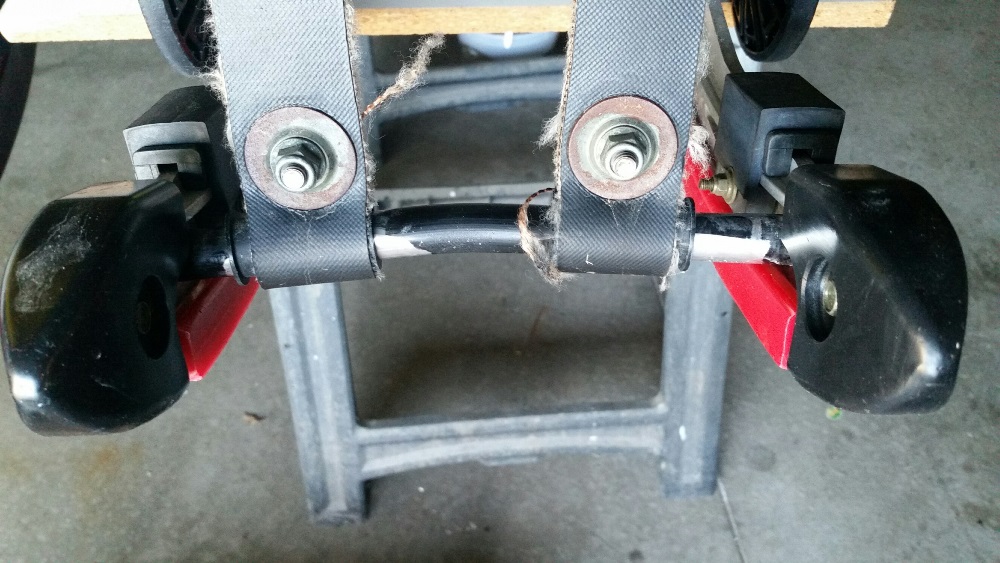

With extrovert drivers, you gotta cut the tips of the rails off for clearance. But when you do this, you must install an anti-stab. Does something look bent to you?

The anti-stab wheels mount where the old limiter strap bar was. I measured 3/4" from the axis of the antistab hole and cut away.

Then install the anti-stab. Trim the hyfax to fit and be sure to put a 45 degree chamfer on the front of the hyfax. I still need to trim one of the hyfax in this pic. If you have only one limiter strap, add another one.

Next up is cleaning and greasing the skid. I also put a 210# spring on the RTS. I wanted a 230# spring, but I got a good deal on the 210#. We'll see how it works.

Clutching is after that. Thinking of doing 62gm Belly Busters with stock spring in the primary, Black/Purple(160-240) spring in the secondary, with teflon washer and 60-42-36 helix. Let me know what you think about that setup.

Out with the old 5.1 and in with the new X3. I picked up the track, drivers and anti-stab from Tracks USA. They had a smokin' deal going on last spring.

Strippin' the sled down:

To get the clearance necessary, you can either do a drop and roll or just get 7 tooth Avid drivers(stock is 8). I chose extrovert drivers, since they essentially eliminate ratcheting and won't ice up like the involute(stock style) drivers sometimes do. Avid has a good writeup on their site on how to install these.

The chaincase is glued on 2012 and newer chaincase sleds. There's a good thread going on the Lords adhesive used. Essentially, you heat it up from inside the tunnel until the glue 'pops' free. Definitely glue back on, but don't use a regular epoxy, unless you don't ever want to get it off again. The Lords adhesive is specifically designed to come loose at a certain temperature.

Also, when removing the front torx bolt of the chaincase, heat it well or you run the risk of breaking it.

I had a local shop weld the case for me. Not the most beautiful welding job, but it'll work. I recommend leaving the bearings in the case as it's being welded so that the bearing pockets don't go oblong from the heat. Obviously replace the bearings and seals with new ones afterward.

Ya gotta cut out the chunk shown in the pic. It's not an exact science, but basically cut from where the bolt flange ends on the bottom of the case, up to the half way mark of the bump out on top. Grind it flush and replace with a 1/8" plate or less. The new plate doesn't need to be flush with the back of the chaincase. It can bump out the plate thickness.

Pic with the chaincase reinstalled and drivers in. I highly recommend you put the drivers in BEFORE you reinstall the chaincase. By doing this, you eliminate the risk of dinging up your new drive shaft seal that you just installed on the back of the chaincase.

With extrovert drivers, you gotta cut the tips of the rails off for clearance. But when you do this, you must install an anti-stab. Does something look bent to you?

The anti-stab wheels mount where the old limiter strap bar was. I measured 3/4" from the axis of the antistab hole and cut away.

Then install the anti-stab. Trim the hyfax to fit and be sure to put a 45 degree chamfer on the front of the hyfax. I still need to trim one of the hyfax in this pic. If you have only one limiter strap, add another one.

Next up is cleaning and greasing the skid. I also put a 210# spring on the RTS. I wanted a 230# spring, but I got a good deal on the 210#. We'll see how it works.

Clutching is after that. Thinking of doing 62gm Belly Busters with stock spring in the primary, Black/Purple(160-240) spring in the secondary, with teflon washer and 60-42-36 helix. Let me know what you think about that setup.