W

White-Powder

Member

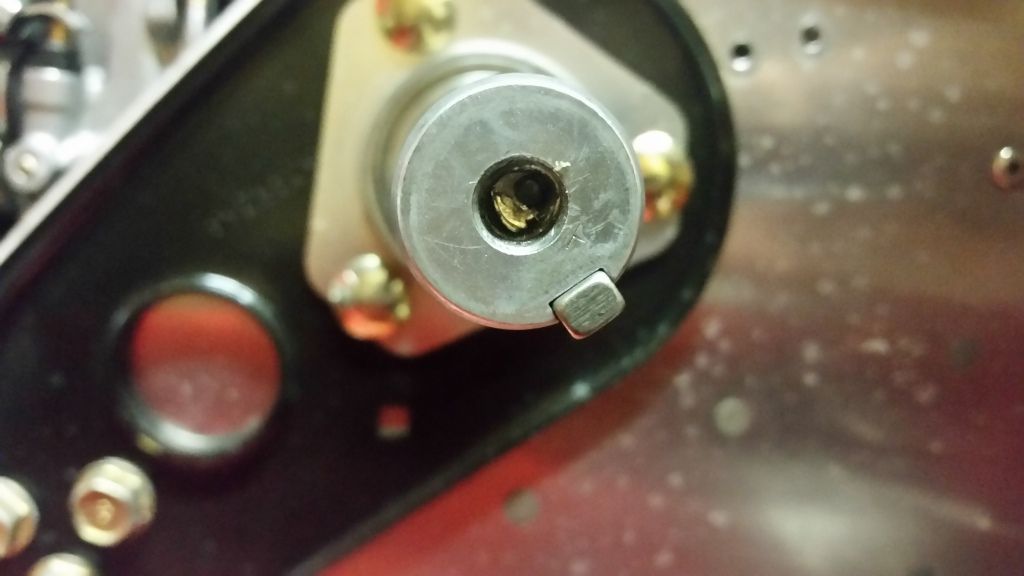

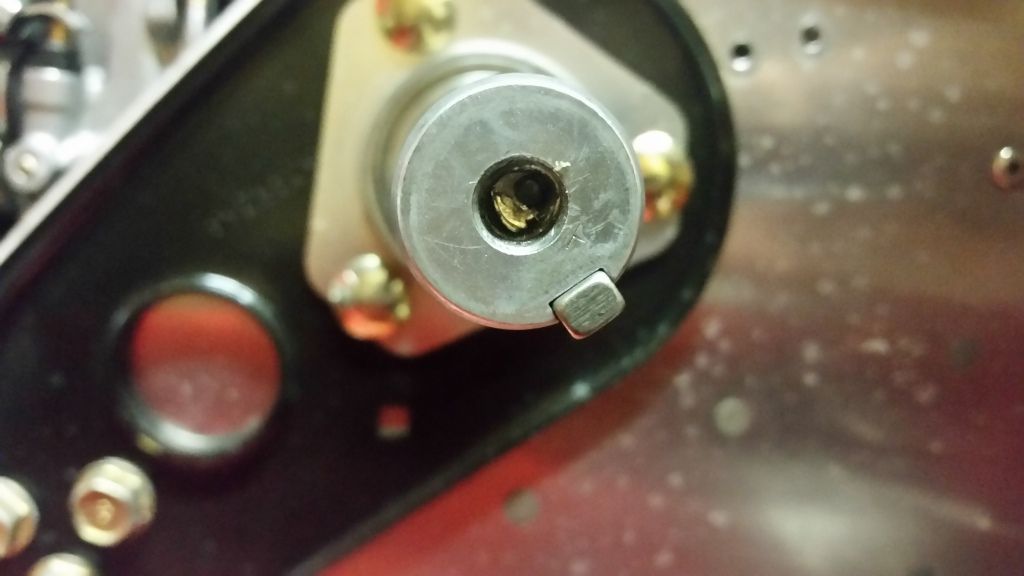

So today I went to put my bolt back on to reinstall secondary and I mistakingly used my impact to tighten and it soon broke off inside the jackshaft. I have tried using my left handed bits etc to no avail...The bolt is broke off about a 1/4" into the hole so can't just grab on to it...When I tried drilling into it the bit moved slightly to the side and I am not sure yet if I messed up any threads on the jackshaft but IF I did, would I be able to rethread the hole or use a helicoil for this repair? New jackshaft costs me $289...This is a 2015 IQR stocker I plan on racing this year...Any help much appreciated!