C

ck3700

New member

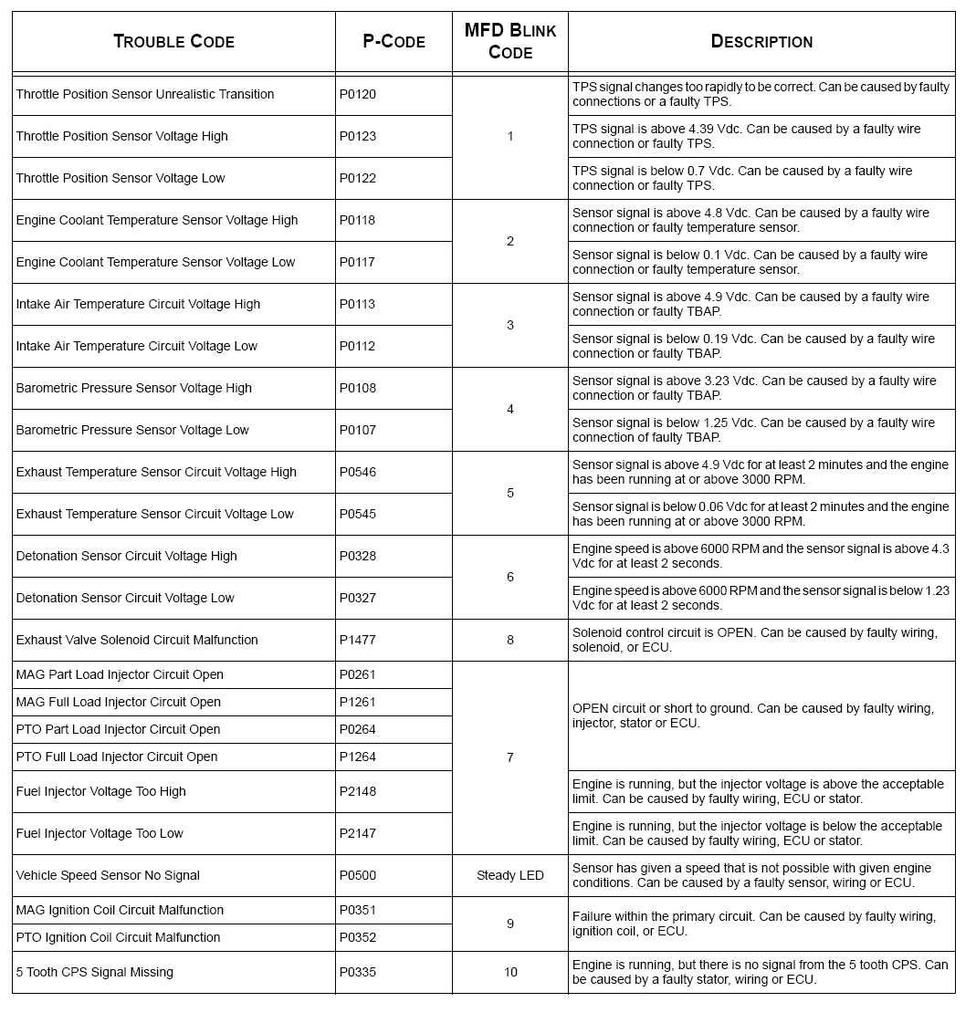

Could somebody tell me what the normal temp range would be for a 2005 900 fusion on the digital display? I have a fresh engine, and was putzing around the yard with it, to start break in, and the display got up into the 170's.. The check engine light was flashing, but not the temp light, so idk.. Are you supposed to count flashes on the check engine light, to figure out codes? Or is that on the service light?? Coolant was full.. Gas is premixed 50:1, plus oil injection. Running boards nice and warm. Thanx for any insight.

.. I have never even seen this light come on before, until now of course.. I will run it again tomorrow, and see if the light flashing returns, and report back.

.. I have never even seen this light come on before, until now of course.. I will run it again tomorrow, and see if the light flashing returns, and report back.