B

bustamove

Active member

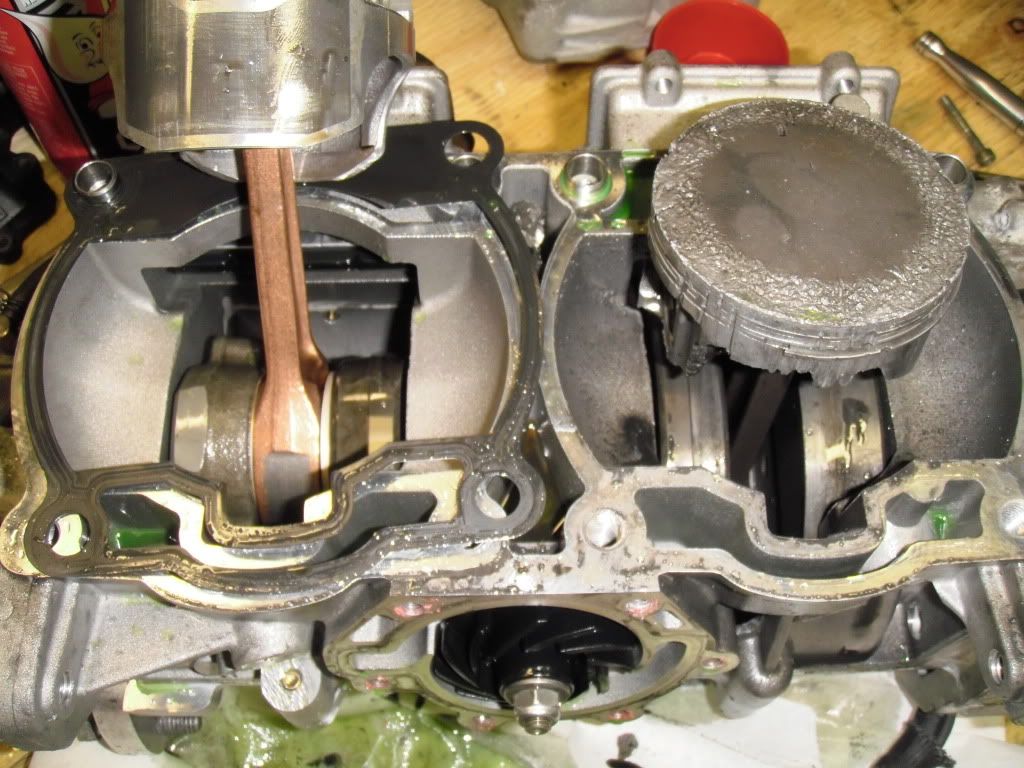

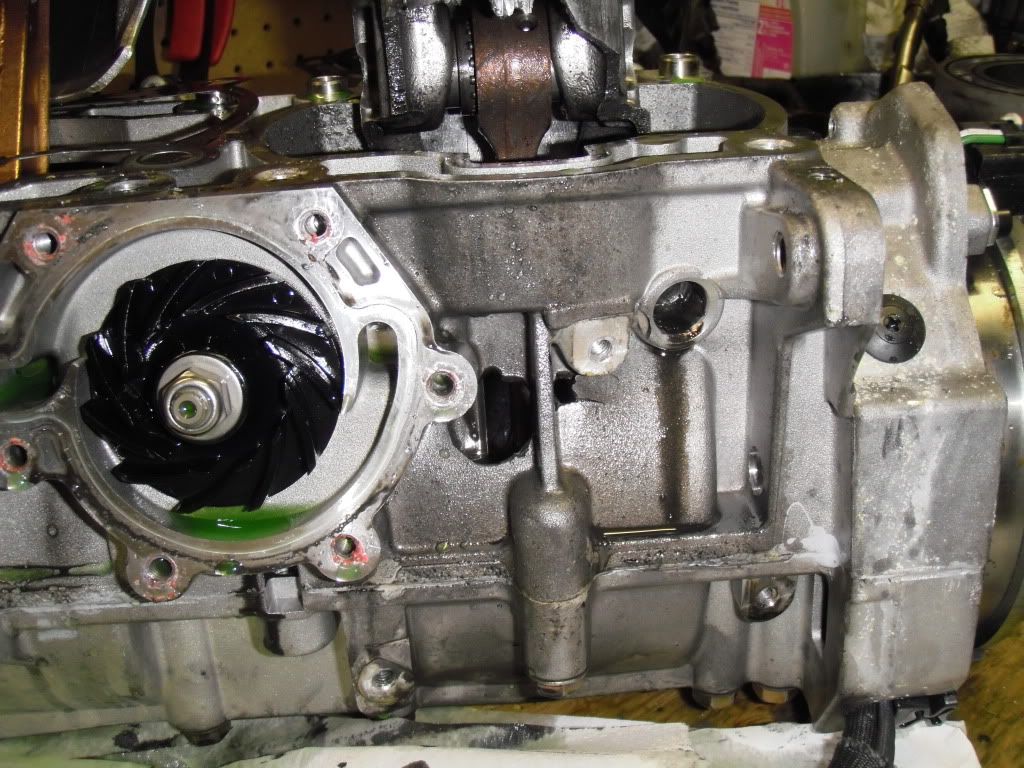

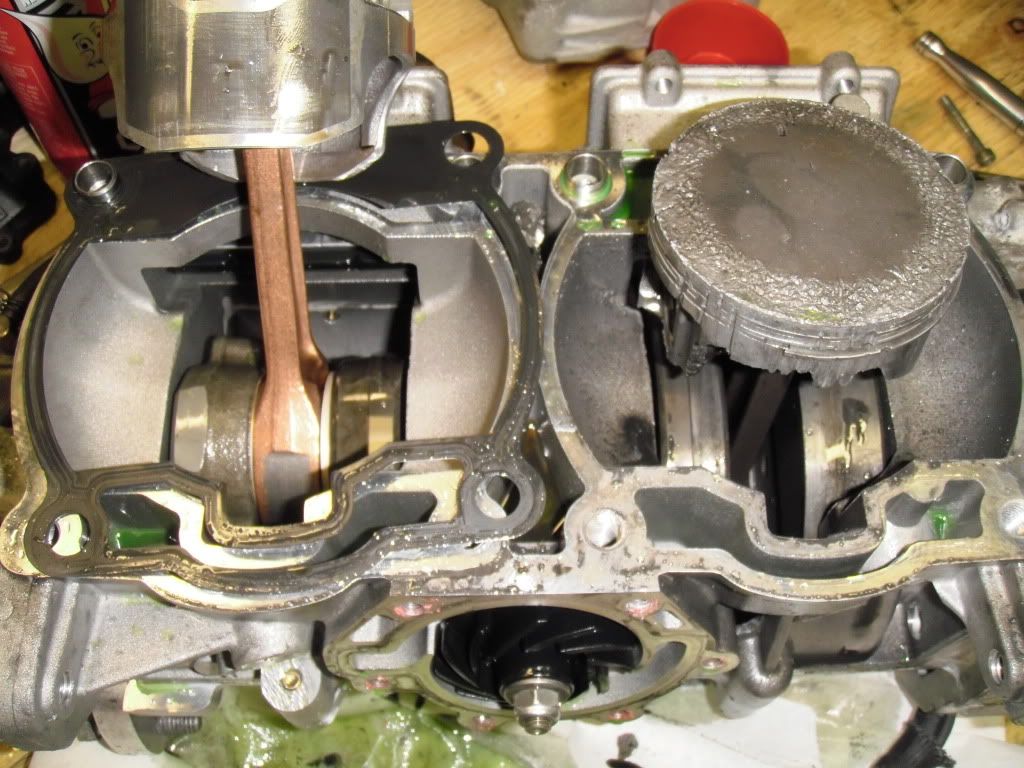

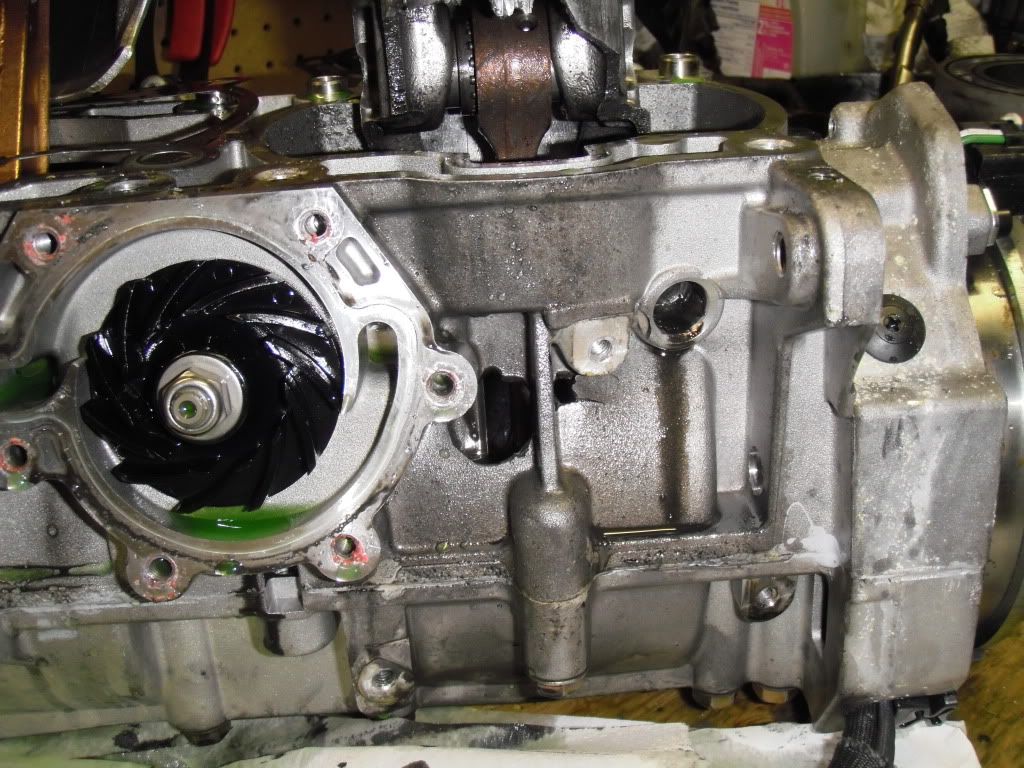

i bought this blown up from a guy, and this would be the 2nd time this engine has grenaded on me in the last 10miles. i thought i would post some pics caution some of these might make your wallet hurt, i know mine does.

i have replaced both reeds, cases, crank with the larger taper, new pistons spi, cylinders, heads slp, and this happens... im pretty sure it happen since i put it into reverse trying to get it off the truck.

next i will trying oem 06 pistons, new injectors, new reeds again, new cylinders, new heads again,

anything eles you guys suggest while im at it... im getting really depressed about this motor, i just wanna ride it.

i have replaced both reeds, cases, crank with the larger taper, new pistons spi, cylinders, heads slp, and this happens... im pretty sure it happen since i put it into reverse trying to get it off the truck.

next i will trying oem 06 pistons, new injectors, new reeds again, new cylinders, new heads again,

anything eles you guys suggest while im at it... im getting really depressed about this motor, i just wanna ride it.