M

Makaialaska

New member

Baddd Bearing

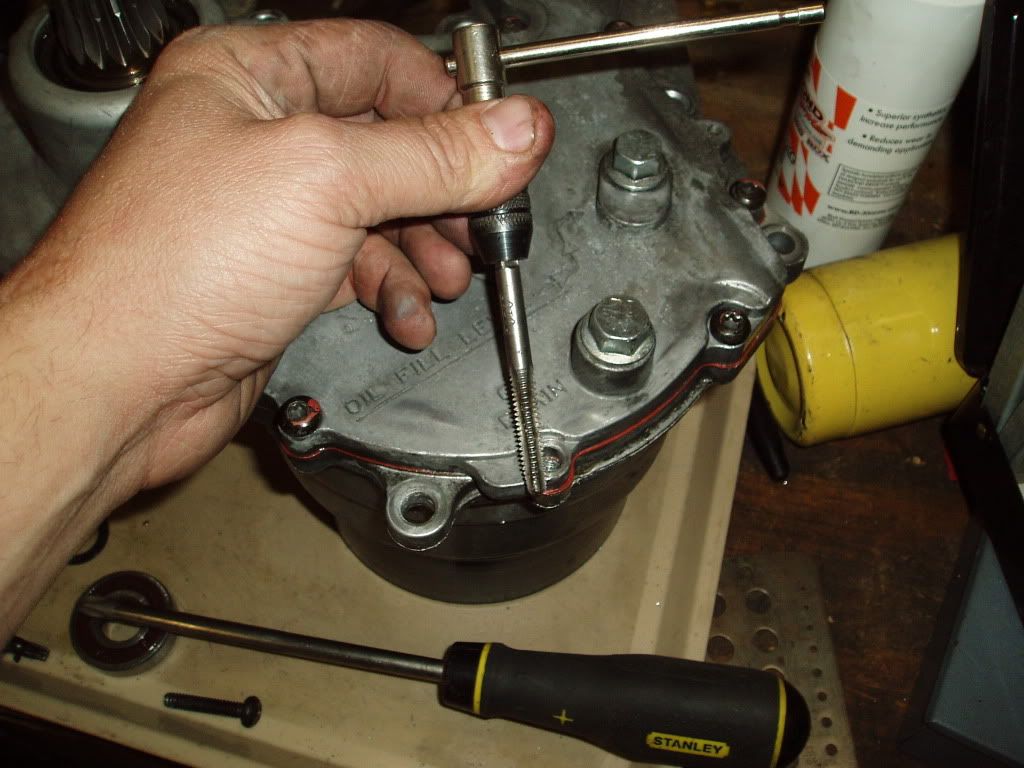

Thanks to you guys on this forum I checked mine today, I found my bearing was toast. The spacer had pushed up into the bearing and was had the seal riding on it. No cage left in the bearing. My dealer had not heard of this and no word from AC, I am going to put a 5203 in but was trying to justify taking the whole dd out and cleaning it. Looking for any input. I also have a 600 m and was wondering does this apply to that too? Changing the oil does not find this, my dealer said to change it and if no metal good to go. I checked anyway and found the bad bearing. Pic attached, sorry if i am usually a lurker but this is a real problem so I thought I should post. 300 easy miles and this shouldnt happen. Don.

Thanks to you guys on this forum I checked mine today, I found my bearing was toast. The spacer had pushed up into the bearing and was had the seal riding on it. No cage left in the bearing. My dealer had not heard of this and no word from AC, I am going to put a 5203 in but was trying to justify taking the whole dd out and cleaning it. Looking for any input. I also have a 600 m and was wondering does this apply to that too? Changing the oil does not find this, my dealer said to change it and if no metal good to go. I checked anyway and found the bad bearing. Pic attached, sorry if i am usually a lurker but this is a real problem so I thought I should post. 300 easy miles and this shouldnt happen. Don.