Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

09 Dragon 800 SLP clutch offset tool question??

- Thread starter dub

- Start date

It should be pushed toward the jackshaft bearing.

Sorry, this info is with the polaris tool!It should be pushed toward the jackshaft bearing.

R

Ron

ACCOUNT CLOSED

Is the offset measured with the clutch pushed tward the bulkhead or pulled toward you? This is in regards to secondary float.

I have heard/read a lot of conflicting thoughts..

Thanks

You set the offset by pulling the clutch toward the tool and then set float by letting it float toward the bulkhead. The Polaris service manual has it different-says to set it against the tool and then remove wahers behind the bolt to float away from the chasis.

I double checked my info from a very reliable source at Carl's Cycle, after getting it first from the tech at Carl's that sets up new sleds. Maybe I'll check again it seems that Polaris should be able to get this correct.

Edit: Offset is 17mm or .670 floating .030 to .050 toward the bulkhead.

Last edited:

D

dub

Well-known member

Thanks Ron, I called SLP and they said they "think" it's pushed to the bulkhead? With their tool the TSS-04 is supposed to be .140 away from the the inside edge of the tool to the outside of the clutch surface. I did set the float to .035 but unfortunately I set the offset with the clutch pushed in..

Ron , thanks for all the info you have provided in this forum. If you are willing, next time you call Carls talk to Chris and ask him if the PS47477 should be aligned with the driven held in or out. He told me to push in toward the bulkhead and set float with outer washers. I talked to him about 2 weeks ago and at that time he was pretty sure pushing in was correct. Maybe they can talk and come to a consensus. Thanks again, Ron.

Just eye-ball it.

D

dub

Well-known member

Cool, now 4 ways!!

Just got off the phone with somebody else at SLP, they now say to hit the offset dimension specified with the clutch sitting in the middle of your offset?? So instead of being forward or back, I need to rest it in the middle? A guy could really screw this up based on who he wants to listen to.

Clutch Alignment Tool

TSS-04 Instructions

1. Adjust belt deflection to 1.25". (Refer to Polaris service manual for further instructions on belt

deflection)

2. Remove drive belt.

3. Install notched end of clutch alignment tool (marked B in the diagram) over the fixed sheave of

the primary clutch (marked A in the diagram). Set arm of alignment tool (marked C and D) so

that it lies flush with the outboard of the secondary clutch (marked E).

Alignment specification without SLP Torque Arm/Push Arm

When alignment is correct, there should be a gap of .140" between point D on the

alignment tool and the outboard of the secondary clutch. Between point C on the

alignment tool and the outboard side of the secondary clutch, there should be .100" gap .

Alignment specification with SLP Torque Arm/Push Arm

When alignment is correct, there should be a gap of .100" to .120" between point D

on the alignment tool and the outboard side of the secondary clutch. Between point C on

the alignment tool and the outboard side of the secondary clutch, there should be .100"

gap .

4. If after checking clutch alignment it has been determined that an adjustment at point “D” is

needed, it can be done by loosening all motor mounts and gradually twisting the motor until the

desired alignment is achieved. If an adjustment at point “C” is needed, it can be done by adding or

removing jack shaft shims.

5. Tighten all mounts back to the manufacturer’s specification.

6. Adjust secondary clutch side to side free play on jackshaft. Optimum free play should be

between .020" and .040".This can be checked by measuring the amount of movement that the

secondary clutch has when mounted on the jack shaft. Adjustments can be made by adding or

removing jack shaft shims or clutch bolt shims.

Starting Line Products, 743 Iona Rd., Idaho Falls, ID. 83401

Sales (208)529-0244, Tech (208)524-3397, Fax (800)621-2893, Int. Fax (208)529-9000

Just got off the phone with somebody else at SLP, they now say to hit the offset dimension specified with the clutch sitting in the middle of your offset?? So instead of being forward or back, I need to rest it in the middle? A guy could really screw this up based on who he wants to listen to.

Clutch Alignment Tool

TSS-04 Instructions

1. Adjust belt deflection to 1.25". (Refer to Polaris service manual for further instructions on belt

deflection)

2. Remove drive belt.

3. Install notched end of clutch alignment tool (marked B in the diagram) over the fixed sheave of

the primary clutch (marked A in the diagram). Set arm of alignment tool (marked C and D) so

that it lies flush with the outboard of the secondary clutch (marked E).

Alignment specification without SLP Torque Arm/Push Arm

When alignment is correct, there should be a gap of .140" between point D on the

alignment tool and the outboard of the secondary clutch. Between point C on the

alignment tool and the outboard side of the secondary clutch, there should be .100" gap .

Alignment specification with SLP Torque Arm/Push Arm

When alignment is correct, there should be a gap of .100" to .120" between point D

on the alignment tool and the outboard side of the secondary clutch. Between point C on

the alignment tool and the outboard side of the secondary clutch, there should be .100"

gap .

4. If after checking clutch alignment it has been determined that an adjustment at point “D” is

needed, it can be done by loosening all motor mounts and gradually twisting the motor until the

desired alignment is achieved. If an adjustment at point “C” is needed, it can be done by adding or

removing jack shaft shims.

5. Tighten all mounts back to the manufacturer’s specification.

6. Adjust secondary clutch side to side free play on jackshaft. Optimum free play should be

between .020" and .040".This can be checked by measuring the amount of movement that the

secondary clutch has when mounted on the jack shaft. Adjustments can be made by adding or

removing jack shaft shims or clutch bolt shims.

Starting Line Products, 743 Iona Rd., Idaho Falls, ID. 83401

Sales (208)529-0244, Tech (208)524-3397, Fax (800)621-2893, Int. Fax (208)529-9000

Eyeball method is always accurate. All these tools and processes seem so unnecessary and confusing.....people getting the wrong alignment bars etc...

R

Ron

ACCOUNT CLOSED

Ron , thanks for all the info you have provided in this forum. If you are willing, next time you call Carls talk to Chris and ask him if the PS47477 should be aligned with the driven held in or out. He told me to push in toward the bulkhead and set float with outer washers. I talked to him about 2 weeks ago and at that time he was pretty sure pushing in was correct. Maybe they can talk and come to a consensus. Thanks again, Ron.

This still bugs me it's fairly important to sled performance. I called Jack Struthers just to check again and got the same answer-after setting the offset you set float by removing washers behind the clutch letting the clutch float toward the chassis. The Polaris service manual says to remove from behind the bolt letting the clutch float away from the chassis. I let mine float toward the chassis but even after customizing washers & using some non Polaris ones I ended up with a little float each way. Using the washers available will only get you close. I also tried to double check by measuring the old way on the movable sheave but it cocks at an angle because of the single point belt deflection bolt so that just doesn't work.

Seems to me the Polaris tool and instructions are the easiest, most accurate except for the direction of float!!!

I had a brand new SLP clutch alignment tool directly from SLP in I.F. last week... it was way off spec (bent?)

Definitely going to buy the SPX (Polaris tool)... Much thicker with all the angles milled into it... looks like a much higher quality tool.

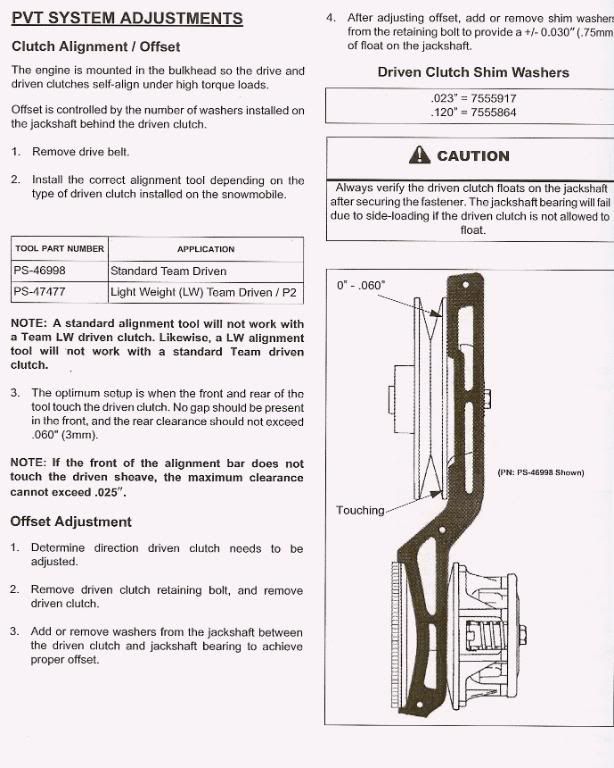

I'm curious about the physical differences between the two models [47477 and the 46998] ... I'm assuming that the diff is the offset measurement as the primary end would be the same and the surfaces should both be parallel ... an $80 tool compared to the $40 SLP... IMO worth every penny.

As I read it ... and as the tool would work agrees with the service manual... the offset is the distance of the fixed sheave from the tool which would be set by the shims "between the driven clutch and the jackshaft bearing" [Like Jack said]

Float is different than Offset...

First set the offset (step 3 in the manual above) and then adjust the float away from that offset (step 4)...

Personally I let it float both ways as Ron said on both the 900's and the Small block IQ's .... I float it .10 on both sides of the offset measurement.

=====

IMO... 1st find the zero mark for offset... 2nd set the outside float (washers under bolt) and 3rd subtract the same amount from the shims between the secondary and the jackshaft-bearing. You will have equal float.

I don't think, IMO, that the drivetrain is that sensitive to float as it is to correct clutch alignment.

Definitely going to buy the SPX (Polaris tool)... Much thicker with all the angles milled into it... looks like a much higher quality tool.

I'm curious about the physical differences between the two models [47477 and the 46998] ... I'm assuming that the diff is the offset measurement as the primary end would be the same and the surfaces should both be parallel ... an $80 tool compared to the $40 SLP... IMO worth every penny.

As I read it ... and as the tool would work agrees with the service manual... the offset is the distance of the fixed sheave from the tool which would be set by the shims "between the driven clutch and the jackshaft bearing" [Like Jack said]

Float is different than Offset...

First set the offset (step 3 in the manual above) and then adjust the float away from that offset (step 4)...

Personally I let it float both ways as Ron said on both the 900's and the Small block IQ's .... I float it .10 on both sides of the offset measurement.

=====

IMO... 1st find the zero mark for offset... 2nd set the outside float (washers under bolt) and 3rd subtract the same amount from the shims between the secondary and the jackshaft-bearing. You will have equal float.

I don't think, IMO, that the drivetrain is that sensitive to float as it is to correct clutch alignment.

Last edited:

Here's a little experiment for you. Put your secondary on the shaft (no bolt), apply some twisting force to the clutch and try to slide it.....it's TIGHT, will not move.

IMO you need proper alignment which is when the belt just kisses the inner sheave on the primary and belt/sheave clearance is all towards the outer sheave,....this applies to ANY sled with ANY combination of clutches.

Having any more float than what is necessary to allow the bolt to tighten and not preload the jackshaft bearing is actually a bad thing.

If the secondary floats all the way to one side and you pin the throttle, now the secondary is under load and will not move easily on the splines to get into proper alignment.....how much time does it spend misaligned if it can float outside of spec?? Just something to think about

IMO you need proper alignment which is when the belt just kisses the inner sheave on the primary and belt/sheave clearance is all towards the outer sheave,....this applies to ANY sled with ANY combination of clutches.

Having any more float than what is necessary to allow the bolt to tighten and not preload the jackshaft bearing is actually a bad thing.

If the secondary floats all the way to one side and you pin the throttle, now the secondary is under load and will not move easily on the splines to get into proper alignment.....how much time does it spend misaligned if it can float outside of spec?? Just something to think about

D

dub

Well-known member

Lot's of good stuff here but one question remains (for me anyway). As I said I am using the SLP tool, so what's to say they haven't built in the dimension for float in the tool. So they say .140 from the front of the sec. sheave to the tool what if they have already provided .010 of float. This would mean without float the outward dim would be 1.30...

It is just funny that I couldn't get a real answer from them??

I set mine up as they told me (toward the chassis then float out) and I didn't have any problems but I am still wondering!

It is just funny that I couldn't get a real answer from them??

I set mine up as they told me (toward the chassis then float out) and I didn't have any problems but I am still wondering!

I had a brand new SLP clutch alignment tool directly from SLP in I.F. last week... it was way off spec (bent?)

Definitely going to buy the SPX (Polaris tool)... Much thicker with all the angles milled into it... looks like a much higher quality tool.

I'm curious about the physical differences between the two models [47477 and the 46998] ... I'm assuming that the diff is the offset measurement as the primary end would be the same and the surfaces should both be parallel ... an $80 tool compared to the $40 SLP... IMO worth every penny.

As I read it ... and as the tool would work agrees with the service manual... the offset is the distance of the fixed sheave from the tool which would be set by the shims "between the driven clutch and the jackshaft bearing" [Like Jack said]

Float is different than Offset...

First set the offset (step 3 in the manual above) and then adjust the float away from that offset (step 4)...

Personally I let it float both ways as Ron said on both the 900's and the Small block IQ's .... I float it .10 on both sides of the offset measurement.

=====

IMO... 1st find the zero mark for offset... 2nd set the outside float (washers under bolt) and 3rd subtract the same amount from the shims between the secondary and the jackshaft-bearing. You will have equal float.

I don't think, IMO, that the drivetrain is that sensitive to float as it is to correct clutch alignment.

I agree, the polaris tool is good quality and offset should be pushed inward. I choose to have my float to the outside. I felt too that $80 is alot for the tool but worth it over the cheaper models that leave you wondering. Just my .02

For the $40 more... I'd get the Polaris/SPX tool for sure... and keep it in its own box and don't drop it.

Dub... Call Dustin Pancheri (spelling??) At SLP... he'll have the answer to your questions

Dub... Call Dustin Pancheri (spelling??) At SLP... he'll have the answer to your questions

X

XC700116

ACCOUNT CLOSED

Is any body using the Team alignment tool(s) seems to me that they should have it right if anybody does.

I was planning on buying the OEM Polaris one but I have a tss-04 and I have to do some work on a couple of 900's with the tss98 on them and don't want to drop $160 on alignment bars. This is also considering that the Tied is now coming to the market and I'm assuming that will most likely be yet another one.

The ones from Team are $50 ea and I would think they would do the job quite well but wondered what/if other's have found out differently.

I was planning on buying the OEM Polaris one but I have a tss-04 and I have to do some work on a couple of 900's with the tss98 on them and don't want to drop $160 on alignment bars. This is also considering that the Tied is now coming to the market and I'm assuming that will most likely be yet another one.

The ones from Team are $50 ea and I would think they would do the job quite well but wondered what/if other's have found out differently.

Is any body using the Team alignment tool(s) seems to me that they should have it right if anybody does.

I was planning on buying the OEM Polaris one but I have a tss-04 and I have to do some work on a couple of 900's with the tss98 on them and don't want to drop $160 on alignment bars. This is also considering that the Tied is now coming to the market and I'm assuming that will most likely be yet another one.

The ones from Team are $50 ea and I would think they would do the job quite well but wondered what/if other's have found out differently.

I have both the SLP and POLARIS GOLD PLATED (for TSS-04) tools.

The POLARIS tool has approx .070" of "kick" built into it, it is NOT parallel.

The SLP tool is parallel, works for both TSS-98 and TSS-04, WHEN USING the SLP tool on the TSS-04 (NARROWER lightweight SECONDARY) YOU HAVE TO MEASURE .120" TO .140" FROM THE TOOL TO THE SECONDARY.

TEAM makes (2) different tools ONE for the TSS-98 and another for the TSS-04

Similar threads

D

- Replies

- 1

- Views

- 1K

C

H

- Replies

- 17

- Views

- 2K