3. Pack A Punch

Narrowing up the 600 to fit into a Rev Gen4 chassis was an important priority but not the only priority. Ski-Doo wanted to continue the success it was enjoying with the 850, namely a smooth, broad powerband as well as be reliable season after season.

A smooth, broad powerband is important, but an engine, especially one in a sled that traverses the trees and drops into creek beds, needs to pack a punch. One shining characteristic of the 850 is instant throttle response. The 600 needed to have that same trait so the engineers used some of the same technologies. That means the 600R has the same E-Tec direct fuel injection system as the 850. Stab the throttle and it goes.

4. Pack A Punch – Part Two

The 600R is a little smaller than the 600 H.O. but it’s a tad more powerful—to the tune of 5 additional horsepower. The 600R with its displacement of 599.4cc is 5cc more than the 600 H.O. That all translates into 125 hp. And thanks to a new cranktrain and pDrive, Ski-Doo engineers said, the inertia is lower in the 600R, helping it to be faster at peak power.

The use of double reed valves (like what is used on the 850) also contributes to the power increase. “The W reed is very durable,” one Rotax engineer told us. It was using these reeds that allowed Rotax to shorten the intake length. It makes throttle response more crisp because there is not as much “volume” to fill up as the intake track is shorter.

5. One Is Better Than Two

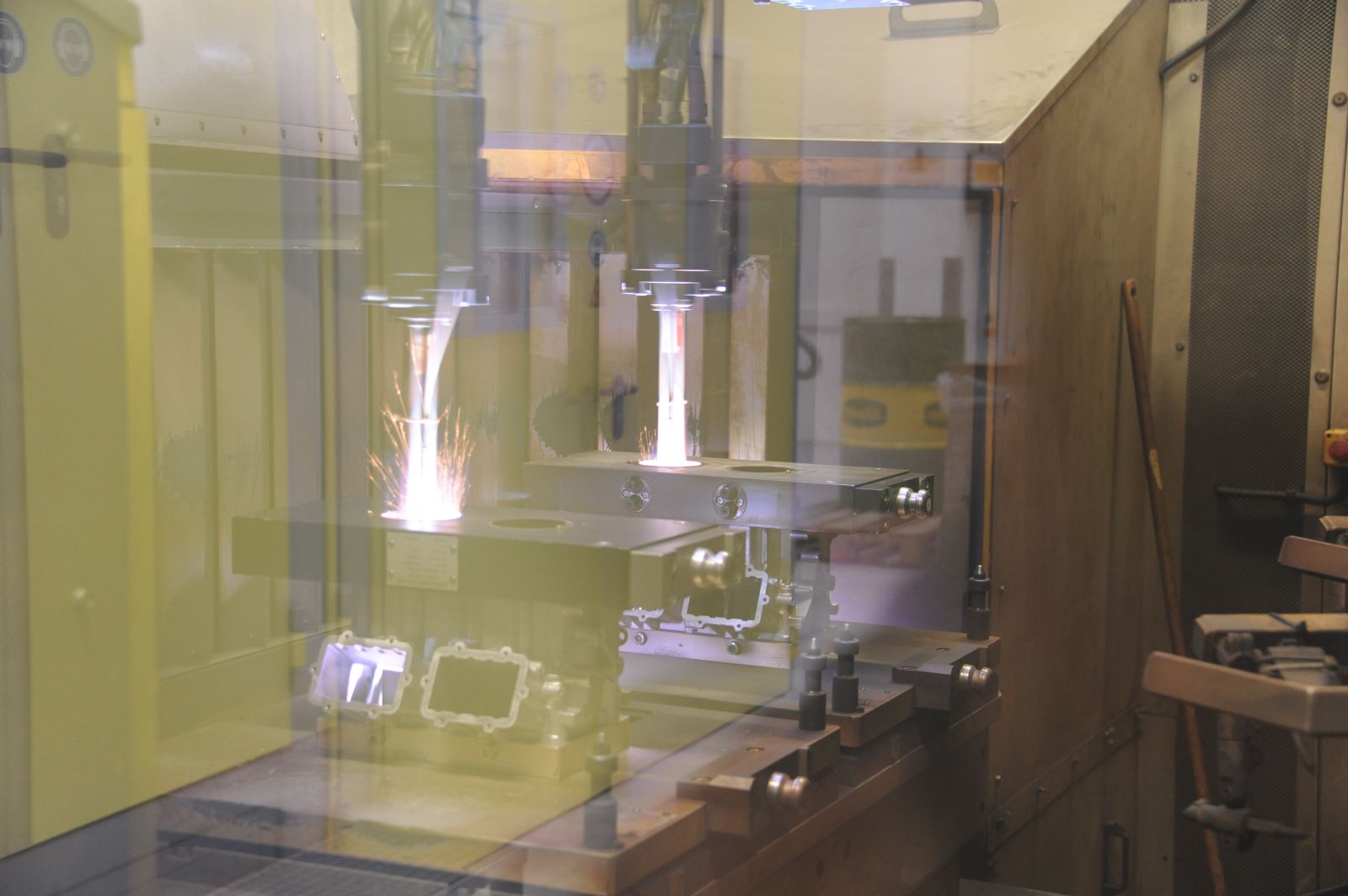

That might be a little misleading but now Rotax uses a mono-block cylinder design in the new 600R, which has two plasma-coated cylinders but one head. This design offers maximum transfer port efficiency as this design has been carefully matched to the crankcase. The mono-block design allows for more area for the transfer ports.

Rotax is the only company in the world that offers plasma coating on two-stroke cylinders with the process being key to the longevity of the cylinders. Six layers of plasma coating are applied to two-stroke cylinders which amounts to 300 microns total in all layers. Plasma coated cylinders hold oil better and provide for better lubrication of the cylinders than nikasil coating.

6. Shorter = Efficient

This time around we’re not talking about the narrower engine but the shorter intake track, again like what is found on the Rotax 850. The intake track is 35 percent closer, meaning not only is it shorter (less distance to travel) but it is straighter than the 600 H.O. track. Shorter and straighter translates into more efficiecy.