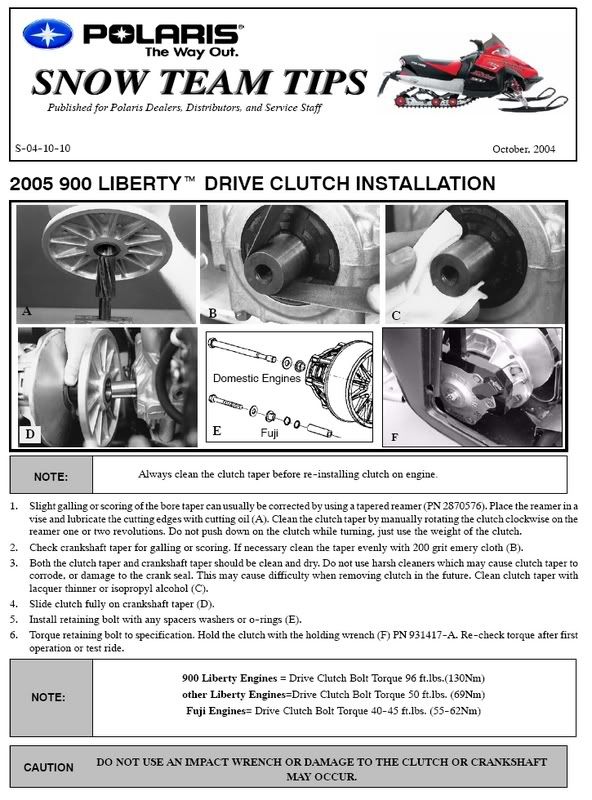

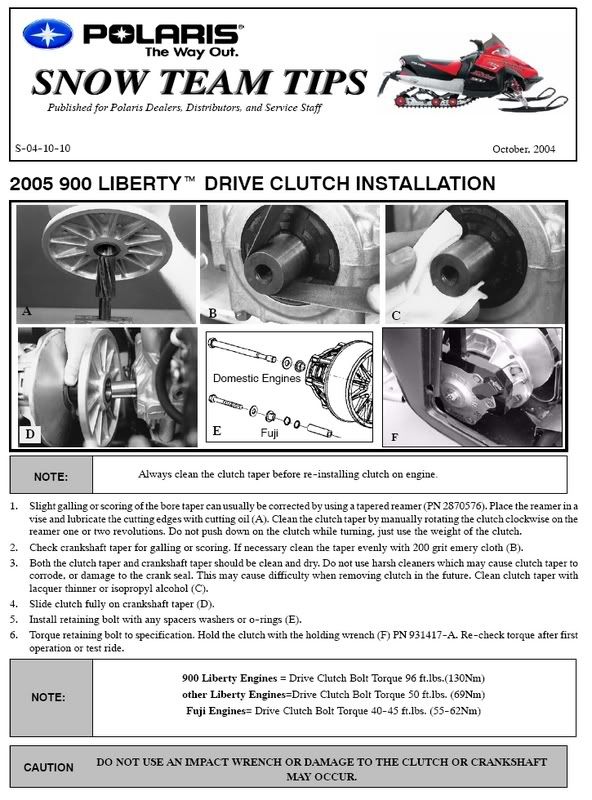

Check to see that the primary clutch bolt on your sled has not stretched and that the taper on the clutch bore and the PTO taper are in good shape before you run this year.

A stretched bolt will not reach torque spec.. It will have a slight hourglass shape to the part of the bolt that is the smallest diameter just above the threads.

This is especially true on the 900's that use a 96 ft lb spec and the new CFi sleds with an 80 lb torqe spec.

These instructions are for the 900 but, except for the torque rating, apply to all sleds.

Pre season attention in this area can help curb any downtime or catastophys during the season.

Now would also be the time to check/wash your belt, set the side clearance and belt deflection.

Good planning and maint. can give you a great season!!

here is the part number for the 900 clutch bolt 7518412 $18.57 at babbitts online

A stretched bolt will not reach torque spec.. It will have a slight hourglass shape to the part of the bolt that is the smallest diameter just above the threads.

This is especially true on the 900's that use a 96 ft lb spec and the new CFi sleds with an 80 lb torqe spec.

These instructions are for the 900 but, except for the torque rating, apply to all sleds.

Pre season attention in this area can help curb any downtime or catastophys during the season.

Now would also be the time to check/wash your belt, set the side clearance and belt deflection.

Good planning and maint. can give you a great season!!

here is the part number for the 900 clutch bolt 7518412 $18.57 at babbitts online

Last edited: