TECH TIPS

BEST BANG FOR THE BUCK MODS

Get a $25.00 annual subscription to DYNOTECH www.dynotechresearch.com

PC-5 from DYNOTECH Jim, Best $365.00 You'll spend, (585) 993-2777

Get the Autotune for an additional $250.00 or you can add that at a later date.

ALMOST FREE MODS

PRIMARY CLUTCH

1) Check your primary sheave side clearance, should be .010" to .015" with a BRAND NEW BELT, mine & my bud's were .070" from the factory. Increases acceleration and reduces the slamming effect onto the crank.

2) Send your clutch out for balancing, (Preferably after the above step has been completed) noticeably smoother running and extends crank life. SLP ($35.00) and others here on SnoWest can perform this service.

3) Install a new primary clutch spring @ the start of EVERY season.

SECONDARY

1) Install only ONE DELRIN washer under the spring cup (less than $5.00)

2) Install a new spring @ the start of every season

BOTH PRIMARY & SECONDARY

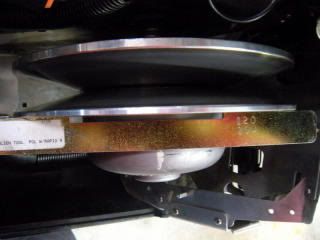

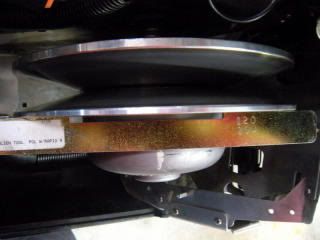

1) Align your clutches (center to center 11.5" EXACTLY, and check for engine crooked, pictures posted in the "link" below as to how the the alignment tool SHOULD contact the front and rear of the secondary) Check this using the SLP or TEAM tool, as the Genuine Gold Plated POLARIS tool has approx .070" of built-in "kick" which is NOT what you want. Check your alignment tool bar for "straightness" with a 3' or so carpenter's level, drywall "T" square, etc., and vernier calipers. mountainhorse reported (2) defective SLP tools. Just because it's NEW doesn't mean it's PERFECT!

A) WITH SLP PUSH LIMITER: 0 to .020" air gap @ the rear of the secondary, (with the front of the secondary touching the alignment bar)

B) WITHOUT SLP push limiter: .020" to .040" of air gap @ the rear of the secondary (with the front of the secondary touching the alignment bar)

You may have to slot the engine bracket(s) to get it PERFECT. On mine and my bud's 07 D7 we had to slot the Mag side engine bracket almost 3/8" to straighten things out. A picture of the Mag side engine bracket is in the link below, do this step ONLY if neccesary! Double check your c/c measurements after you get the engine "straight" and then slot BOTH engine brackets an EQUAL amount (if necceasry) to obtain the 11.5" center to center EXACTLY.

2) Check and adjust the offset after the above has been completed. This is E-Z to do, just adjust shims on the secondary shaft until the secondary touches the alignment bar. You want approx .030" of free play as well.

3) Lightly sand both the primary and secondary clutches with 180 grit sandpaper perpendicular to the way the belt rides and wipe down with lacquer thinner. Mark the primary with a fat black marker, make a few full throttle runs, and see where your belt rides up to on the clutch.

4) Wash/scrub (plastic bristle brush) your BRAND NEW belt w/soap & hot water, and let dry overnight, sounds weird but it removes the "mold release" compound that would otherwise would get smeared all over your nice clean clutches.

T.P.S. CHECKING & RE-SETTING PROCEDURE (Don't overlook this, easier than you think, don't just trust the dealer to "check" this with their digital wrench)

1) Build a tester for $10.00 with parts from Radio Shack, look @ the "INCREASING YOUR IQ" thread @ the top of the IQ forum, all the info is there. Then go to the 900 Section, there's a neat video that walks you through the process. Thanks to mountainhorse and the full monte for providing that info.

2) When setting the T.P.S. on C.F.I.'s, the throttle valves MUST BE FULLY CLOSED, then set it @ .70 volts +/-.01 volts for the 600/700/800

3) After that, turn the idle speed screw until the voltmeter reads .94 - .95 volts +/- .01 but this varies with model.

4) Using an analog style volt meter, gradually open and close the throttle and watch the voltmeter move gradually, erratic readings indicate a faulty T.P.S.

OTHER: OIL PUMP CALIBRATION, CHAIN TENSION, TRACK TENSION, ENGINE LIMITER, OTHER PERFORMANCE TIPS

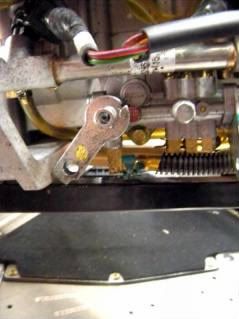

1) Check your oil pump calibration, mine was 38:1 stock, 1 1/4 to 1 1/2 turns on the 10mm adjuster nuts and it's 57:1 now for the last 1200 miles. Oil pump marks are suppose to align @ the 3:00 position as a starting point. Red dot on the case has a short (1/4" long) horizontal mark on it as does the oil pump arm, these are suppose to line up @ idle AS A STARTING POINT, and fine tune from there until you achieve the desired 55:1- 60:1 gas/oil ratio. Picture of the oil pump posted below.

2) Check your chain case tension, adjust it to where the chain almost touches the back of the case with finger pressure. While you're in the chain case, place a metal straight edge across the sprockets to make sure they're EXACTLY in line. Shim with 1" I.D. "Automotive valve spring shims" available from auto cylinder head rebuilding shops, Summit Racing, etc. Same shims also work on the secondary shaft for getting the offset "dialed in".

3) Run your track looser that POLARIS specs, approx 1" to 1 1/2" sag just sitting there on the stand.

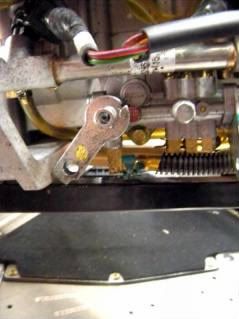

4) Install the SLP push arm engine limiter on the MAG side, approx 20 minute installation, only 2 holes to drill, SLP Part # 23-63, $42.95 Picture posted below.

5) Check Ski alignment, 1/8" toe out is preferred

6) Place a small piece of duct tape over your headlight adjuster knob, prevents water, snow, and ice from being ingested into your engine.

7) Remove your air box and wipe down the seam area with lacquer thinner and duct tape the seam, prevents Kevlar dust particles from being ingested into your engine.

8) Plug the exhaust purge hoses coming off the exhaust valves, this makes it like the 2001-2004 set-ups and definitely improves acceleration by allowing the exhaust valves to open sooner. An added benefit is the hot exhaust that was "held back" in the engine is released sooner, thereby effectively reducing internal engine temps.

9) Install a simple 1/4" shut off (available @ hardware stores) onto the P.T.O. side cylinder head, where the coolant line heats up the throttle bodies, this comes stock on 2007 Ski-Doo 800 and other models

10) Clean your exhaust valves and bores, they're dirtier & gummier than you realize. While you're there check the bellows for small rips and tears.

DEBATEABLE

SLP Big Air Kit and (4) Flo-Rites, ($42.95 + 4 X $19.95+ $122.00) E-Z to install, I just didn't notice any difference, that's all.

WASTE OF $$$$$$$$$$ I.M.O.

V-FORCE reeds, Maybe ever so slightly more responsive on it's best day, definitely NOT worth the $258.00 and a lot of installation time. Many riders have reported durability issues, as in after only one season. One more reason to not buy 'em.

Hope this helps, have a GREAT season!!!!!!

BEST BANG FOR THE BUCK MODS

Get a $25.00 annual subscription to DYNOTECH www.dynotechresearch.com

PC-5 from DYNOTECH Jim, Best $365.00 You'll spend, (585) 993-2777

Get the Autotune for an additional $250.00 or you can add that at a later date.

ALMOST FREE MODS

PRIMARY CLUTCH

1) Check your primary sheave side clearance, should be .010" to .015" with a BRAND NEW BELT, mine & my bud's were .070" from the factory. Increases acceleration and reduces the slamming effect onto the crank.

2) Send your clutch out for balancing, (Preferably after the above step has been completed) noticeably smoother running and extends crank life. SLP ($35.00) and others here on SnoWest can perform this service.

3) Install a new primary clutch spring @ the start of EVERY season.

SECONDARY

1) Install only ONE DELRIN washer under the spring cup (less than $5.00)

2) Install a new spring @ the start of every season

BOTH PRIMARY & SECONDARY

1) Align your clutches (center to center 11.5" EXACTLY, and check for engine crooked, pictures posted in the "link" below as to how the the alignment tool SHOULD contact the front and rear of the secondary) Check this using the SLP or TEAM tool, as the Genuine Gold Plated POLARIS tool has approx .070" of built-in "kick" which is NOT what you want. Check your alignment tool bar for "straightness" with a 3' or so carpenter's level, drywall "T" square, etc., and vernier calipers. mountainhorse reported (2) defective SLP tools. Just because it's NEW doesn't mean it's PERFECT!

A) WITH SLP PUSH LIMITER: 0 to .020" air gap @ the rear of the secondary, (with the front of the secondary touching the alignment bar)

B) WITHOUT SLP push limiter: .020" to .040" of air gap @ the rear of the secondary (with the front of the secondary touching the alignment bar)

You may have to slot the engine bracket(s) to get it PERFECT. On mine and my bud's 07 D7 we had to slot the Mag side engine bracket almost 3/8" to straighten things out. A picture of the Mag side engine bracket is in the link below, do this step ONLY if neccesary! Double check your c/c measurements after you get the engine "straight" and then slot BOTH engine brackets an EQUAL amount (if necceasry) to obtain the 11.5" center to center EXACTLY.

2) Check and adjust the offset after the above has been completed. This is E-Z to do, just adjust shims on the secondary shaft until the secondary touches the alignment bar. You want approx .030" of free play as well.

3) Lightly sand both the primary and secondary clutches with 180 grit sandpaper perpendicular to the way the belt rides and wipe down with lacquer thinner. Mark the primary with a fat black marker, make a few full throttle runs, and see where your belt rides up to on the clutch.

4) Wash/scrub (plastic bristle brush) your BRAND NEW belt w/soap & hot water, and let dry overnight, sounds weird but it removes the "mold release" compound that would otherwise would get smeared all over your nice clean clutches.

T.P.S. CHECKING & RE-SETTING PROCEDURE (Don't overlook this, easier than you think, don't just trust the dealer to "check" this with their digital wrench)

1) Build a tester for $10.00 with parts from Radio Shack, look @ the "INCREASING YOUR IQ" thread @ the top of the IQ forum, all the info is there. Then go to the 900 Section, there's a neat video that walks you through the process. Thanks to mountainhorse and the full monte for providing that info.

2) When setting the T.P.S. on C.F.I.'s, the throttle valves MUST BE FULLY CLOSED, then set it @ .70 volts +/-.01 volts for the 600/700/800

3) After that, turn the idle speed screw until the voltmeter reads .94 - .95 volts +/- .01 but this varies with model.

4) Using an analog style volt meter, gradually open and close the throttle and watch the voltmeter move gradually, erratic readings indicate a faulty T.P.S.

OTHER: OIL PUMP CALIBRATION, CHAIN TENSION, TRACK TENSION, ENGINE LIMITER, OTHER PERFORMANCE TIPS

1) Check your oil pump calibration, mine was 38:1 stock, 1 1/4 to 1 1/2 turns on the 10mm adjuster nuts and it's 57:1 now for the last 1200 miles. Oil pump marks are suppose to align @ the 3:00 position as a starting point. Red dot on the case has a short (1/4" long) horizontal mark on it as does the oil pump arm, these are suppose to line up @ idle AS A STARTING POINT, and fine tune from there until you achieve the desired 55:1- 60:1 gas/oil ratio. Picture of the oil pump posted below.

2) Check your chain case tension, adjust it to where the chain almost touches the back of the case with finger pressure. While you're in the chain case, place a metal straight edge across the sprockets to make sure they're EXACTLY in line. Shim with 1" I.D. "Automotive valve spring shims" available from auto cylinder head rebuilding shops, Summit Racing, etc. Same shims also work on the secondary shaft for getting the offset "dialed in".

3) Run your track looser that POLARIS specs, approx 1" to 1 1/2" sag just sitting there on the stand.

4) Install the SLP push arm engine limiter on the MAG side, approx 20 minute installation, only 2 holes to drill, SLP Part # 23-63, $42.95 Picture posted below.

5) Check Ski alignment, 1/8" toe out is preferred

6) Place a small piece of duct tape over your headlight adjuster knob, prevents water, snow, and ice from being ingested into your engine.

7) Remove your air box and wipe down the seam area with lacquer thinner and duct tape the seam, prevents Kevlar dust particles from being ingested into your engine.

8) Plug the exhaust purge hoses coming off the exhaust valves, this makes it like the 2001-2004 set-ups and definitely improves acceleration by allowing the exhaust valves to open sooner. An added benefit is the hot exhaust that was "held back" in the engine is released sooner, thereby effectively reducing internal engine temps.

9) Install a simple 1/4" shut off (available @ hardware stores) onto the P.T.O. side cylinder head, where the coolant line heats up the throttle bodies, this comes stock on 2007 Ski-Doo 800 and other models

10) Clean your exhaust valves and bores, they're dirtier & gummier than you realize. While you're there check the bellows for small rips and tears.

DEBATEABLE

SLP Big Air Kit and (4) Flo-Rites, ($42.95 + 4 X $19.95+ $122.00) E-Z to install, I just didn't notice any difference, that's all.

WASTE OF $$$$$$$$$$ I.M.O.

V-FORCE reeds, Maybe ever so slightly more responsive on it's best day, definitely NOT worth the $258.00 and a lot of installation time. Many riders have reported durability issues, as in after only one season. One more reason to not buy 'em.

Hope this helps, have a GREAT season!!!!!!

Last edited by a moderator: