I have a 900 which I think has a 05 piston on 1 side and a 06 on the other. Assuming I do, when I replace the 05 piston what should I do with the 06 piston? Do nothing, change rings, change piston and rings. I haven't checked compression on it yet.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

900 with 05 & 06 piston

- Thread starter saints5

- Start date

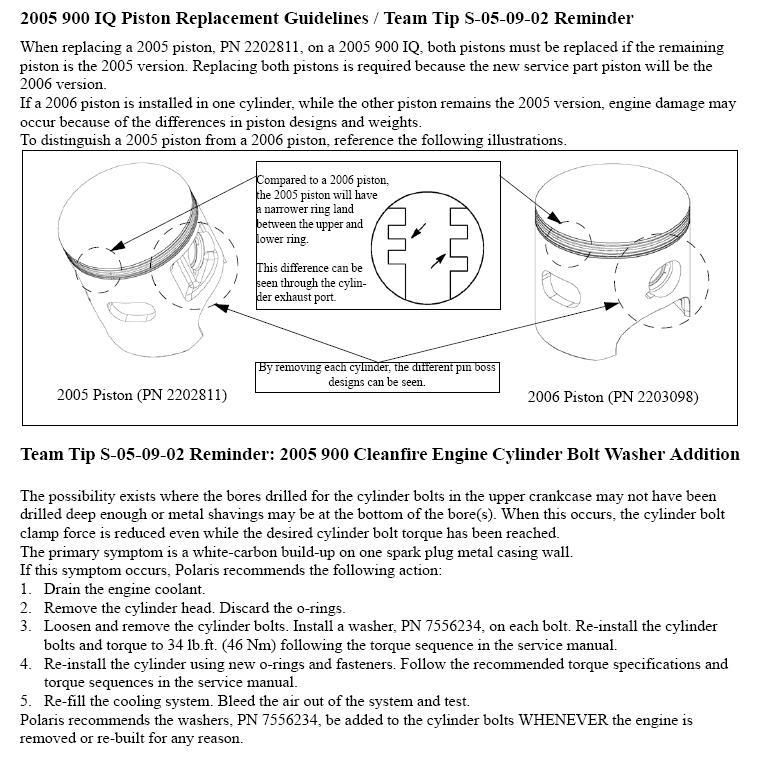

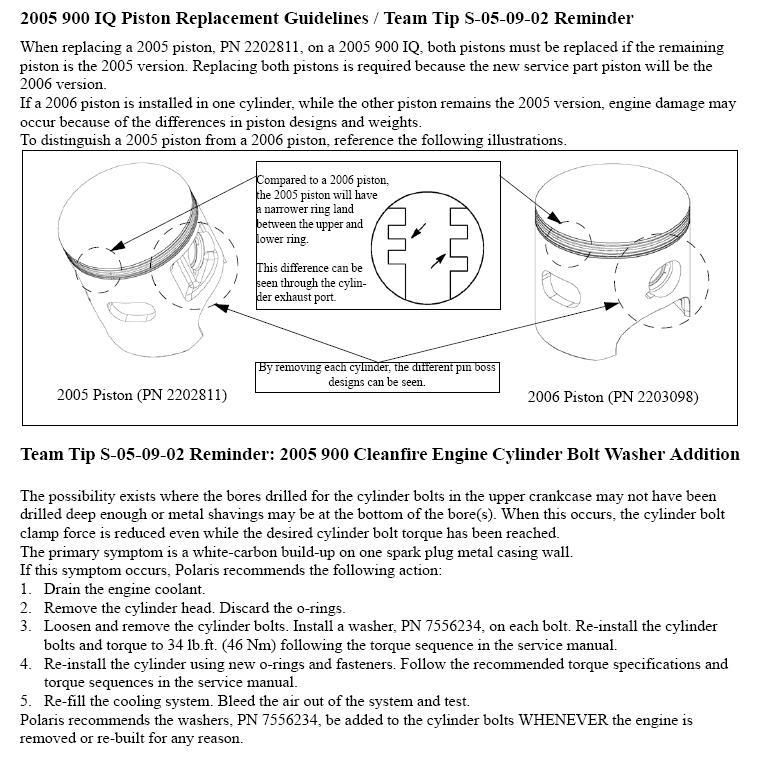

ONLY use the same year pistons with each other...

I doubt that you have 2 mis matched pistons.

I doubt that you have 2 mis matched pistons.

Last edited:

The reason I think I have mismatched pistons is that I have 2 900's. I lost a piston in my Switchback and over the weekend I thought I would repair it. So I bought 2 06 pistons. I was shocked to find a damaged 05 piston on 1 side and a perfectly fine 06 on the other. The same Polaris tech. has replaced 1 piston on my RMK. I'm assuming now that I have a 06 piston on 1 side already with about 1500 to 2000 mi. on it. So going back to my original question what should I buy? Since I don't know for sure I will probably buy 2 pistons, but for future reference when would just rings be replaced and when would a piston also be thrown in?

The difference between the cost of the rings versus the piston is like $50.00. I would put 2 new pistons in it and then you know what you got.

What Dave said ^^^

I have a 900 which I think has a 05 piston on 1 side and a 06 on the other.

It's not a "sales gimmic" Replace both pistons with the same year.

In fact, you can NO LONGER even get an 05 piston from a dealer unless they have old stock on the shelves from 3 yrs ago.

Assuming I do, when I replace the 05 piston what should I do with the 06 piston?

IMO, Change both pistons at the same time... run both with the same age of piston.

Do nothing, change rings, change piston and rings. I haven't checked compression on it yet.

Change both piston kits... which come with new rings... only use factory Polaris pistons.

Check your crank runout at the same time and phasing of the crank(if the piston strokes are 180 degrees seperated) which could be off now that you have run different mass pistons.

The same Polaris tech. has replaced 1 piston on my RMK.

He obviously cannot read the TSB's that Polaris has sent out and I'd have to wonder if he is a good choice to have working on your sled.

I'm assuming now that I have a 06 piston....

Do you know for sure?? I still find it hard to believe that you have a mis-match situation and the sled ran ok.

but for future reference when would just rings be replaced and when would a piston also be thrown in?

Replace both pistons when you are servicing them, always, IMO.

For reliability and the effort involved... I replace the pistons whenever the rings are worn beyond use... most of the time the cyl is beyond spec as well.

You will need to re hone the cyl for new rings (or new pistons with new rings)... (diamond hone)

On a higher mileage motor... you also need to inspect and measure the cylinders. If the nicasil is worn you will need have the cylinders reconditioned...

If there is Taper in the cylinder... it must be sent in for reconditioning.

Sometimes they are beyond repair and must be replaced

If there is damage or scratching to the cylinder in excess of .007" then the cyl will need to be welded.

There are NO oversized pistons available for these motors (other than big bore kits).

The pistons can often wear out before the rings, especially on motors with long stroke and high rod angularity like on the 900's

IF you need cyl reconditioning... I like Millenium Tech..

http://www.mt-llc.com

BTW... How many total miles on the engine and have you had any crank or case work done or warranty engine parts replacement?

I have a 900 which I think has a 05 piston on 1 side and a 06 on the other.

It's not a "sales gimmic" Replace both pistons with the same year.

In fact, you can NO LONGER even get an 05 piston from a dealer unless they have old stock on the shelves from 3 yrs ago.

Assuming I do, when I replace the 05 piston what should I do with the 06 piston?

IMO, Change both pistons at the same time... run both with the same age of piston.

Do nothing, change rings, change piston and rings. I haven't checked compression on it yet.

Change both piston kits... which come with new rings... only use factory Polaris pistons.

Check your crank runout at the same time and phasing of the crank(if the piston strokes are 180 degrees seperated) which could be off now that you have run different mass pistons.

The same Polaris tech. has replaced 1 piston on my RMK.

He obviously cannot read the TSB's that Polaris has sent out and I'd have to wonder if he is a good choice to have working on your sled.

I'm assuming now that I have a 06 piston....

Do you know for sure?? I still find it hard to believe that you have a mis-match situation and the sled ran ok.

but for future reference when would just rings be replaced and when would a piston also be thrown in?

Replace both pistons when you are servicing them, always, IMO.

For reliability and the effort involved... I replace the pistons whenever the rings are worn beyond use... most of the time the cyl is beyond spec as well.

You will need to re hone the cyl for new rings (or new pistons with new rings)... (diamond hone)

On a higher mileage motor... you also need to inspect and measure the cylinders. If the nicasil is worn you will need have the cylinders reconditioned...

Piston Inspection

Check piston for scoring or cracks in piston crown or pin

area. Excessive carbon buildup below the ring lands is an

indication of piston, ring or cylinder wear. For Liberty engines, measure piston outside diameter at a point 3/8” (10mm) up from the bottom of the skirt at a 90_ angle

to the direction of the piston pin.

NOTE: The piston must be measured at this point to provide accurate piston to cylinder measurements.

Subtract this measurement from the minimum cylinder measurement recorded previously when you recorded the cylinder measurements. If clearance exceeds the service limit, replaced if Nicasil plated and new pistons and rings installed.

Ring End Gap:

Position the ring 1/2" (1.3 cm) from the top of the cylinder

using the piston to push it squarely into place. Measure

installed gap with a feeler gauge at both the top and

bottom of the cylinder.

NOTE: A difference in end gap indicates cylinder

taper. The cylinder should be measured for

excessive taper and out-of-round.

Replace rings if the installed end gap exceeds the service limit.

Always check piston ring installed gap after reboring

a cylinder or when installing new rings.

If there is Taper in the cylinder... it must be sent in for reconditioning.

Sometimes they are beyond repair and must be replaced

If there is damage or scratching to the cylinder in excess of .007" then the cyl will need to be welded.

There are NO oversized pistons available for these motors (other than big bore kits).

The pistons can often wear out before the rings, especially on motors with long stroke and high rod angularity like on the 900's

IF you need cyl reconditioning... I like Millenium Tech..

http://www.mt-llc.com

BTW... How many total miles on the engine and have you had any crank or case work done or warranty engine parts replacement?

Last edited:

NOTE:

Honing a Nickasil cylinder is beyond the abilities of most people... special tools must be used and extreme care must be taken so that the nickasil is not damaged.

On 2-cycle engines... DO NOT use a ball hone for any reason as you will round the ports on the trailing edge of the hone process and probably damage the plating.

Honing a Nickasil cylinder is beyond the abilities of most people... special tools must be used and extreme care must be taken so that the nickasil is not damaged.

On 2-cycle engines... DO NOT use a ball hone for any reason as you will round the ports on the trailing edge of the hone process and probably damage the plating.

Cylinder Honing

The cylinder bore must be de-glazed whenever new piston

rings are installed.

A light honing with fine stones removes

only a very small amount of material. A proper

crosshatch pattern is important to provide a surface that

will hold oil, and allow the rings to seat properly. If the

crosshatch is too steep, oil retention will be reduced. A

crosshatch angle which is too shallow will cause ring vibration,

poor sealing, and overheating of the rings due to

blow-by and reduced contact with the cylinder wall. Service

life of the pistons and rings will be greatly reduced.

NOTE: A Nicasil cylinder can be lightly honed with a

diamond hone but can NOT be oversized.

Cleaning The Cylinder After Honing

It is very important that the cylinder be thoroughly cleaned

after honing to remove all grit material. Wash the cylinder

in a solvent, then in hot soapy water. Pay close attention

to areas where the cylinder sleeve meets the aluminum

casting (transfer port area). Use electrical contact cleaner

if necessary to clean these areas. Rinse thoroughly, dry

with compressed air, and oil the bore immediately with

Polaris Premium 2 Cycle Lubricant.

NOTE: Always check piston to cylinder clearance

and piston ring installed gap after honing or boring

is complete

Last edited:

BTW... How many total miles on the engine and have you had any crank or case work done or warranty engine parts replacement?

Total miles is 2800 mi.and only warranty work was the 1 piston replaced.

Do you know for sure?? I still find it hard to believe that you have a mis-match situation and the sled ran ok.

My switchback would have had close to 2000mi. with the mismatch.