Helping a buddy with an 05 900 who tore apart his topend and have a few questions

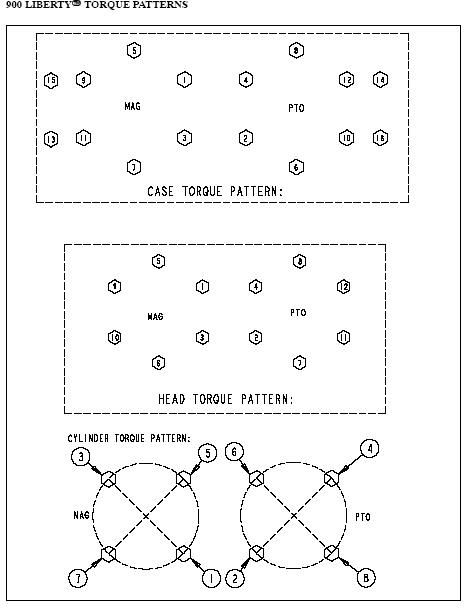

1) Torque specs for the cylinders and head bolts??

2) Ring gap spec?? Cylinder wall to piston spec (06 polaris oem pistons and rings)

3) Pistons have already been removed. Which way do the holes in the pistons face; go??

4) Any other advice

Thanks, Dave

1) Torque specs for the cylinders and head bolts??

2) Ring gap spec?? Cylinder wall to piston spec (06 polaris oem pistons and rings)

3) Pistons have already been removed. Which way do the holes in the pistons face; go??

4) Any other advice

Thanks, Dave