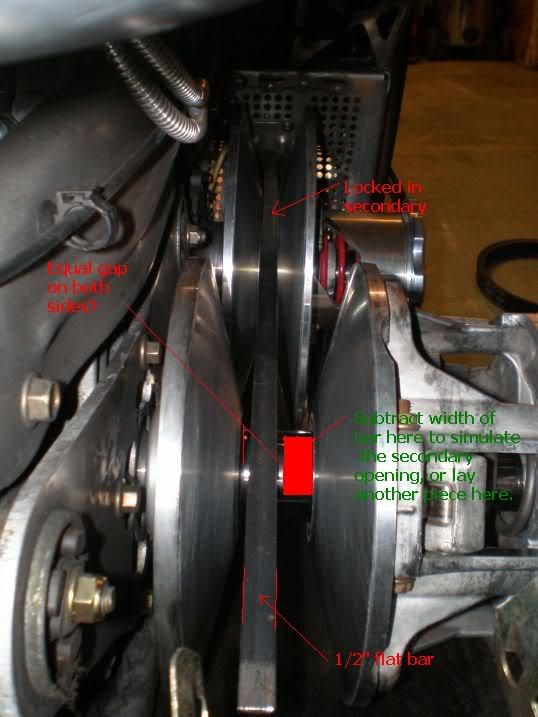

I know their is a lot of talk on here and the other forums about proper clutch alignment, which got me playing and doing some testing in the shop. Wouldn't this be the perfect clutch alignment to YOUR sled?

- You take a bar and lock it in your secondary sheaves so it runs up through the primary clutch.

- You subtract the width of your bar from the outer sheave on the primary shaft to simulate the primary being closed the same amount the secondary is open.

- You measure on both sides of your bar and shim the secondary accordingly to make them the same distance.

Would that not give you the exact, proper alignment to each other?

I have attached a picture here to show you. Sorry the quality is not good. For some reason when I saved it in my paint program it made the text blurry!

Aaron

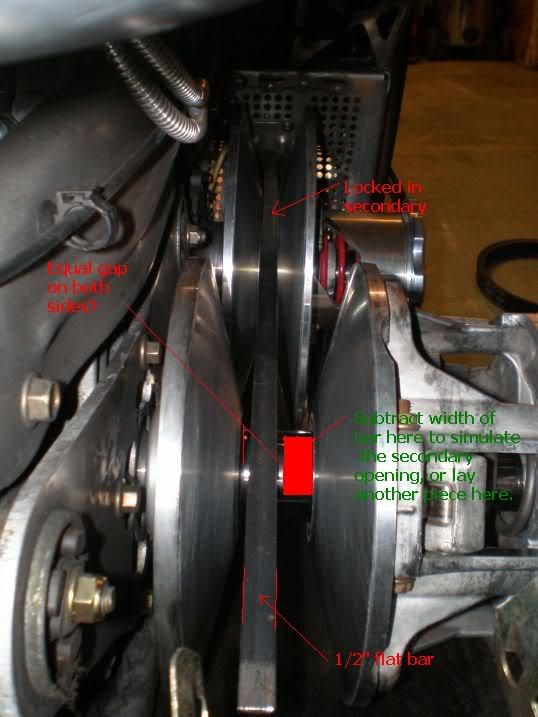

- You take a bar and lock it in your secondary sheaves so it runs up through the primary clutch.

- You subtract the width of your bar from the outer sheave on the primary shaft to simulate the primary being closed the same amount the secondary is open.

- You measure on both sides of your bar and shim the secondary accordingly to make them the same distance.

Would that not give you the exact, proper alignment to each other?

I have attached a picture here to show you. Sorry the quality is not good. For some reason when I saved it in my paint program it made the text blurry!

Aaron

Last edited: