Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weight/ Helix/ Gear setup

- Thread starter Abindl

- Start date

05 or 06?

What are the advantages of going with the 66/44/.46 v.s stock? Is that helix ran only for mountain riding or is it a very broad ranged helix??

N

Nelson

Well-known member

What are the advantages of going with the 66/44/.46 v.s stock? Is that helix ran only for mountain riding or is it a very broad ranged helix??

It is slightly steeper than stock and very good for back shift in the mountains.

Last edited:

N

Nelson

Well-known member

What elevation and riding are you doing?

My 06 900's were set up from 3000'-7500' with complete SLP performance package and my own clutching and gearing which seemed to work really well.

78g SLP MTX weights (74g with 2-2g rivets in each, 78g total)

Green/Pink SLP primary spring (160-340)

Team Lightweight Rapid Reaction Secondary TSS-04

66/44.46 and 66/42.46 Helix with Red/Black spring (140-240)

20/45 gears with custom chain

I think most people are running 11-74 Polaris weights, Green/Pink primary spring, 19/42 gearing, and you more than likely have the TSS-98 Team Secondary that people are also running the 66/44.46 Helix and Red/Black spring in their 05's. Hope this helps out a bit.

My 06 900's were set up from 3000'-7500' with complete SLP performance package and my own clutching and gearing which seemed to work really well.

78g SLP MTX weights (74g with 2-2g rivets in each, 78g total)

Green/Pink SLP primary spring (160-340)

Team Lightweight Rapid Reaction Secondary TSS-04

66/44.46 and 66/42.46 Helix with Red/Black spring (140-240)

20/45 gears with custom chain

I think most people are running 11-74 Polaris weights, Green/Pink primary spring, 19/42 gearing, and you more than likely have the TSS-98 Team Secondary that people are also running the 66/44.46 Helix and Red/Black spring in their 05's. Hope this helps out a bit.

Last edited:

N

Nelson

Well-known member

Its an 05 900. I have a 70-44-46? what do you think? I also only have black/ red spring, not red black.. what is the diffrence in tension?

Red/Black spring is 140-240

Black/Red spring is 155-222

what exactly is back shifting? And what are the differences that you feel of the 66/44 helix and stock?

the 66-44 helix (Part #420719) is the best all around helix for the 900 CFI engine bar none. It does not matter where you run the sled. if you have some HP increasing mods, use the second track with the 70 degree start angle.

you'll need to swap weights and primary springs for elevation changes. But the helix is spot-on for the 900's torque curve on both short and long-tracked sleds.

I am a flatland rider that plays in the deep when we get it, I am on a 2006 900 Switchback bone stock except the 66-44 helix. I also have guys running that same helix on 05-06 900 fusions for lake & trail riding. The clutches stay cool, belts do not explode anymore, and a few MPH gains have been made too.

Polaris really screwed the pooch when the clutched the 900 engines, They must have been looking at the P-85 charts and tried applying that logic to a team unit. It does not work that way at all.

you'll need to swap weights and primary springs for elevation changes. But the helix is spot-on for the 900's torque curve on both short and long-tracked sleds.

I am a flatland rider that plays in the deep when we get it, I am on a 2006 900 Switchback bone stock except the 66-44 helix. I also have guys running that same helix on 05-06 900 fusions for lake & trail riding. The clutches stay cool, belts do not explode anymore, and a few MPH gains have been made too.

Polaris really screwed the pooch when the clutched the 900 engines, They must have been looking at the P-85 charts and tried applying that logic to a team unit. It does not work that way at all.

Change the stock helix

Here is what has been working for me... I've refined it a bit.

Stock 900 with SLP can, no other mods (NO pipe,reeds,head, reflash etc)

All of this info is given assuming that your Belt side clearance on the primary is set to .010" - .020" with the belt you are using AND the deflection is set correctly.

All of the great clutching in the world wont mean squat if these things are not taken care of...

Deflection is easy, side clearance requires specialized tools and holding fixtures and must be done with the clutch removed from the sled.

Secondary

64-42 helix

2 delrin washers in the cup

RED-PINK secondary spring (140-260) [I switched from Red/Black...140-240]

Primary

First and foremost... the primary must be tight, have the faces smooth and be balanced.

11-68 weights

Polaris Almond spring (140-330) or the new spring sytem black-3342 (pn 7043342)

Gearing

19-42 for the 151" and 159"

19-43 for the 166" (requires a 76 pitch chain)

All of this is a bit of science and a lot of trial and error. Find what works for you.

IMO, on the 900's ONLY run the 3211115 belt. It is hands down the most heavy duty belt for these sleds... it only takes one belt blowing under heavy load (when the break most of the time) to snap a crank... The 115 belts usually outlast anything else out there.

===========

Nelson, Aren't you running an SLP pipe/reflash, high compression head, Reeds etc??

That would swing way more weight than a stock 900. and have different backshift character with the tall gearing and the super long track.

Your weights are heavier (78 mtx's = 74 gram 10 series) , but so is the spring.

The back shift will not be as responsive with the heavy weight heavy spring...

Even on the 166 x 2.4" track

I really like the 20-45 gearing (2.25:1) which rests squarely between the 19-42 and 19-43 gearing.... I'll bet that 166 track uses every bit of it!

Yours is still one of my favorite 900's out there!!

========================================================

Here is what has been working for me... I've refined it a bit.

Stock 900 with SLP can, no other mods (NO pipe,reeds,head, reflash etc)

All of this info is given assuming that your Belt side clearance on the primary is set to .010" - .020" with the belt you are using AND the deflection is set correctly.

All of the great clutching in the world wont mean squat if these things are not taken care of...

Deflection is easy, side clearance requires specialized tools and holding fixtures and must be done with the clutch removed from the sled.

Secondary

64-42 helix

2 delrin washers in the cup

RED-PINK secondary spring (140-260) [I switched from Red/Black...140-240]

Primary

First and foremost... the primary must be tight, have the faces smooth and be balanced.

11-68 weights

Polaris Almond spring (140-330) or the new spring sytem black-3342 (pn 7043342)

Gearing

19-42 for the 151" and 159"

19-43 for the 166" (requires a 76 pitch chain)

All of this is a bit of science and a lot of trial and error. Find what works for you.

IMO, on the 900's ONLY run the 3211115 belt. It is hands down the most heavy duty belt for these sleds... it only takes one belt blowing under heavy load (when the break most of the time) to snap a crank... The 115 belts usually outlast anything else out there.

===========

Nelson, Aren't you running an SLP pipe/reflash, high compression head, Reeds etc??

That would swing way more weight than a stock 900. and have different backshift character with the tall gearing and the super long track.

Your weights are heavier (78 mtx's = 74 gram 10 series) , but so is the spring.

The back shift will not be as responsive with the heavy weight heavy spring...

Even on the 166 x 2.4" track

I really like the 20-45 gearing (2.25:1) which rests squarely between the 19-42 and 19-43 gearing.... I'll bet that 166 track uses every bit of it!

Yours is still one of my favorite 900's out there!!

MTX™ weights allow you to run 4 grams heavier per weight than you would normally run with OEM weights (ie: if you have been running a 64 gram weight, you should use a 68 gram MTX™ weight).

========================================================

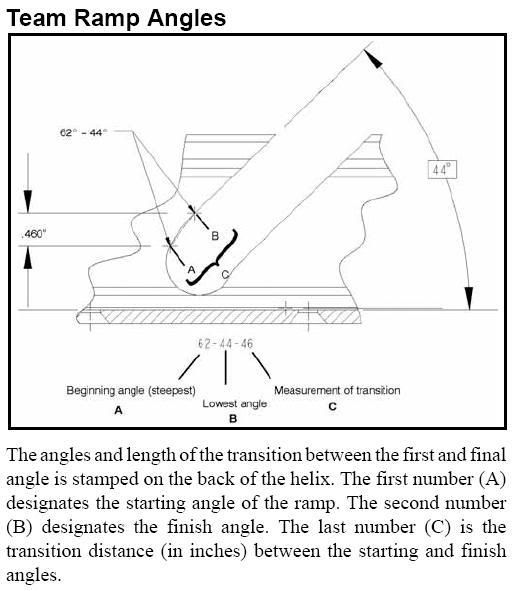

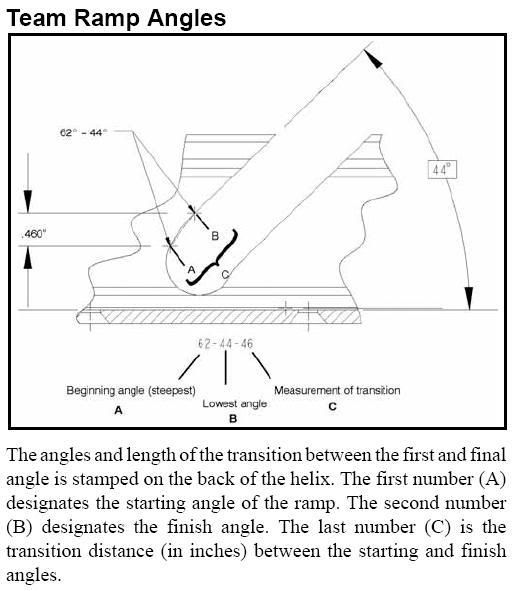

Back-Shifting

Back-shifting occurs when the track encounters an increased

load (demand for more torque). Back-shifting is a function of a

higher shift force within the driven clutch then within the drive

clutch. Several factors, including riding style, snowmobile

application, helix angles, and vehicle gearing determine how

efficient the drive system back-shifts. The desired engine

operating RPM should never fall below 200 RPM when the

drive system back-shifts.

Driven Helix

The helix cam is the primary torque feedback component within

the driven clutch, regardless of driven clutch type. The

beginning angle of the helix must transmit enough torque

feedback to the moveable sheave in order to pinch the drive belt

while minimizing belt slip. The flatter or lower the helix angle,

the more side force will be exerted on the moveable sheave,

while the steeper, or higher the helix angle, the less side force

will be exerted on the moveable sheave.

Great thread guys. I have a 06 900 switchback, changed out the track to a 2" shaved down to 1.75", timbersled air intake, and a Dynoport pipe and can. I am embarrased to say I can not remember which gear I changed out, but I did drop down the gearing, in other words to get out of the hole a little better. I put a clutch kit in it, but am not happy with it. I buddy of mine has the same sled but without the mods and put heavy hitter weights in it with good results. Based on me mostly boondocking in the U.P., what set-up for gearing and clutching would you recommend? Thanks in advance.

great thread! I went to the dealer to look into the 115 belt. I asked them about shimming. I'm running the 111 belt and have almost 900 miles on it. everyone says I have to shim it but the 115 belt is about .040 to .060 thinner(JUST LOOKING AT IT) what do I really have to do to go from a 111 belt to a 115? I want to check out my clutching and try to set it up like this thread says. how much is the helix worth to change? please help with belt??

N

Nelson

Well-known member

Eric, do you have a part number for the 64-42 Helix? I'm at Lake Tahoe and won't be home until next week and on the phone with my dealer yesterday trying to get one of these Helix's ordered for my buddies 05 900 with 151 to try out when I get back but they say they can't find it. This is for the TSS-98 secondary right? Its not a custom cut Helix is it? Did you mean 62/44.46 maybe?

Last edited:

Team # 420493

64/44 & 64/42 x .46" (Twin angle ER)

Where are you staying in Tahoe?? (my home turf)

64/44 & 64/42 x .46" (Twin angle ER)

Where are you staying in Tahoe?? (my home turf)

I am also changing from a 11 belt to a 15 belt and not sure what shimming is can someone tell me what that is and how to do it and where to get parts or what parts to get. thanks

as long as you guys are pulling apart your primary clutches, Check them to see if they need machining to close fully.

many of the 2005 clutches were machined wrong, and the could not fully shift out. Some had weights hitting the spider and binding, others needed material removed from the center so the sheaves could close all the way.

best scenario, send the clutch to "Indy Specialties" in Shakopee MN and have dan go through to make sure they are ok, and get it balanced by him. heck, you may as well send him both clutches, a new 1115 belt, tell him the engine mods you have, elevation you ride, your weight with riding gear, and have him do the whole package for you.

then send him the whole engine in the spring, get his crank and the cases fitted correctly and have a bulletproof bottom end with a 3-year warranty on it!

many of the 2005 clutches were machined wrong, and the could not fully shift out. Some had weights hitting the spider and binding, others needed material removed from the center so the sheaves could close all the way.

best scenario, send the clutch to "Indy Specialties" in Shakopee MN and have dan go through to make sure they are ok, and get it balanced by him. heck, you may as well send him both clutches, a new 1115 belt, tell him the engine mods you have, elevation you ride, your weight with riding gear, and have him do the whole package for you.

then send him the whole engine in the spring, get his crank and the cases fitted correctly and have a bulletproof bottom end with a 3-year warranty on it!

Similar threads

T

- Replies

- 5

- Views

- 279