B

Ben550

Well-known member

Construction an ultralight monoski snowmobile. It’s not really a snowbike because it’s not a modified motorcycle, and it has some utility aspect, very low riding position, allows it to pass under Maple Tubing better than a snowmobile. Possibility of carrying tools-snowshoes and reverse gear to be able to explore in dense woods without forcing.

In order to have even more places to have fun in the woods, sneak even more into narrow places with limited heights, SIDE hill or not than the Small-Doo. Instead of having to travel hours and hours on the road to find open terrain in the mountains and untouched.

I also can't wait to see the effect of the ski compacting the snow in front of the track a bit, compared to a snowmobile compacting and pushing snow under the skis, but this expended energy and traction is not used by the track that sees fresh snow.

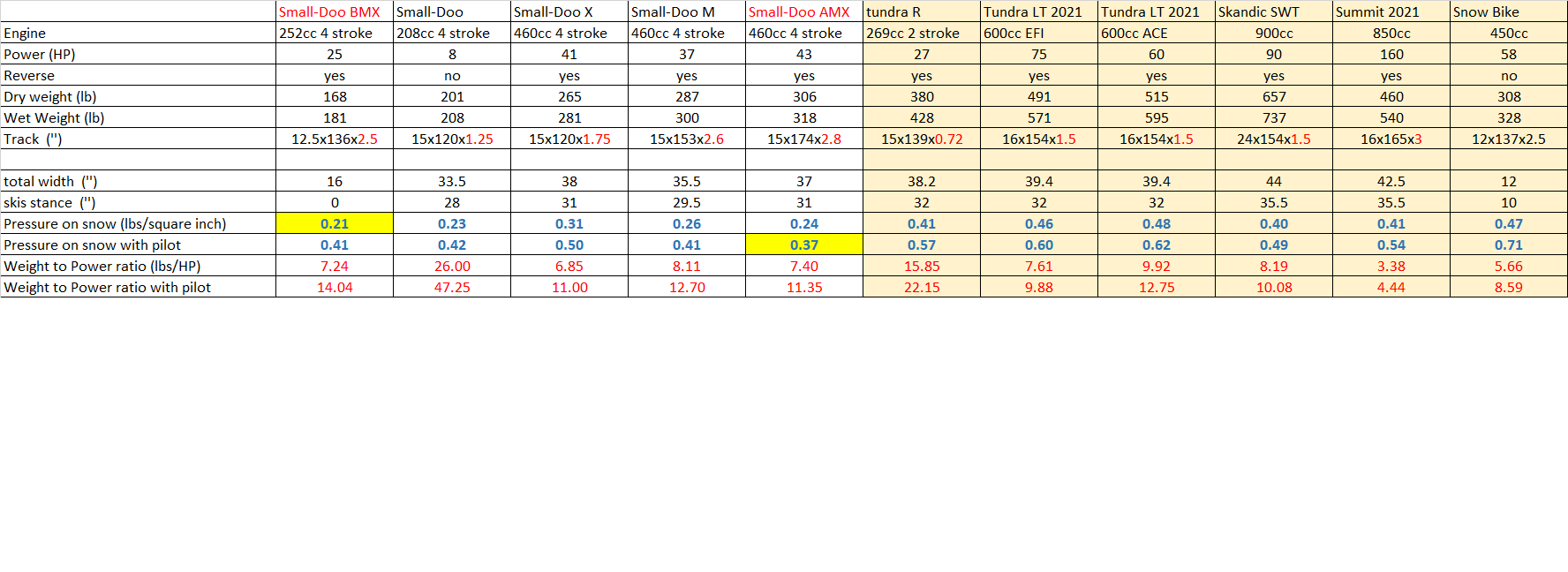

At 180.5lbs with gasoline, that's near half the weight of a 450 Snow bike with one the same length (137)

The rider's weight is on the track, unlike a snow bike whose weight is just in front of the track, which makes a big difference in traction and flotation at low speeds. This also allows you to have a very progressive attacking angel. Disadvantage, the ski has less bite given the low proportion of weight supported on it.

So although the Small-doo BMX track is small compared to off-road snowmobiles, the featherweight gives extremely low ground pressure.

At 180.5 lbs, it is about the same weight as my BW208 motorcycle which is extreme because we are talking about 2 small balloon tires vs a long track and the addition of a reverse gear.

It is also the same weight as a small competition motorcycle CRF150R and lighter than a CRF125F These bikes are surely more robust to withstand the mistreatment of the competition but we are still in the very small vehicle without track to have a comparable weight.

A Timberland kit weighs 137 ’’ weighs 121lbs at the rear (track suspension, tunnel and adapters) and 16lbs for skiing I couldn’t have built from that to get a total of 180lbs

The 136 "track with curved profile (2.5" center) is quite heavy with its stiff studs, 41lbs, almost double the weight of the frame. Too bad I am not equipped to vulcanize a track.

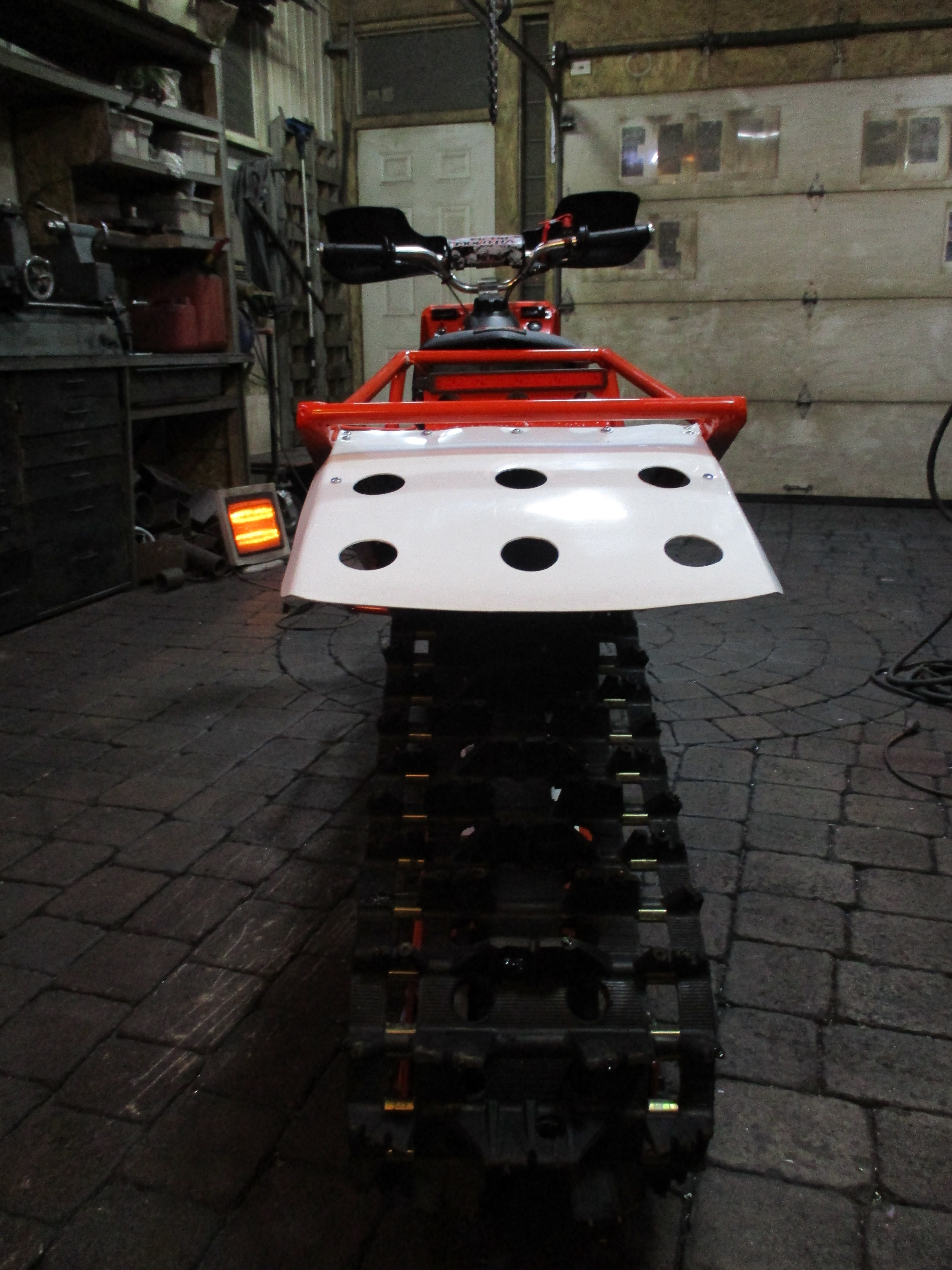

He had to have a line a style, despite it being unlike anything out there. Carbon fiber insertions between the structure, light and very ventilated side panels, which closes with a single push button, much faster than the multi panel systems, several clips that there are on Cie snowmobiles, they will prevent snow and ice to accumulate around the mechanics .. Bumper front to give continuity to the line and to have a good grip, it can be mounted alone in a peakup box (with a ramp) without the engine help.

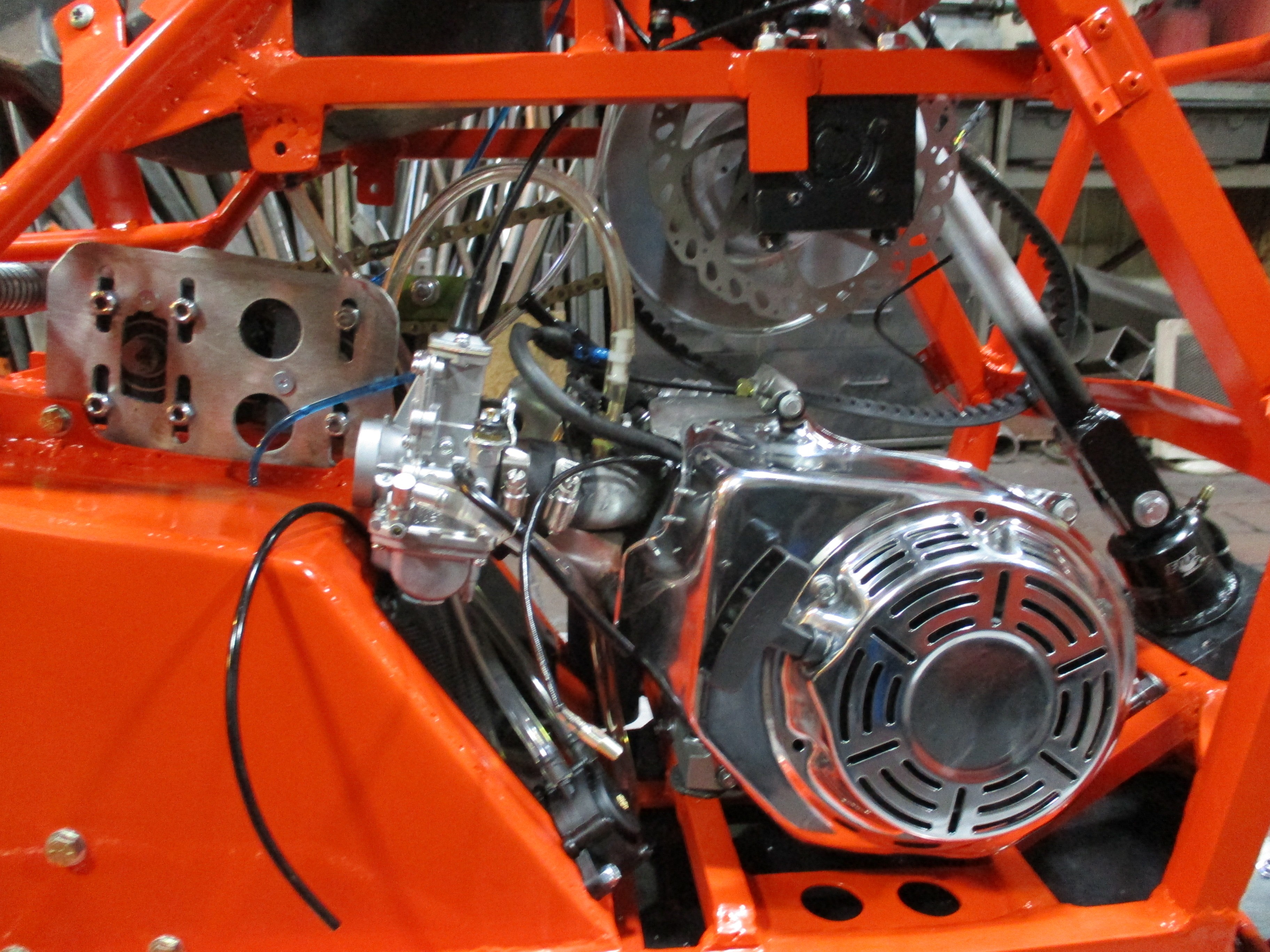

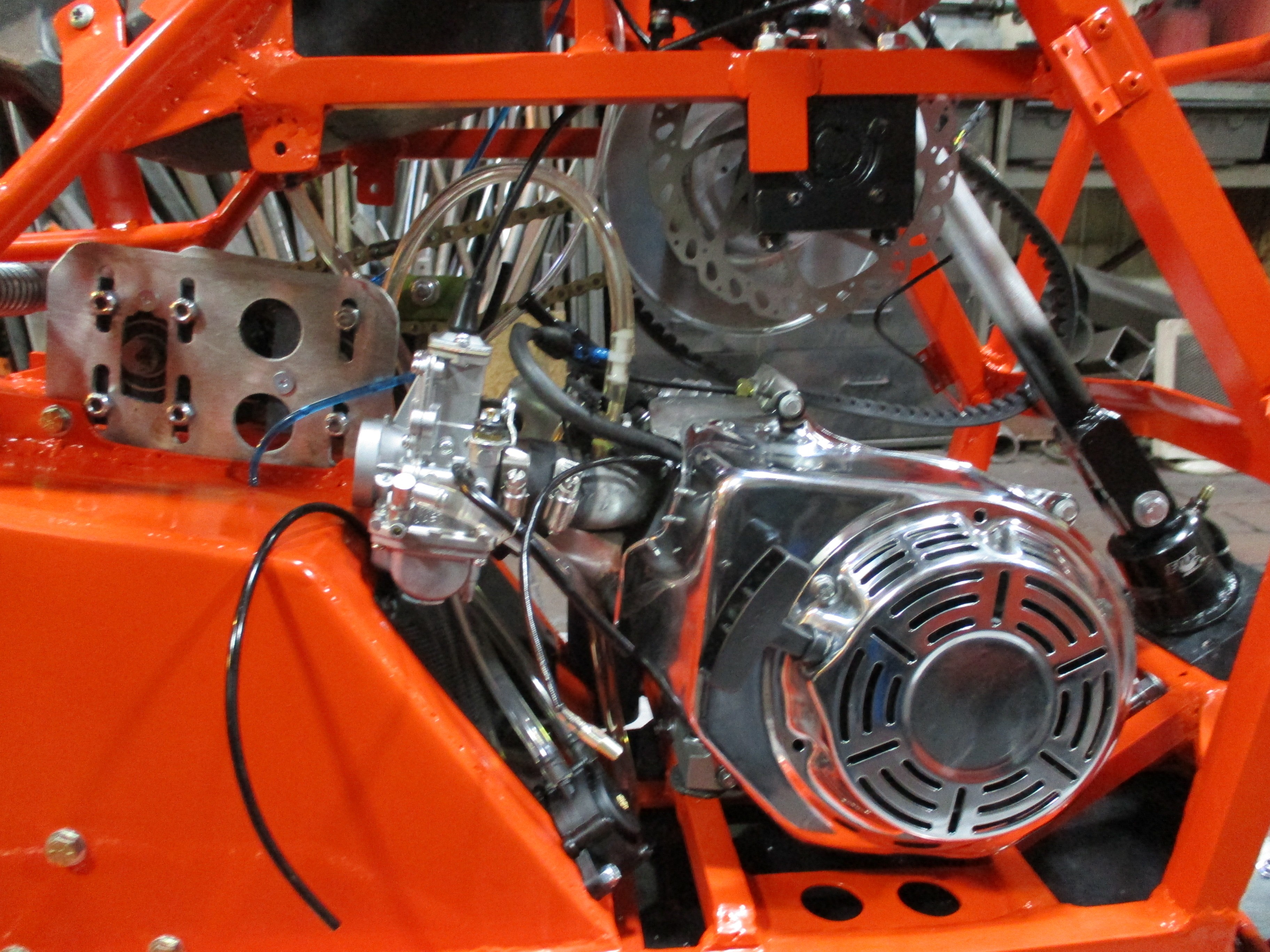

I had to use a small engine block to have an ideal distribution (sitting on the track, good angle of the handlebars, low seat, all the mechanical transmission that fits in 14 "wide!)

Engine parts Similar to a Honda GX200 which only has 6.5hp at 3600RPM, but it is a 3 '' big bore Tillottons base and crankshakt stroker which gives 252cc, I enlarged and changed the angle of the head to have a flow at 28 '' almost 3 times that of a GX200 head (the valves are also bigger) The compression ratio is much higher, all forged parts inside. So about 25hp at 7000 RPM.

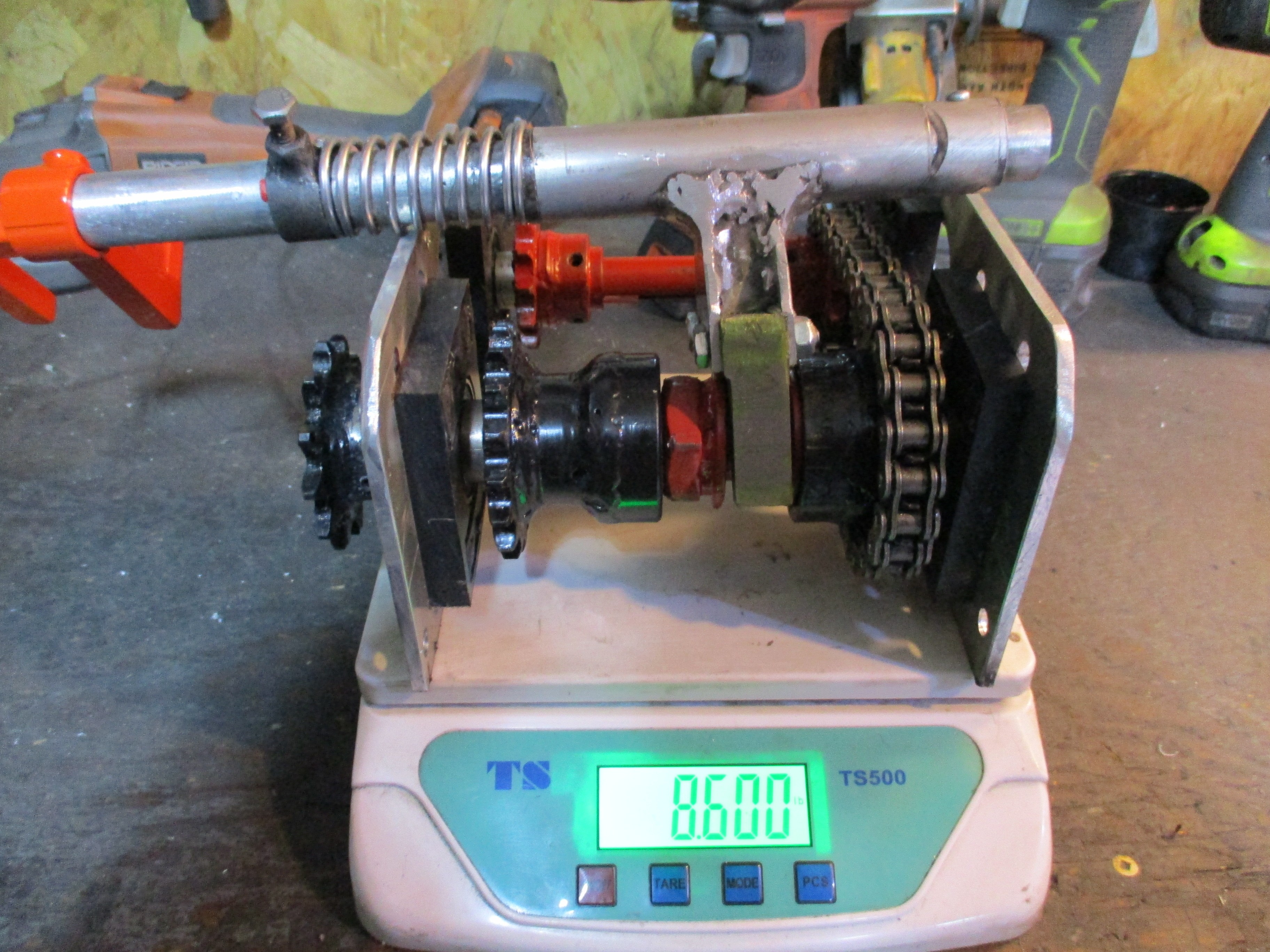

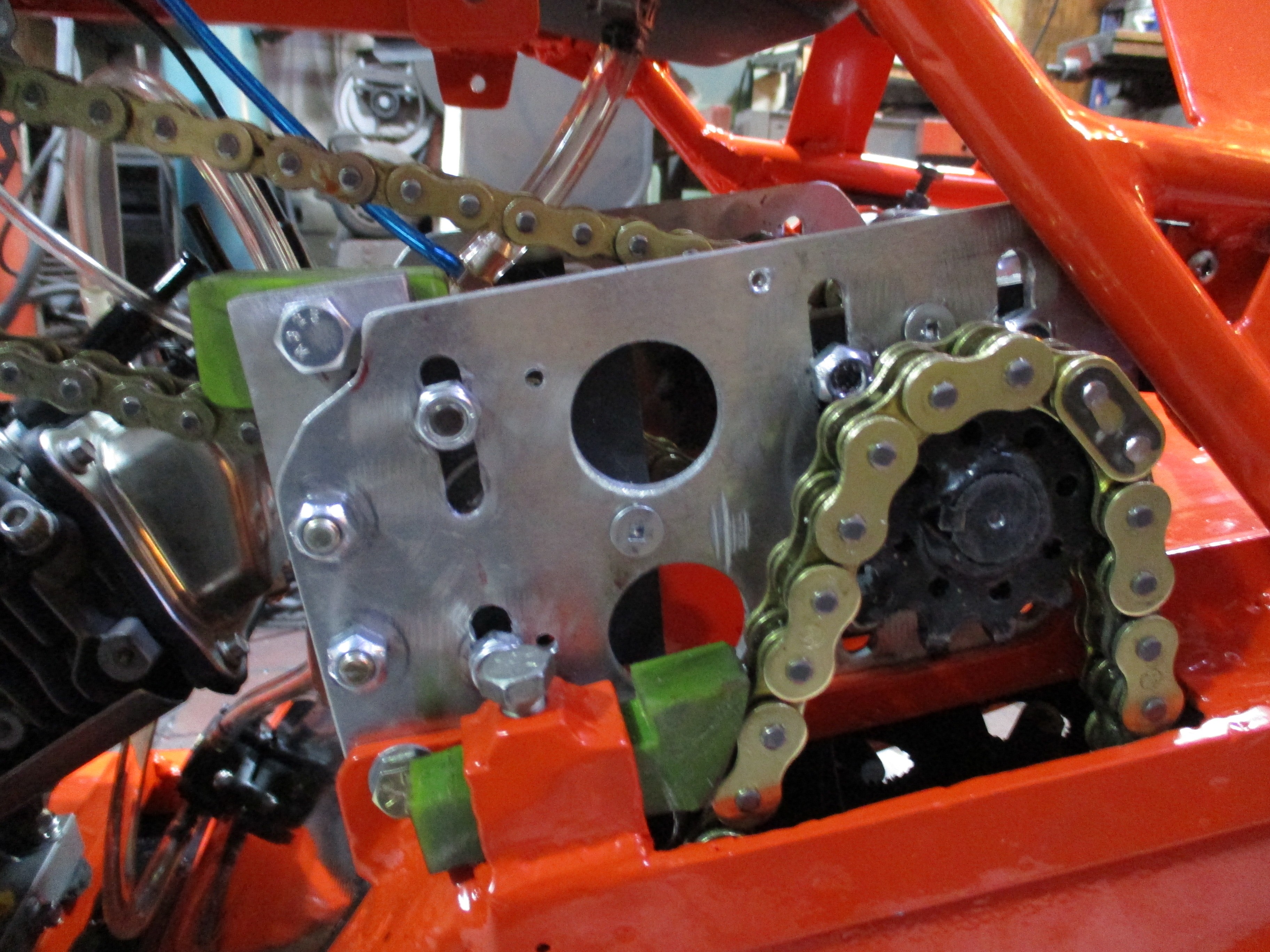

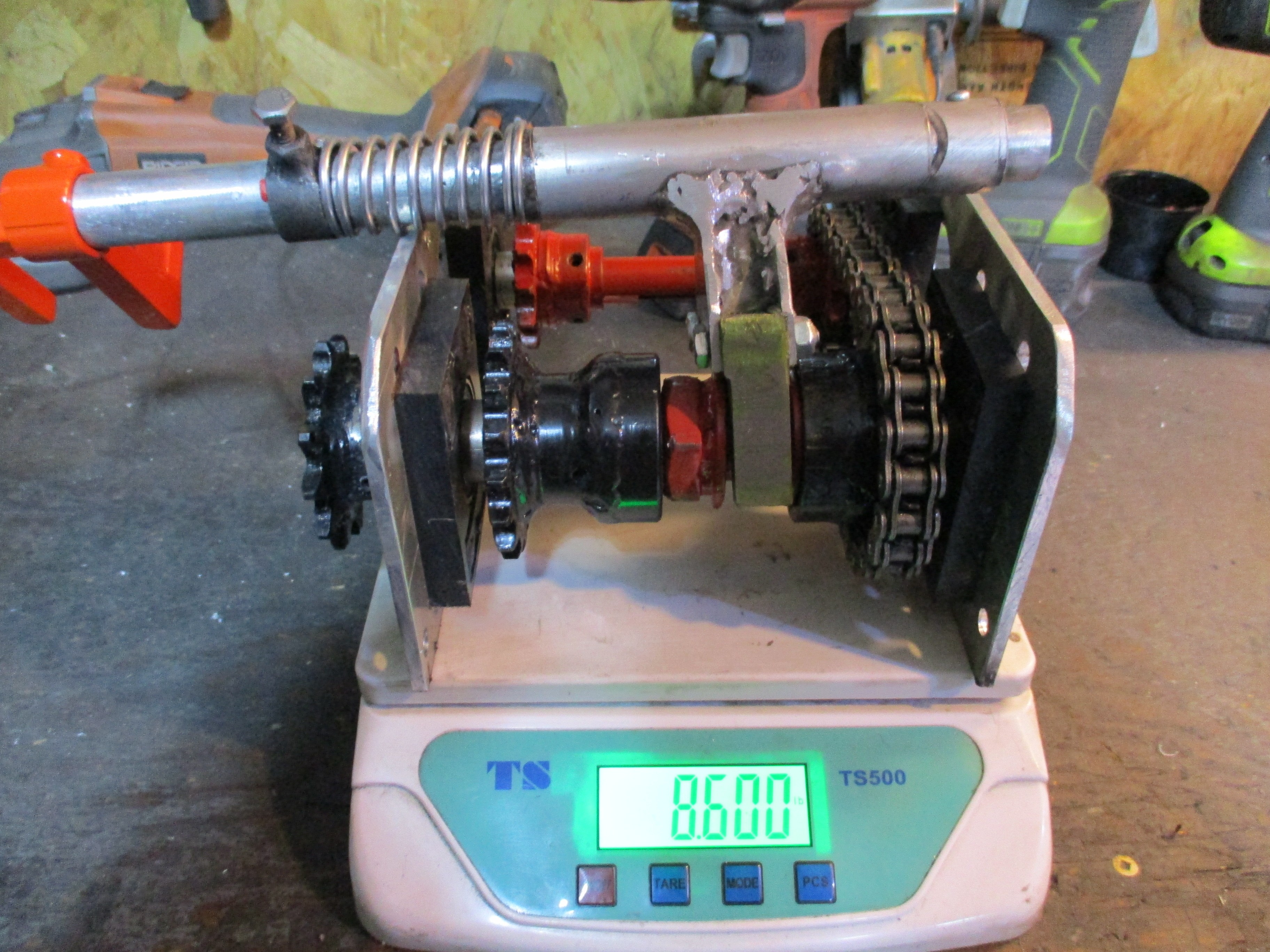

Home made front rear transmission, only the outside of the sprocket, chains and bearing were purchased. So a lot of small parts to build and a lot of adjustments. The whole thing weighs 8.5lbs, but if it had only been walked before it would have needed a much bigger socket at the bottom as there wouldn't have been any secondary gear, a good 2lbs more.

The rear drivetrain therefore adds 6.5lbs. These are X ring chains, so frequent oiling is not necessary. If there had been a strong enough lightweight drivetrain that would fit under the seat while still leaving room for the carburetor at a reasonable price, I would have bought it. A tiny lever that drives a cam allows you to switch from front to back.

The aluminum drive shaft, the UHMW bearing brackets and barred by small steel plates, which forgives small errors in parallelism and is much less heavy than Pillot bearings. There is less than 0.02 ’left between the components to keep the tunnel narrow without putting a chain case.

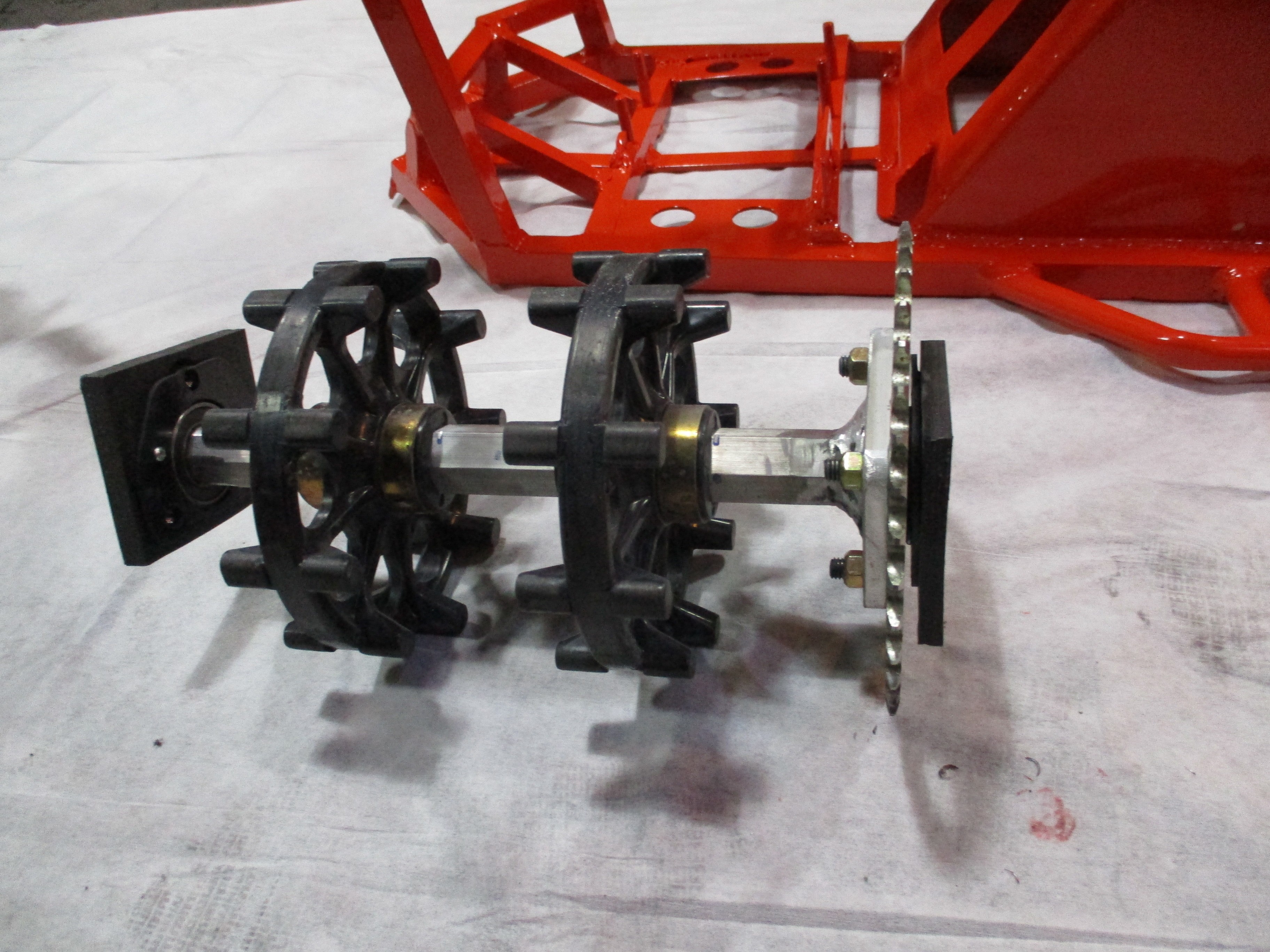

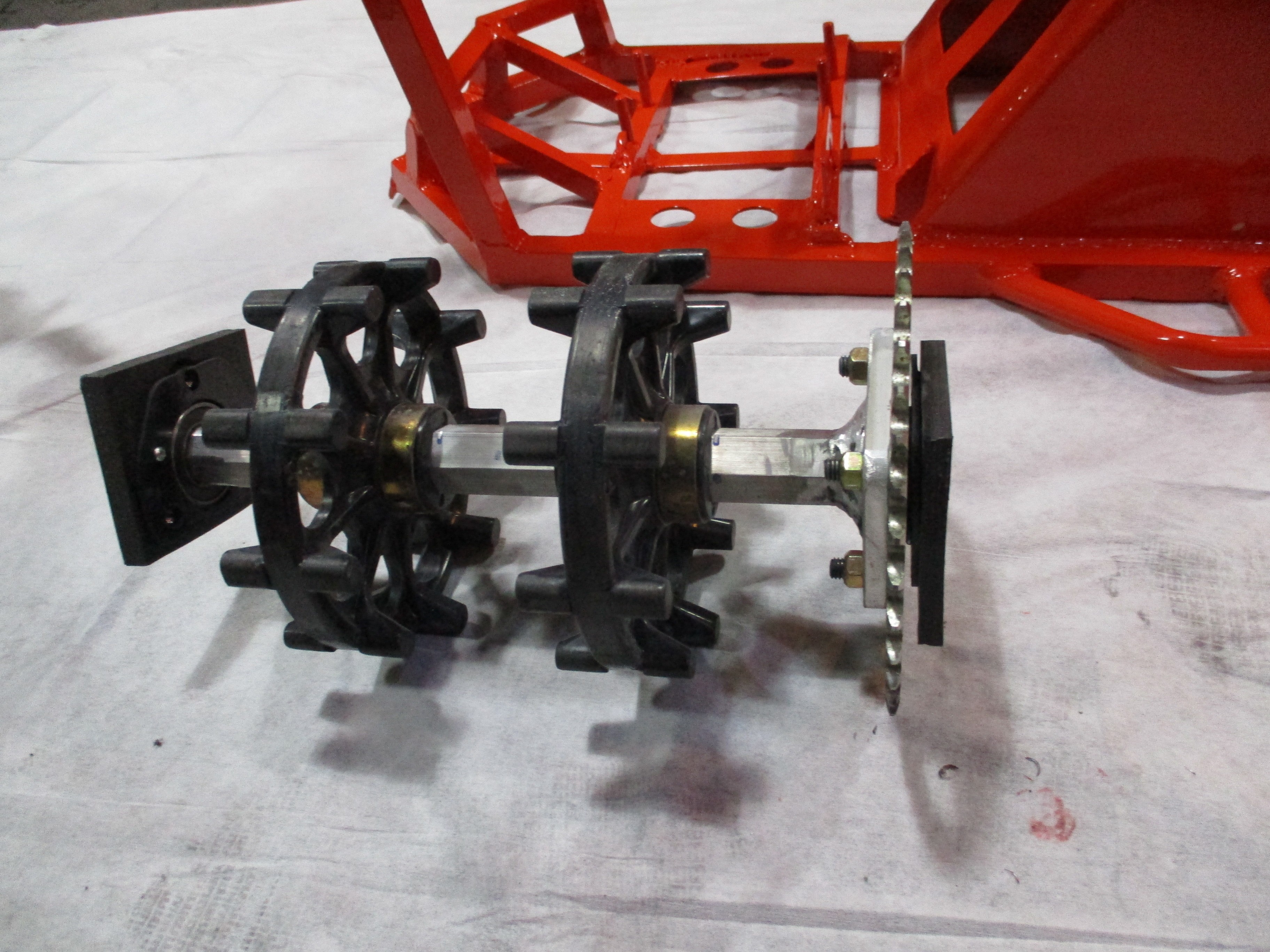

I made all the wheels to save a few lbs in total, with smaller than standard bearings.

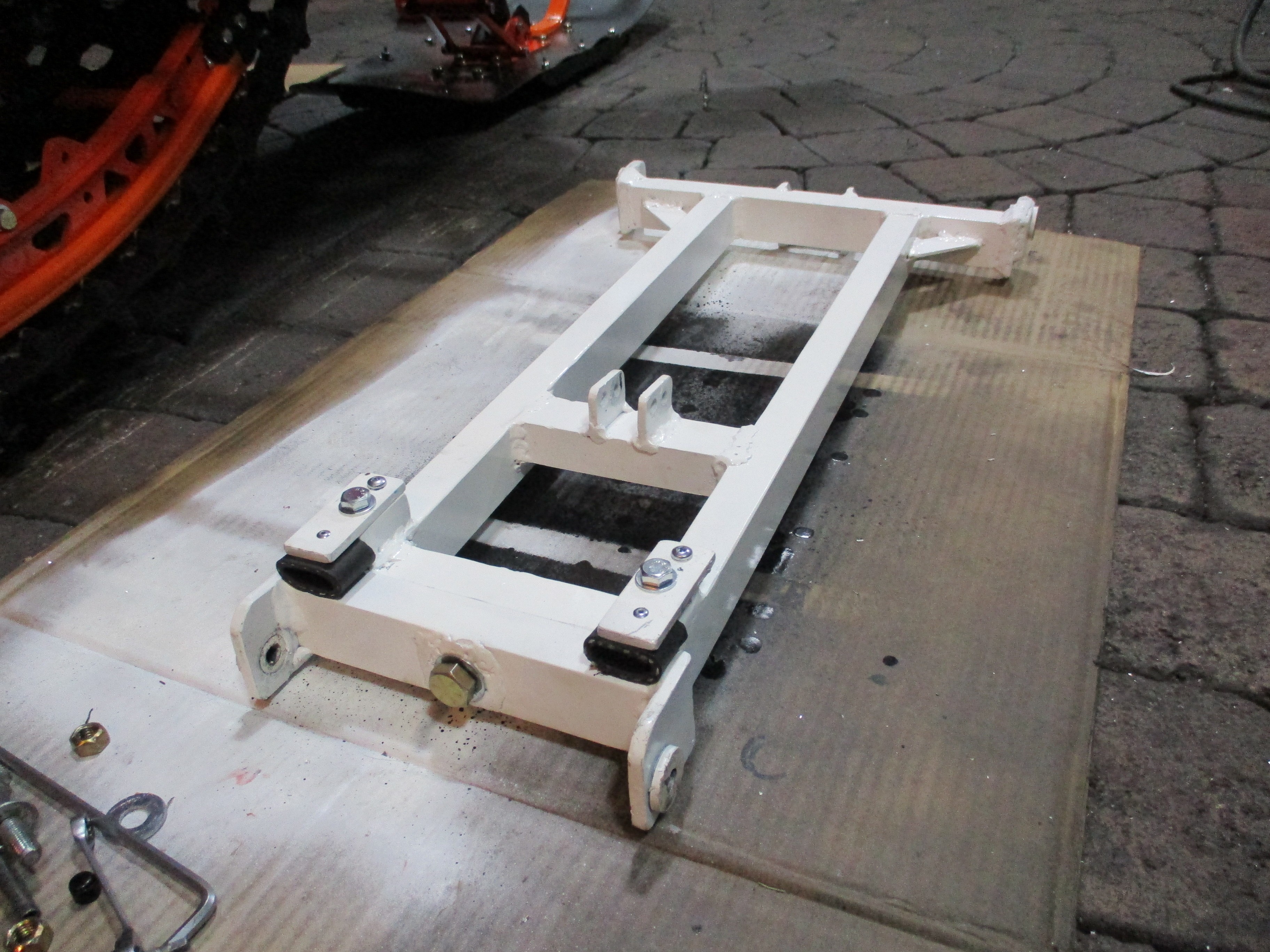

Full rear suspension (with upper and lower casters) weighs 21.3lbs

The chassis with all engine, transmission, support. Weighed only 25.3lbs. As the whole structure is triangulated, it is going to be quite solid.

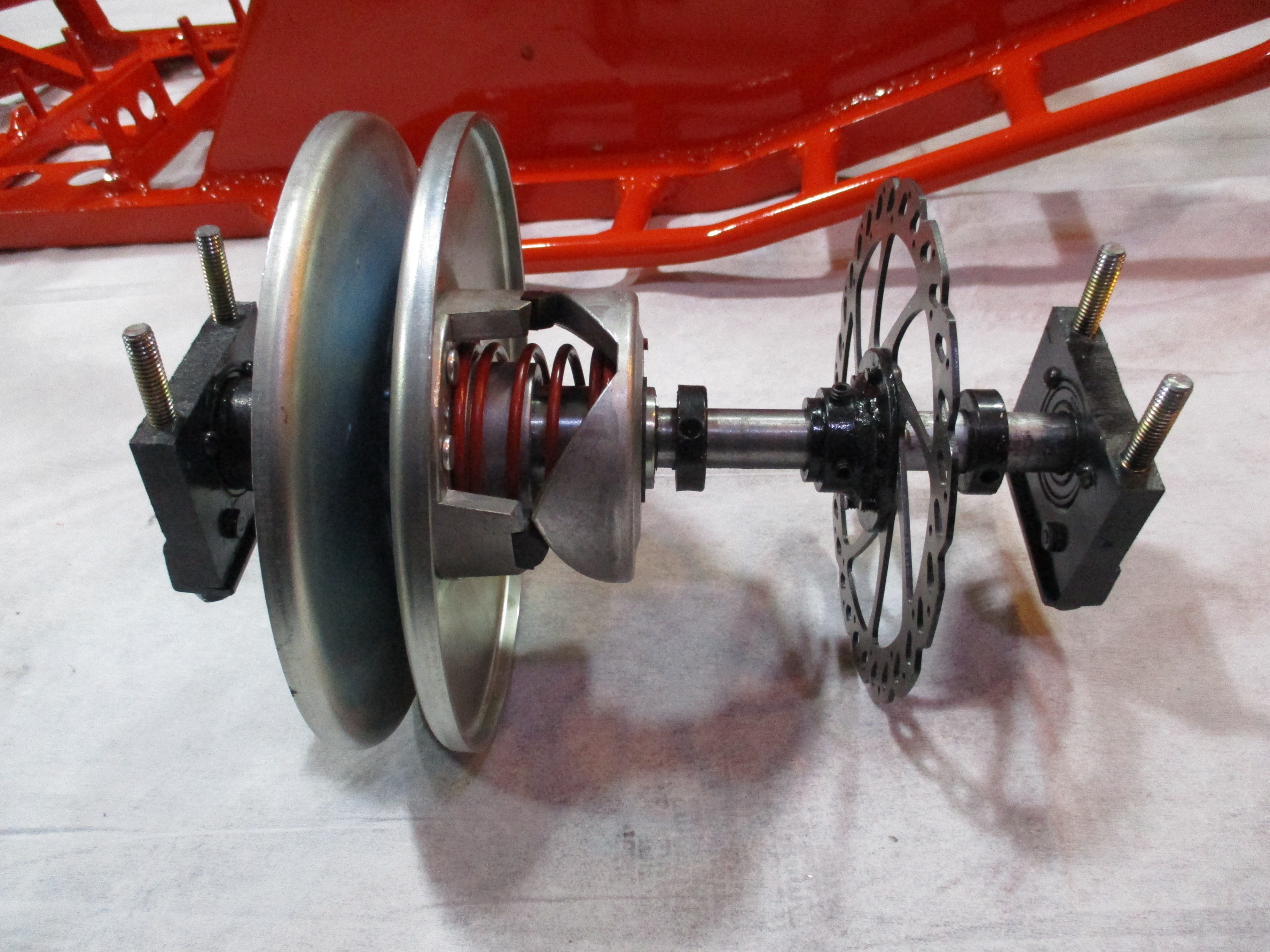

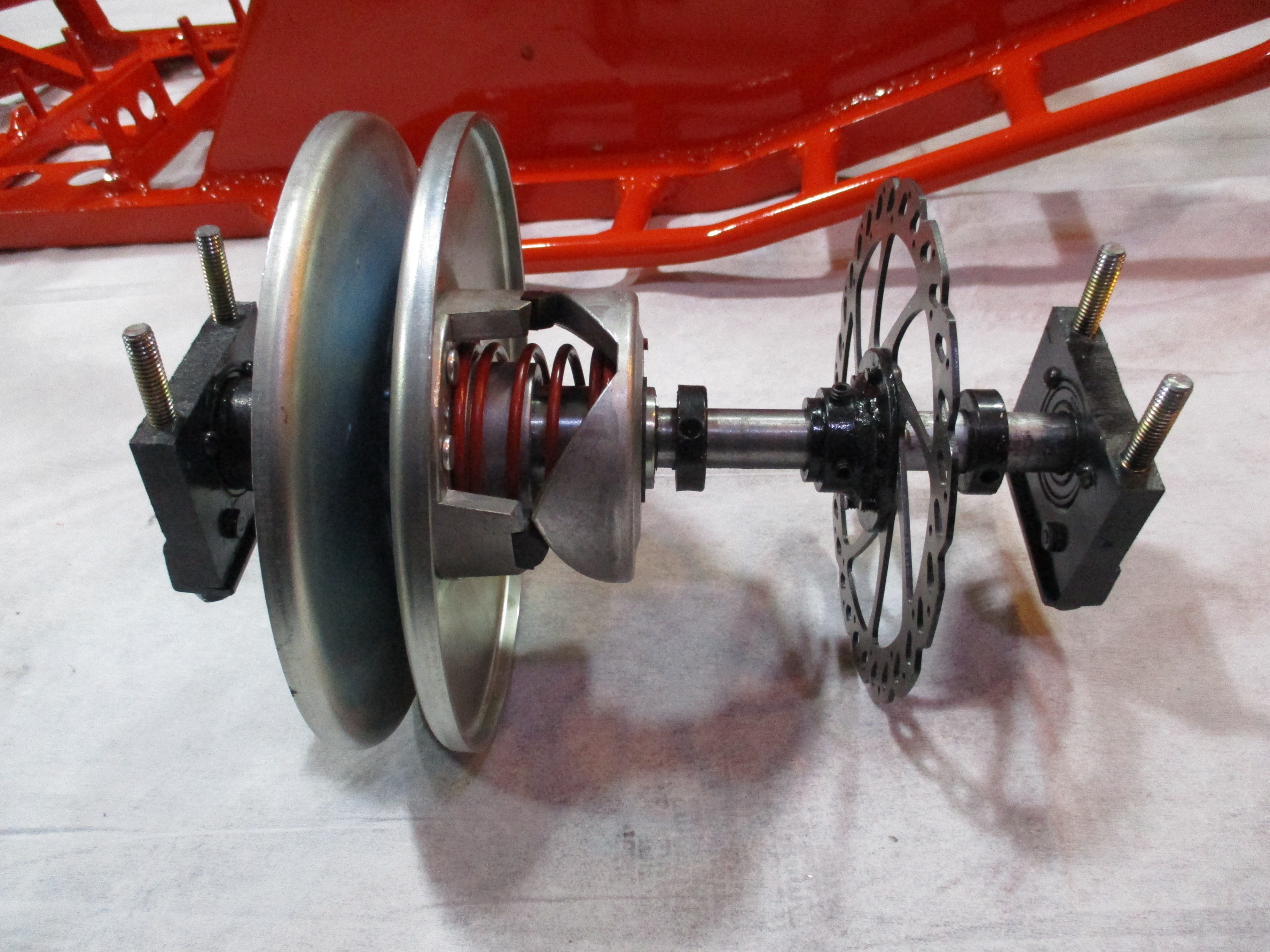

Mono-shock front suspension a bit like the old Yamaha TSS, but 10 times lighter. A motorcycle fork would have been simpler and the design would have been less complicated. But the weight would have been much higher and above all I would have had to put the handlebars and the seat further forward (otherwise the fork would have leaned against the engine when turning) so less traction. Or put the engine between the seat and the tunnel, the seat would have been too high to go under the pipes and I absolutely wanted to be able to put both feet on the ground. Since the monoshock is mounted just 8 "above the ski, it doesn't need to be as sturdy as if it would have been mounted 40" higher extended to reach the ground.

The center of gravity is very low, I did not even need to put it on a block the last stages of construction, it stands very well on its own in the garage, despite the round profile of the track and it there are no strings touching the ground on the edges of the ski. So it should be easy to bring back when it tilts.

It remains to be seen whether I will like the ride and or be able to adapt, at low speeds the balance is tiring to maintain.

In order to have even more places to have fun in the woods, sneak even more into narrow places with limited heights, SIDE hill or not than the Small-Doo. Instead of having to travel hours and hours on the road to find open terrain in the mountains and untouched.

I also can't wait to see the effect of the ski compacting the snow in front of the track a bit, compared to a snowmobile compacting and pushing snow under the skis, but this expended energy and traction is not used by the track that sees fresh snow.

At 180.5lbs with gasoline, that's near half the weight of a 450 Snow bike with one the same length (137)

The rider's weight is on the track, unlike a snow bike whose weight is just in front of the track, which makes a big difference in traction and flotation at low speeds. This also allows you to have a very progressive attacking angel. Disadvantage, the ski has less bite given the low proportion of weight supported on it.

So although the Small-doo BMX track is small compared to off-road snowmobiles, the featherweight gives extremely low ground pressure.

At 180.5 lbs, it is about the same weight as my BW208 motorcycle which is extreme because we are talking about 2 small balloon tires vs a long track and the addition of a reverse gear.

It is also the same weight as a small competition motorcycle CRF150R and lighter than a CRF125F These bikes are surely more robust to withstand the mistreatment of the competition but we are still in the very small vehicle without track to have a comparable weight.

A Timberland kit weighs 137 ’’ weighs 121lbs at the rear (track suspension, tunnel and adapters) and 16lbs for skiing I couldn’t have built from that to get a total of 180lbs

The 136 "track with curved profile (2.5" center) is quite heavy with its stiff studs, 41lbs, almost double the weight of the frame. Too bad I am not equipped to vulcanize a track.

He had to have a line a style, despite it being unlike anything out there. Carbon fiber insertions between the structure, light and very ventilated side panels, which closes with a single push button, much faster than the multi panel systems, several clips that there are on Cie snowmobiles, they will prevent snow and ice to accumulate around the mechanics .. Bumper front to give continuity to the line and to have a good grip, it can be mounted alone in a peakup box (with a ramp) without the engine help.

I had to use a small engine block to have an ideal distribution (sitting on the track, good angle of the handlebars, low seat, all the mechanical transmission that fits in 14 "wide!)

Engine parts Similar to a Honda GX200 which only has 6.5hp at 3600RPM, but it is a 3 '' big bore Tillottons base and crankshakt stroker which gives 252cc, I enlarged and changed the angle of the head to have a flow at 28 '' almost 3 times that of a GX200 head (the valves are also bigger) The compression ratio is much higher, all forged parts inside. So about 25hp at 7000 RPM.

Home made front rear transmission, only the outside of the sprocket, chains and bearing were purchased. So a lot of small parts to build and a lot of adjustments. The whole thing weighs 8.5lbs, but if it had only been walked before it would have needed a much bigger socket at the bottom as there wouldn't have been any secondary gear, a good 2lbs more.

The rear drivetrain therefore adds 6.5lbs. These are X ring chains, so frequent oiling is not necessary. If there had been a strong enough lightweight drivetrain that would fit under the seat while still leaving room for the carburetor at a reasonable price, I would have bought it. A tiny lever that drives a cam allows you to switch from front to back.

The aluminum drive shaft, the UHMW bearing brackets and barred by small steel plates, which forgives small errors in parallelism and is much less heavy than Pillot bearings. There is less than 0.02 ’left between the components to keep the tunnel narrow without putting a chain case.

I made all the wheels to save a few lbs in total, with smaller than standard bearings.

Full rear suspension (with upper and lower casters) weighs 21.3lbs

The chassis with all engine, transmission, support. Weighed only 25.3lbs. As the whole structure is triangulated, it is going to be quite solid.

Mono-shock front suspension a bit like the old Yamaha TSS, but 10 times lighter. A motorcycle fork would have been simpler and the design would have been less complicated. But the weight would have been much higher and above all I would have had to put the handlebars and the seat further forward (otherwise the fork would have leaned against the engine when turning) so less traction. Or put the engine between the seat and the tunnel, the seat would have been too high to go under the pipes and I absolutely wanted to be able to put both feet on the ground. Since the monoshock is mounted just 8 "above the ski, it doesn't need to be as sturdy as if it would have been mounted 40" higher extended to reach the ground.

The center of gravity is very low, I did not even need to put it on a block the last stages of construction, it stands very well on its own in the garage, despite the round profile of the track and it there are no strings touching the ground on the edges of the ski. So it should be easy to bring back when it tilts.

It remains to be seen whether I will like the ride and or be able to adapt, at low speeds the balance is tiring to maintain.