E

EricW

Well-known member

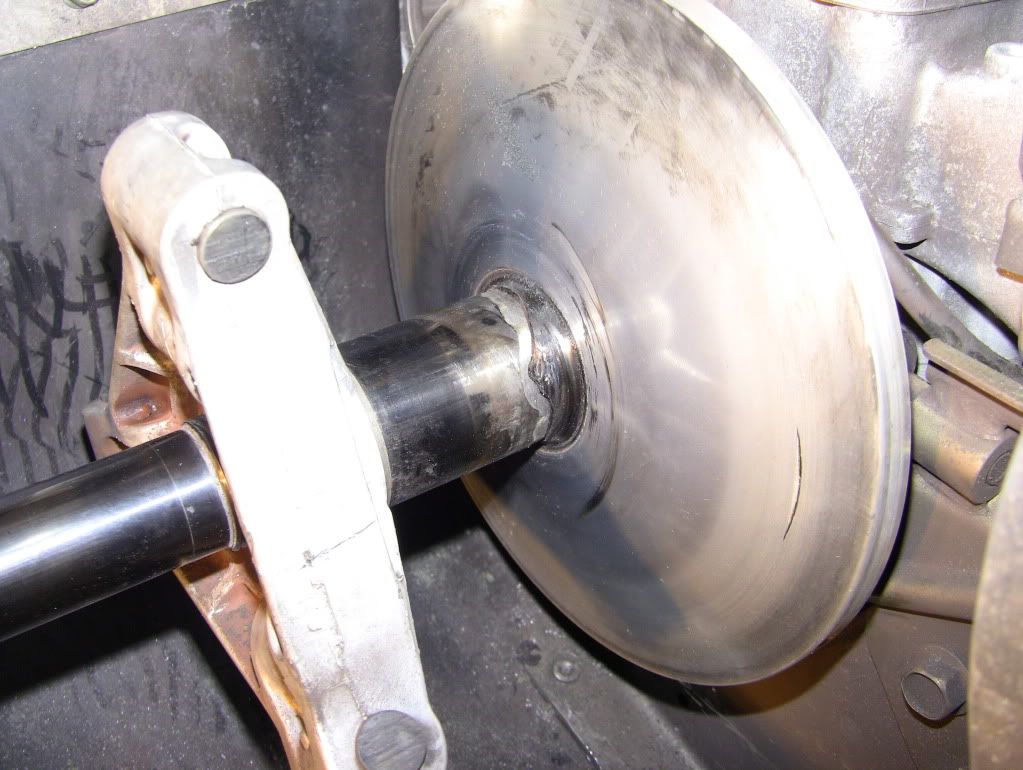

Son #2 broke the primary on his TD8 at the hub almost all the way around. The sheeves are no longer parallel to each other and opened up on one side by 1-2 inches if measuring sheeve to sheeve. The bolt is intact but badly bent.

I was thinking of removing the bolt and then trying to align the sheeves back up enough to weld the hub and be able to use a puller tool. Questions:

1. Will welding "set" the taper of the hub/crank making it impossible to pull.

2. Will a welding lead ground enough through the sheeve or will it need to be direct to the hub.

3. Should I put a wet rag behind the inner sheeve and around the crank to protect the seal from heat, or will the heat kill it anyway.

Any other tips or experience pulling the inner sheeve off the crank following a break like this. I know a cutting wheel is an option but I just know with my luck I would nick the crank. That said do you cut it to a point in that method the use a splitter or some other application to not ding the crank.

Any suggestions are appreciated. Thanks. EW

I was thinking of removing the bolt and then trying to align the sheeves back up enough to weld the hub and be able to use a puller tool. Questions:

1. Will welding "set" the taper of the hub/crank making it impossible to pull.

2. Will a welding lead ground enough through the sheeve or will it need to be direct to the hub.

3. Should I put a wet rag behind the inner sheeve and around the crank to protect the seal from heat, or will the heat kill it anyway.

Any other tips or experience pulling the inner sheeve off the crank following a break like this. I know a cutting wheel is an option but I just know with my luck I would nick the crank. That said do you cut it to a point in that method the use a splitter or some other application to not ding the crank.

Any suggestions are appreciated. Thanks. EW

Last edited: