O

outlaw707

Member

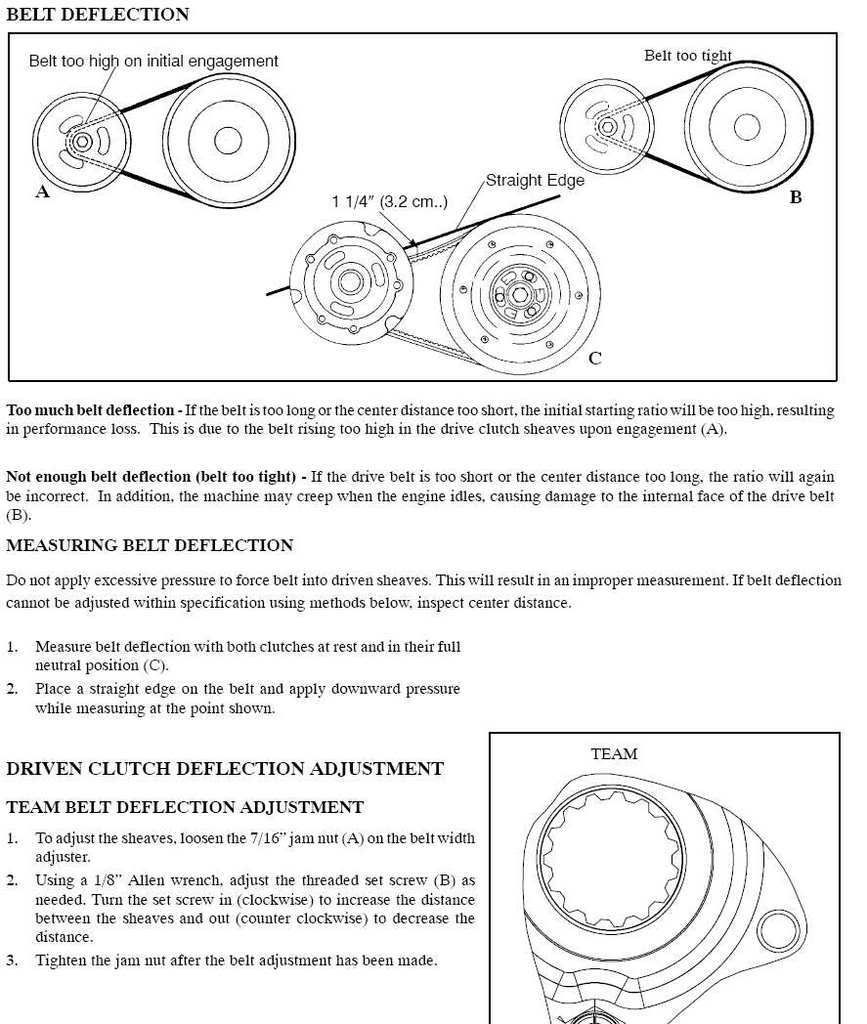

My '14 800 pro has ~40 miles, and i went to adjust the drive belt. The adjustment screw is backed out completely but it appears (its hard to get a true measurement without knowing how much to deflect the belt) a little slack.

The track doesn't engage until around 3000rpm, is this normal?

The track doesn't engage until around 3000rpm, is this normal?