Have you ever wondered why some sleds are easier to ride than others? In the following sections I will discuss how sled design has evolved over the years. For riders in the West the snowmobile manufacturers have taken the sleds originally designed for riders in the flatlands and evolved them into a whole new "species" to make riding in the mountains natural, especially for women.

Have you ever wondered why some sleds are easier to ride than others? In the following sections I will discuss how sled design has evolved over the years. For riders in the West the snowmobile manufacturers have taken the sleds originally designed for riders in the flatlands and evolved them into a whole new "species" to make riding in the mountains natural, especially for women.

So let's talk about this evolution in design and show how the latest 30 percent geometry concept like the ProClimb chassis from Arctic Cat might well define how sleds will be built in the future by all manufacturers.

Sled design in the last 10 years has focused on the engineering term of "centralized mass." This fancy term refers to what riders know as "weight." Weight = MASS (matter) X GRAVITY (9.81 m s - 2).

The feel of weight is manipulated "away" from a rider when both sled and rider achieve balance into one common point together. This manipulation of weight is achieved through chassis design, suspension performance and rider position. Believe it or not, this is even more important than the sled's actual weight.

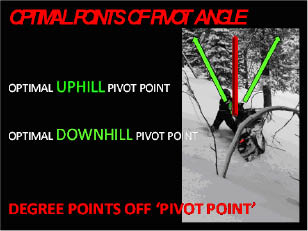

When a rider crosses a common point while counter steering (skis turned opposite the direction of travel), he no longer feels the weight of the machine. We refer to this "feel" of eliminating weight as a pivot point of reference that a rider crosses over and finds himself in a balanced area between the two. The pivot point area is where the relation of the rider's input is working in unison with the sled's center of gravity. This balancing act allows the sled to "tip and roll" or handle with minimal rider input.

Since early 2002, the manufacturers have established a new objective when designing sleds. This objective has been to improve sled performance by managing centralized mass. This is a concept now employed throughout the powersports industry, including motorcycle and ATV designs. For the rider, these changes now require us to change the way we provide input to the machine as well as our body position while riding. Changing our riding style allows us to take advantage of this new relocated "pivot point." The benefit is increased confidence and considerably less energy expended when riding western terrain.

In older chassis designs, the pivot point was more of an area or region and not defined as a single center point at one location. The older design required more strength and rider input to keep up with these pivotal balance points as they continually changed with terrain and snow conditions and were not conducive to someone like a small framed female rider to handle easily.

In older chassis designs, the pivot point was more of an area or region and not defined as a single center point at one location. The older design required more strength and rider input to keep up with these pivotal balance points as they continually changed with terrain and snow conditions and were not conducive to someone like a small framed female rider to handle easily.

The newer and more advanced chassis designs became, the more these two points became more localized, stable and predictable. The circumference distance between the right and left pivot points became a smaller radius area between these two points as well. There have been three angulated points of reference toward chassis structure and design-60, 45 and 30 degrees-over the years. As these chassis angulations have become smaller, we found it reduces the need for rider movement and exertions. A rider must complement these angulations through rider input to achieve correct rider-to-sled angulations.

This isn't as complex as it may sound. Let's look at what has happened over the years.

This isn't as complex as it may sound. Let's look at what has happened over the years.

There have been three major chassis designs in the last 10 years.

1) The oldest design is the trailing arm and torsion spring design. This design required a rider to apply a great amount of physical extension, positioning adjustments and initial input to bring the sled up into the "pivot points area" and was not easily ridden by a small-build male or typical female rider. This sled design had zero to very little centralized mass and a primitive suspension design that came from an existing trail sled chassis. The actual geometry of older trailing arm chassis had really not been drastically changed from the trail version models. The result could not achieve a constant centralized point of gravity needed for a mountain sled. The front and rear suspensions of the trailing arm designs from those trail chassis sleds hindered overcoming steep terrain or deep snow technical riding performance. To reach and maintain a pivot point on this chassis required an enormous amount of rider effort and 60-degree rider-to-sled angulated input.

2) Following the trailing arm concept, the industry migrated to the A-arm design and the rear torsion spring design was replaced with air and/or coil-over shocks. When Arctic Cat released and refined the M Series in 2006, this design had the backcountry mountain rider in mind. This design was an industry leader, changing the market. Because of the demands of the old chassis designs, snowmobiling was a male-dominated sport, due to the cumbersome handling design. The easy riding Arctic Cat M7 opened the gates to the smaller framed riders along with bringing women into the industry to a greater degree. By going to the A-arm design it created a stable pivot point area that stayed between the spindle and the foot well region. This predictable pivot point reduced rider input and exertion. Taking this new approach on a sled's suspension design allowed effective performance in deep snow and steep terrain for even the smallest riders like a 10-12-year-old. Simple but important changes allowed the front suspension to crawl and overcome terrain initially while the rear suspension maintained a healthy track speed by eliminating heavy snow buildup between the track and tunnel area. All OEM A-arm style chassis until 2011 were referred to as a 45 percent chassis because now a rider's angulated input only required 45 degrees of motion.

2) Following the trailing arm concept, the industry migrated to the A-arm design and the rear torsion spring design was replaced with air and/or coil-over shocks. When Arctic Cat released and refined the M Series in 2006, this design had the backcountry mountain rider in mind. This design was an industry leader, changing the market. Because of the demands of the old chassis designs, snowmobiling was a male-dominated sport, due to the cumbersome handling design. The easy riding Arctic Cat M7 opened the gates to the smaller framed riders along with bringing women into the industry to a greater degree. By going to the A-arm design it created a stable pivot point area that stayed between the spindle and the foot well region. This predictable pivot point reduced rider input and exertion. Taking this new approach on a sled's suspension design allowed effective performance in deep snow and steep terrain for even the smallest riders like a 10-12-year-old. Simple but important changes allowed the front suspension to crawl and overcome terrain initially while the rear suspension maintained a healthy track speed by eliminating heavy snow buildup between the track and tunnel area. All OEM A-arm style chassis until 2011 were referred to as a 45 percent chassis because now a rider's angulated input only required 45 degrees of motion.

3) The new 2012 Arctic Cat ProClimb chassis has taken the 45-degree concept and opened a new era of refined design by narrowing these angulations even further to 30 degrees. What I think is the most noticeable achievement is this latest chassis from Arctic Cat has completely stabilized the pivot point location to one spot located at the newly designed front suspension spindle. Forward of the side panel and bulkhead region, this taller spindle allows for clearance to angle the sled steeply on a slope while supporting the sled weight-now only requiring angulations input of 30 degrees. Just look where you want to go and the sled will take you there with ease.

3) The new 2012 Arctic Cat ProClimb chassis has taken the 45-degree concept and opened a new era of refined design by narrowing these angulations even further to 30 degrees. What I think is the most noticeable achievement is this latest chassis from Arctic Cat has completely stabilized the pivot point location to one spot located at the newly designed front suspension spindle. Forward of the side panel and bulkhead region, this taller spindle allows for clearance to angle the sled steeply on a slope while supporting the sled weight-now only requiring angulations input of 30 degrees. Just look where you want to go and the sled will take you there with ease.

A challenge riders are up against with the current 45-degree A-arm designs is the wider side panel and bulkhead belly region behind the spindle, which lies against the snow while sidehilling or turning in deep snow. The pivot point located normally at the spindle would jump rearward as it would now be a factor in supporting the machine and rider.

A challenge riders are up against with the current 45-degree A-arm designs is the wider side panel and bulkhead belly region behind the spindle, which lies against the snow while sidehilling or turning in deep snow. The pivot point located normally at the spindle would jump rearward as it would now be a factor in supporting the machine and rider.

Sometimes this characteristic would actually lift the sled off the snow, wash out the track and even sometimes throw a rider off to the downhill side of a sled. All previous 45-degree A-arm sleds with the shorter spindle designs and A-arm placement could not perform on a steeper sidehill without turning the skis downhill to "catch" the pivot point as it transferred to the rear of the ski and sometimes as far rearward as the foot well region. The rider and machine's weight was no longer centrally located on the spindle as the weight had shifted from the spindle and transferred to the side panel and belly area of the chassis. These changes sometimes happen quickly, back and forth between these pivot locations, sometimes jumping so quickly the rider would get out of sync with the sled and lose control.

The ProClimb's narrower chassis and forward arms now move freely in front of the side panel and bulkhead area and so these two areas no longer lift the sled off the snow when the sled is in a steep sidehill or turning in deep powder snow. A gained result is a stabilized pivot point (center of gravity) that requires very little aggressive rider effort to maintain sled balance. A rider can sidehill without straining as they no longer have to "bite" into a more aggressive counter steered attitude to maintain steep sidehilling control. Instinctually, this will be very hard to overcome for many riders used to other chassis designs. For the less experienced or female riders, it is a huge attribute as no upper body strength is required. Just "look, tip, balance and drive."

By going to a 30 degree chassis from the original 60 degree chassis, it has created a 30 degree gain in performance. Doing the ProClimb math for a 7-hour ride day: 30 degrees gain X 7 hours riding = 210 percent enhanced design.

By going to a 30 degree chassis from the original 60 degree chassis, it has created a 30 degree gain in performance. Doing the ProClimb math for a 7-hour ride day: 30 degrees gain X 7 hours riding = 210 percent enhanced design.

How many women are always given the husband's "old sled" as he upgrades over the years? He rides easier while she fights to keep up. She ends up not progressing, getting tired and frustrated, and stays home more. Is it not time for the lady of the house to upgrade to a 210 percent easier chassis? That might equate to getting her unstuck 210 fewer times in the future.

I can vouch that at 130 lbs. and 5-foot-6, Arctic Cat took note and put enormous value on what the smaller and not-as-strong rider segment out there needed and then produced it.

As an instructor, I spend an enormous amount time explaining the relationship of rider angulations and how they complement the centralized mass of a snowmobile's design. This is a direct result of the fact that I grew up amongst three generations of engineers and a father who was a retired professor of engineering.

As a result of my upbringing I was able to reach back into a foundation principle that was handed down to me by my dad when I was five. While spending a summer day with him as he built my first swingset out of lodge poles and timber bolts, I remember him instilling this concept I use today for my students. "The importance of any structure's strength is manipulated through polygonal angulations." Now, you're probably thinking, "I don't think he said that to a 5-year-old." You are 100 percent right. However, he did say it in such a way that a 5-year-old could understand it. "Make things out of triangles to support it or move it without effort."

The simplicity of "making it a triangle" is even used today within highly sophisticated engineering departments like that at Arctic Cat.

Look at the Arctic Cat ProClimb. You can you see those articulated triangles throughout the design. Can you pinpoint the obvious points of those triangles that support the centralized mass (weight) as one as they move together between rider and sled? How many individual and combined 30-degree angulations do you see? Now complement that with your effortless rider input and some nice smooth throttle input.