My custom aerocharger turbo HO rev bogs and/or dies when I land from a jump. It acts like it gets a rush of fuel and floods immediately. My guess is the floats are slamming down and pushing fuel out the dial-a-jet. Anyone else experience this with a carbed turbo?

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turbo HO rev bogs/dies with jumps??

- Thread starter rotaxhippie

- Start date

i would be willing to bet your jetted a little on the fat side and your plugging your exhaust every time you land. where is your exhaust dumped at? plugged exhaust makes them lay over in a hurry!

i run a carbed doo motor on boost and my exhaust is coming out of the shock tower with a large slash cut downpipe and its not an issue.

i run a carbed doo motor on boost and my exhaust is coming out of the shock tower with a large slash cut downpipe and its not an issue.

you will see a bit of all that. i have found 3 things on the the mx bikes and sleds. all happen when you land really hard. or run the whoops fast.

1 the floats follow gravity making the carb burble.

2 the fuel start to foam making it that no fuel goes through the jet.

3 fuel plugs up the over flow and choke circut making it act like the choke is on.

with a turbo you also have to realize that off throttle the whole system is in choke mode until the system is seeing boost.

things that you can try are

1 droping you pilot jets one size then open your fuel screws up 1 1/2 turns.

2 drop fuel pressure 2 lbs. refrence boost off pipe ( as per gus)

3, 4 call me the other ones are to complicated to discuss on the key baord. at least it is hard to put into words and explain.

1 the floats follow gravity making the carb burble.

2 the fuel start to foam making it that no fuel goes through the jet.

3 fuel plugs up the over flow and choke circut making it act like the choke is on.

with a turbo you also have to realize that off throttle the whole system is in choke mode until the system is seeing boost.

things that you can try are

1 droping you pilot jets one size then open your fuel screws up 1 1/2 turns.

2 drop fuel pressure 2 lbs. refrence boost off pipe ( as per gus)

3, 4 call me the other ones are to complicated to discuss on the key baord. at least it is hard to put into words and explain.

The exhaust is exiting out the stock exhaust hole, so that would be a simple test to try. I'll jump it on some hard snow (or dirt before winter) and try building a guard underneath for starters. That also makes me wonder if that is what was causing power to fall off while side-hilling to the right in powder. Maybe its not just my intake filter clogging.

brycter, My pilots are sized down already, 12's I think with the fuel screws open all the way or it wouldn't idle. I wish your rev kit was available last year. That would have saved me a season of headaches.

brycter, My pilots are sized down already, 12's I think with the fuel screws open all the way or it wouldn't idle. I wish your rev kit was available last year. That would have saved me a season of headaches.

i guess i do know of some float issues that can occur when jumping, im just going to respond to the parts that i see issues with and have experience with.

12.5 piliots and the air screws all the way out is saying something is wrong with your kit, those are freakin tiny.

go start the thing in the garage and hold your hand over the exhaust. it should stay running with all but the whole thing choked off and plugged up. just stuff to mess with while its still not snowing.

12.5 piliots and the air screws all the way out is saying something is wrong with your kit, those are freakin tiny.

go start the thing in the garage and hold your hand over the exhaust. it should stay running with all but the whole thing choked off and plugged up. just stuff to mess with while its still not snowing.

I don't know how you guys get away with such tiny pilots. Anything below 17.5's it will high idle(lean) @ 4500'. I could probably get away with 15's if I didn't ride below 5500', which is doable, but no testing at the house...

Bryce, the line to the boost controller is on the far right on top of the airbox you sold me. I run 6-9K most of the time with a few 10K if it runs good enough to reach the top. I found a few exhaust leaks that kept me from building any real boost, mainly at the Y to pipe connection.

The sled does idle high at low elevation, but fine up where I ride. The 12.5's only went in because it was groggy in the bottom end, but I eventually figured out it was the wrong ramp angle I had in the primary. Still not sure if the angle is good, but so much better than before.

The sled does idle high at low elevation, but fine up where I ride. The 12.5's only went in because it was groggy in the bottom end, but I eventually figured out it was the wrong ramp angle I had in the primary. Still not sure if the angle is good, but so much better than before.

Good to know that many miles can be put on. Did he notice better hard landing performance with vanes more open?

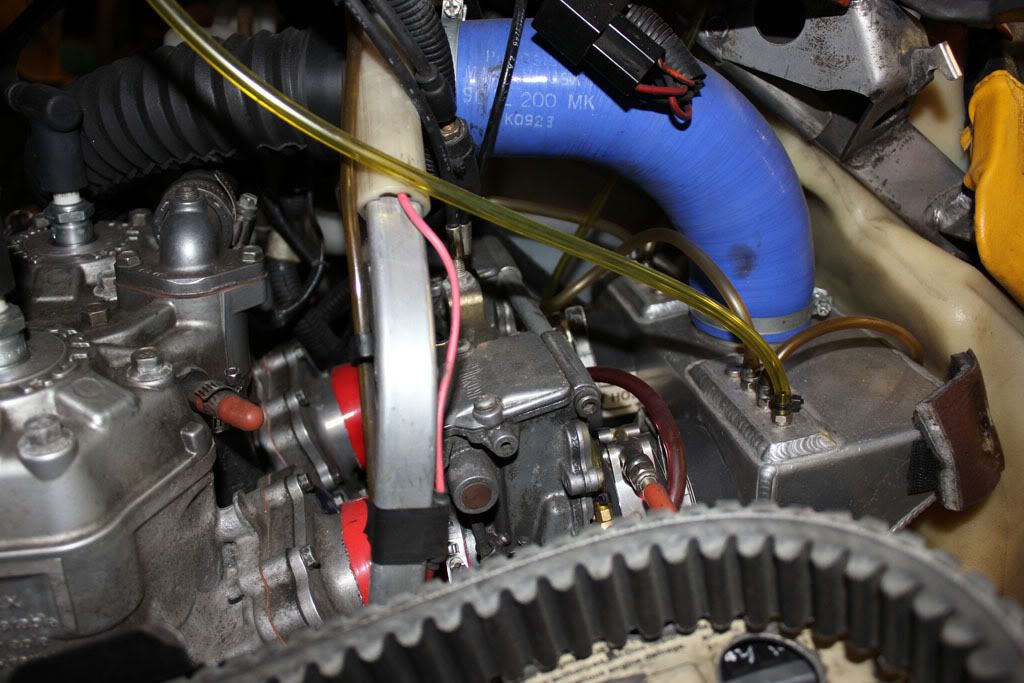

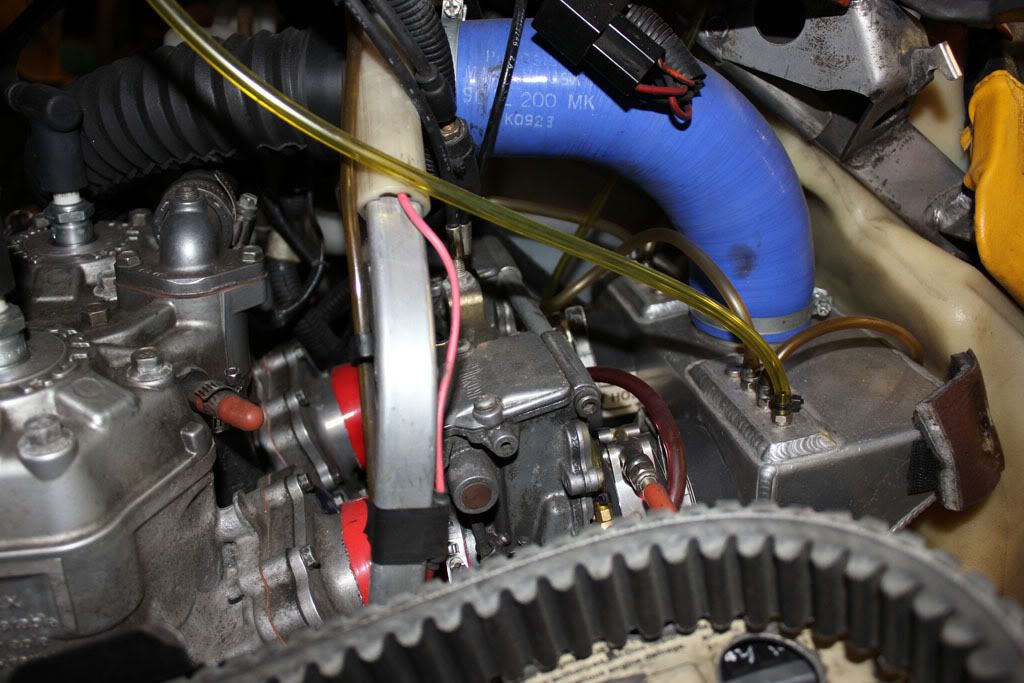

Here are a few pics. I've read that a turbo setup can't have any air leaks anywhere in the system, is that true? When I pressurized the system it was only leaking on both ends of the pipe. Once those are sealed then I may find more. I know my lack of boost was contributing to it running fat, so maybe that goes hand in hand with the boggy landings.

T

turboxp

Active member

leaks

It is true that you don't want leaks they will kill the power that you want and your turbo can't build boost and it won't build it fast.Test your system at what pressure that you want to run it at.Make sure that you don't have a cracked intake boots when testing move carbs up and down sometimes they won't leek until they are moved which they will when you jump .You should also check pipe sometimes pipe will seem just fine cold testing but as soon as you get heat the crack will open check that closely.I am telling you this from my own problems that i have had

It is true that you don't want leaks they will kill the power that you want and your turbo can't build boost and it won't build it fast.Test your system at what pressure that you want to run it at.Make sure that you don't have a cracked intake boots when testing move carbs up and down sometimes they won't leek until they are moved which they will when you jump .You should also check pipe sometimes pipe will seem just fine cold testing but as soon as you get heat the crack will open check that closely.I am telling you this from my own problems that i have had

there is a few problems that i see

1 not enough air going into turbo. through your intake

2 air is tubling through your charge tube. this will slow the flow of air into the motor.

3 kinked line going to your controller on the turbo.

make sure all air leaks are fixed. bellows, pipe, y pipe, grayfoil gaskets, y pipe gaskets,

check and make sure your controller is working on the turbo also. adjust set screw between 2 and 2 1/2 turns in. run and make adjust 1/4 turns as needed. close veins to effect spool up and open to help with run on.

1 not enough air going into turbo. through your intake

2 air is tubling through your charge tube. this will slow the flow of air into the motor.

3 kinked line going to your controller on the turbo.

make sure all air leaks are fixed. bellows, pipe, y pipe, grayfoil gaskets, y pipe gaskets,

check and make sure your controller is working on the turbo also. adjust set screw between 2 and 2 1/2 turns in. run and make adjust 1/4 turns as needed. close veins to effect spool up and open to help with run on.

Cool. I wouldn't have thought to run a pressure test while hot. I'll check the bouncing carbs thing too. I had to use silicone tubing for boots as the Rage cage ones fell apart in a hurry. And I do have an airbox support to the tunnel to limit movement.

Bryce, Did the Frogskin not work with setups you've seen? Initially at first testing I ran it with no filter whatsoever on an open hill and it didn't seem to make a difference. But it has all kinds of issues and I've never built boost above 4 lbs, so maybe it will suffocate it once everything else is taken care of. I do plan to run a 3" flex tube up to a 2 1/2" K&N cone filter for powder. I question the tumbling air through the charge tube as well for performance, but I'll make that change if I can get it to build boost. The line to the controller isn't kinked, however it does make a tight bend, but no so much that it would limit pressure.

I question the aero controller diaphragm as well, even though it is new. I tried using a carb pop-off guage/pump to see if it would hold pressure, but it leaks out as fast as I pump. Maybe its just because I can't keep enough simulated pressure fast enough to get the rod to move. I did play with the controller screw when riding and it made a substantial difference with how fast the boost came on. But my 4 lb max boost isn't all that impressive. or

or

I also read something with the stock XP pipe about cutting out the stinger? Is there a mod like that to be done with a rev pipe while I'm making a new attachment? My pipe has all the seams welded and all I saw was a 2" straight pipe inside at the end.

Thanks guys. Hopefully, I can make this work. I'm don't want to waste another season tuning.

Bryce, Did the Frogskin not work with setups you've seen? Initially at first testing I ran it with no filter whatsoever on an open hill and it didn't seem to make a difference. But it has all kinds of issues and I've never built boost above 4 lbs, so maybe it will suffocate it once everything else is taken care of. I do plan to run a 3" flex tube up to a 2 1/2" K&N cone filter for powder. I question the tumbling air through the charge tube as well for performance, but I'll make that change if I can get it to build boost. The line to the controller isn't kinked, however it does make a tight bend, but no so much that it would limit pressure.

I question the aero controller diaphragm as well, even though it is new. I tried using a carb pop-off guage/pump to see if it would hold pressure, but it leaks out as fast as I pump. Maybe its just because I can't keep enough simulated pressure fast enough to get the rod to move. I did play with the controller screw when riding and it made a substantial difference with how fast the boost came on. But my 4 lb max boost isn't all that impressive.

I also read something with the stock XP pipe about cutting out the stinger? Is there a mod like that to be done with a rev pipe while I'm making a new attachment? My pipe has all the seams welded and all I saw was a 2" straight pipe inside at the end.

Thanks guys. Hopefully, I can make this work. I'm don't want to waste another season tuning.

T

turboxp

Active member

Boost

I dont know if you had problems always but like Bryce says your air will tumble bad in the rad hose that you use for charge tube that will affect how your turbo reacts you want as smooth as possible all will affect the performance of your sled big time.The first air box I built for a xp was smooth but was to tight and the air was fighting itself to get into the motor and created lots of trouble for tunning fixed that and all better same thing can happen with charge tube.

I dont know if you had problems always but like Bryce says your air will tumble bad in the rad hose that you use for charge tube that will affect how your turbo reacts you want as smooth as possible all will affect the performance of your sled big time.The first air box I built for a xp was smooth but was to tight and the air was fighting itself to get into the motor and created lots of trouble for tunning fixed that and all better same thing can happen with charge tube.

I hope my airbox has a good shape. It seems to with the back angled and everything symmetric. I wonder if there is some trade off because the inside of the rad hose does have the washboard feel (much less dramatic than the outside shows), but it makes a nice smooth bend vs. the resistance tighter bends might add. I know an auto exhaust guy that offered to build me a charge tube. So I will definitely be doing that if tuning it is still an issue once I have everything sealed up.

I'm still curious about modding the stock pipe. Is there anything necessary to do to it besides welding the seams? I don't want a third build on it.

I'm still curious about modding the stock pipe. Is there anything necessary to do to it besides welding the seams? I don't want a third build on it.

I have not had the best luck with the stock pipe. I always seemed to be chasing a crack somewhere. The aftermarket pipes with thicker walls work better. I pulled the "internal stinger" out of the tailpipe of mine.

If you can, get your exhaust guy to build you a charge tube with mandrel bends without kinking it. Another option is to use more silicone connectors with straight sections of pipe, downside if more potential leaks...

Honestly, I could never get my 53 aero to spool very fast. I tried added a "cold air intake" with flexible hose. It pretty much killed it! It liked having an open top the best. Maybe that's why they run a open wire screen on their kit...

If you can, get your exhaust guy to build you a charge tube with mandrel bends without kinking it. Another option is to use more silicone connectors with straight sections of pipe, downside if more potential leaks...

Honestly, I could never get my 53 aero to spool very fast. I tried added a "cold air intake" with flexible hose. It pretty much killed it! It liked having an open top the best. Maybe that's why they run a open wire screen on their kit...

Well that bums me out the flex tube doesn't work. Sounds like I need a aero wire screen dome on hand to use if my other filters suffocate too much. That screen is going to let a lot of debris through. There is a lot of floaters in the air that the frogskin filters out.

Good point with the mandrel bends. Irish pointed that out to me as well.

Does the exhaust flow that much better with the stinger removed? I'm confused why it's even in there then. Did it affect bottom end performance with it removed?

Good point with the mandrel bends. Irish pointed that out to me as well.

Does the exhaust flow that much better with the stinger removed? I'm confused why it's even in there then. Did it affect bottom end performance with it removed?

Memory didn't serve me correctly. There is nothing to cut out at the end of the pipe. It flows through without restriction.

Similar threads

K

- Replies

- 6

- Views

- 1K

K

S

- Replies

- 18

- Views

- 3K