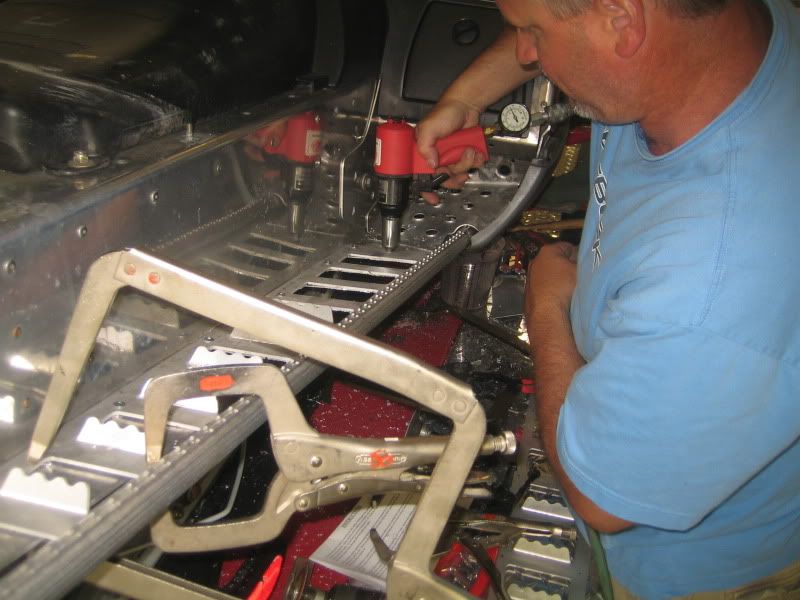

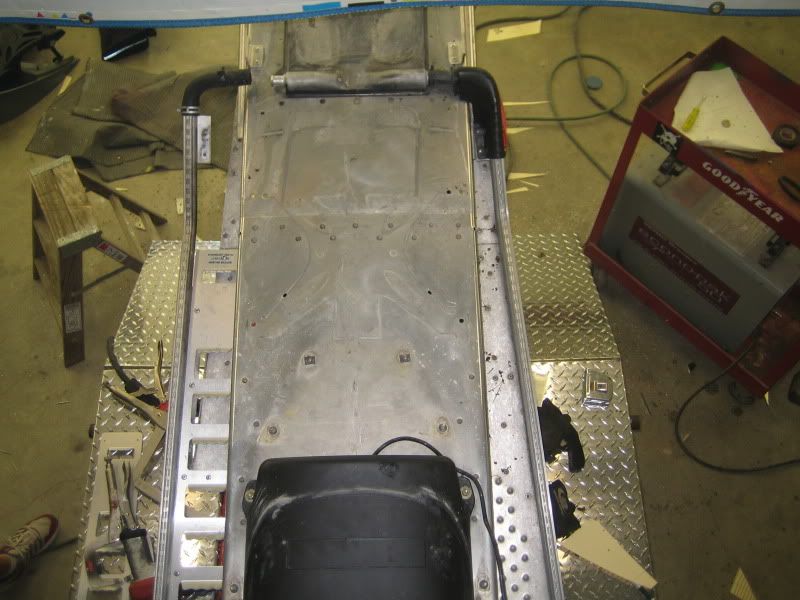

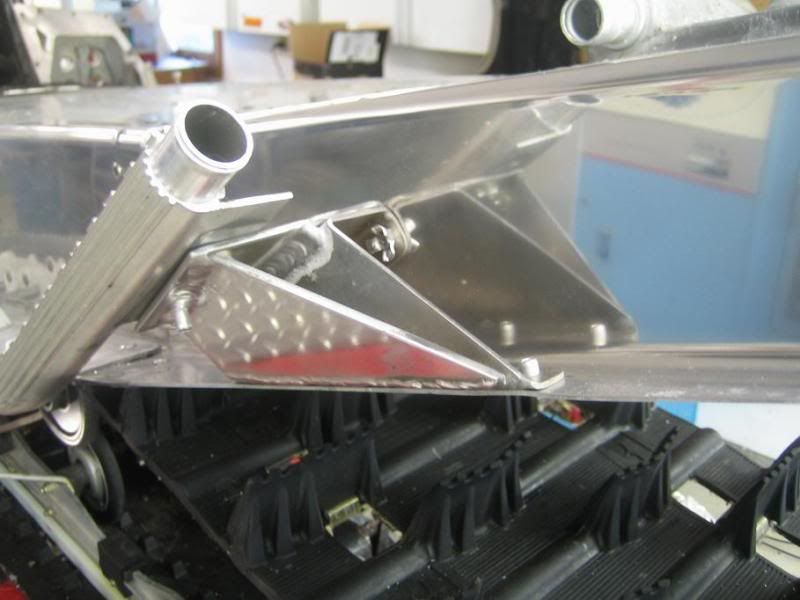

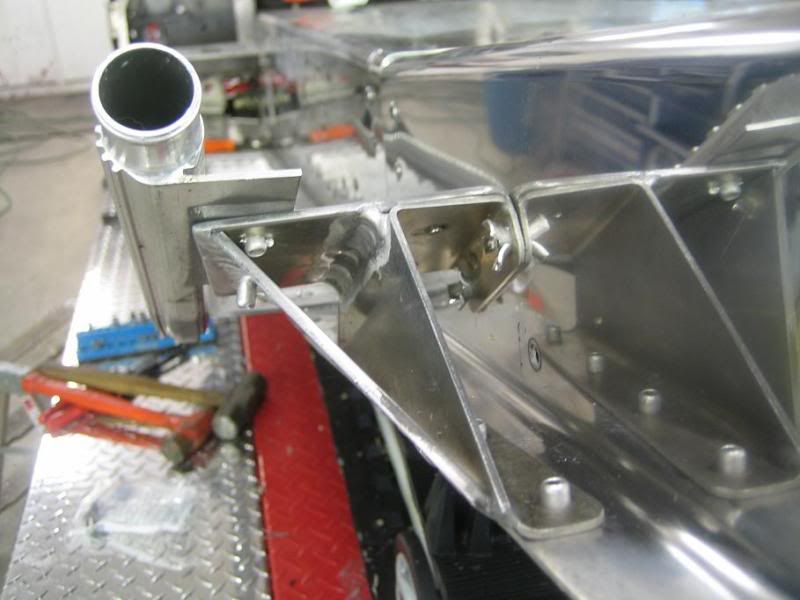

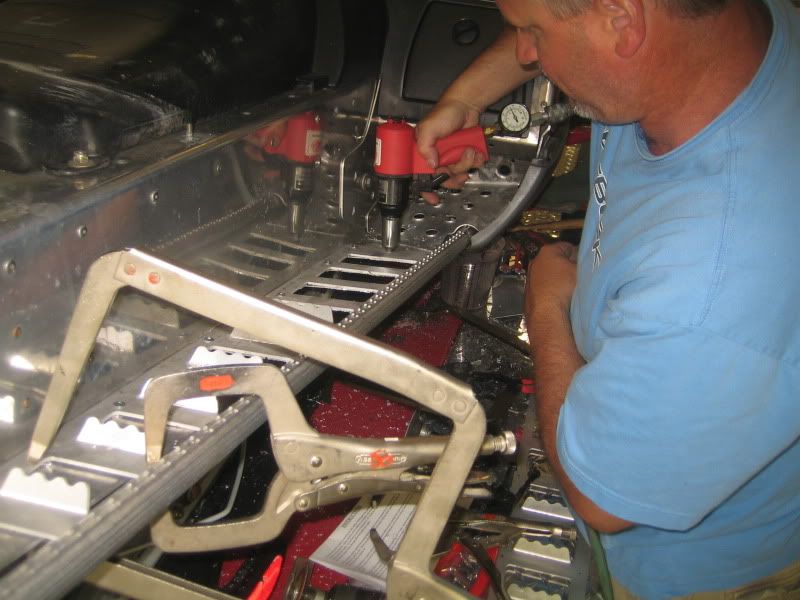

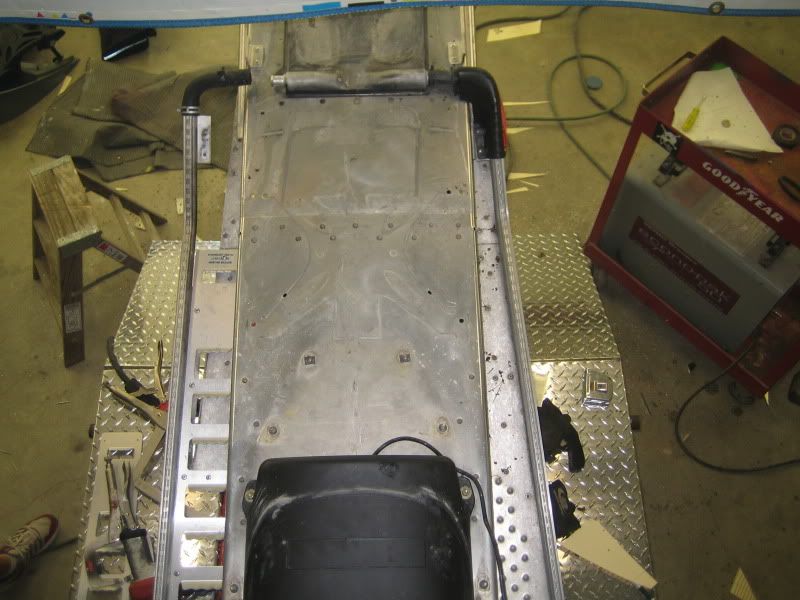

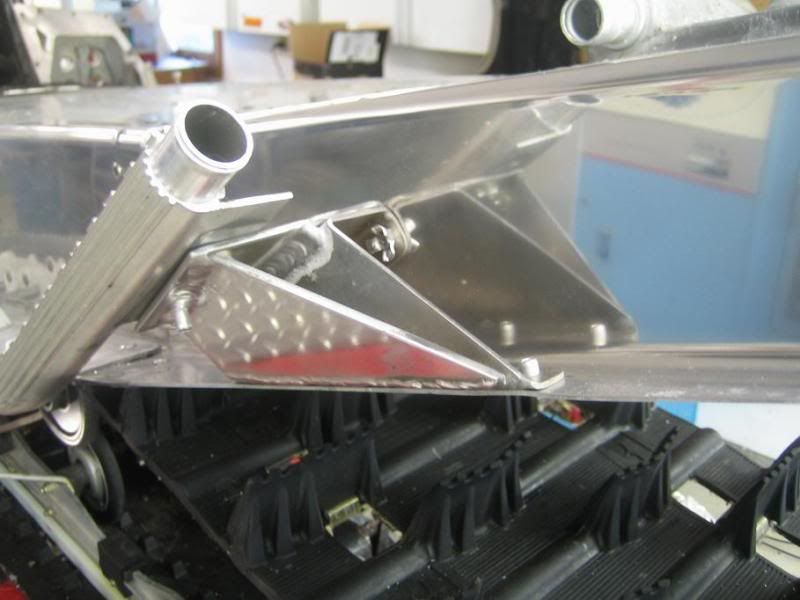

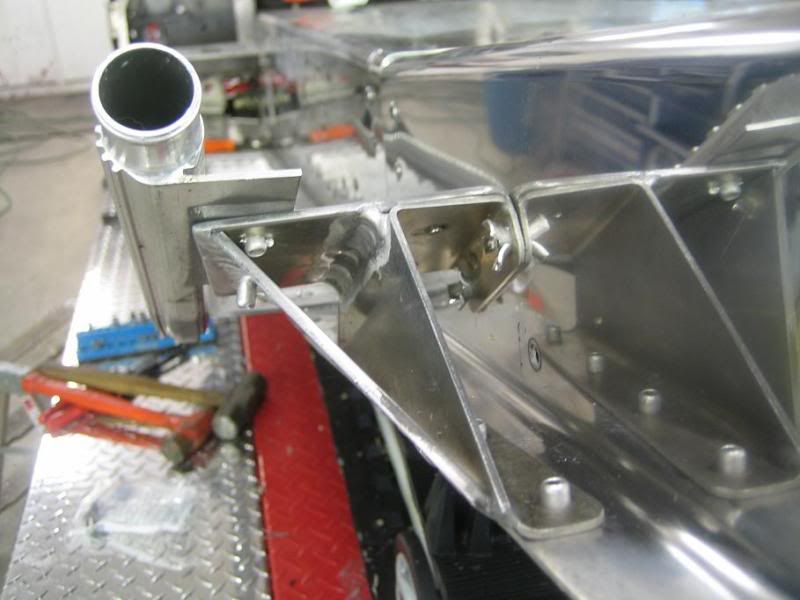

I am one of the die hard 900 riders but the one thing that always made me dislike the chassis was the narrow boards and on top of that always plugging with snow. I picked up a set of Robs Better boards for the newer RAW chassis and put them onto the older one. Makes a real nice set up and you dont have to re-tunnel. As for the coolant line there is an outfit that will make a 7/8 to 3/4 hose for 30 bux a piece and in any color you want. But I had already just ordered the front coolant line near clutch side which can be cut to fit. The rear bracket utilizes the factory bracket but you will have to do some aluminum welding or just cut the pieces and have someone weld it for you. I did talk to Rob about maybe selling those rear brackets pre made so maybe he will doo that for us. Also you cant cut out the last 3 holes as there are support brackets. Maybe if Rob could make a set for the IQ's that have the turn ups on last 3 but not cut out it would make a cleaner look or a guy could put a thin piece of aluminum under it would doo same thing but i didnt have any at the time. As for strength they are just as strong.